Bidirectional anti-skid device for blasting charge

An anti-skid device and charging technology, which is applied in the field of mine blasting engineering, can solve problems such as difficult handling, explosive unit stuck in the middle, easy punching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

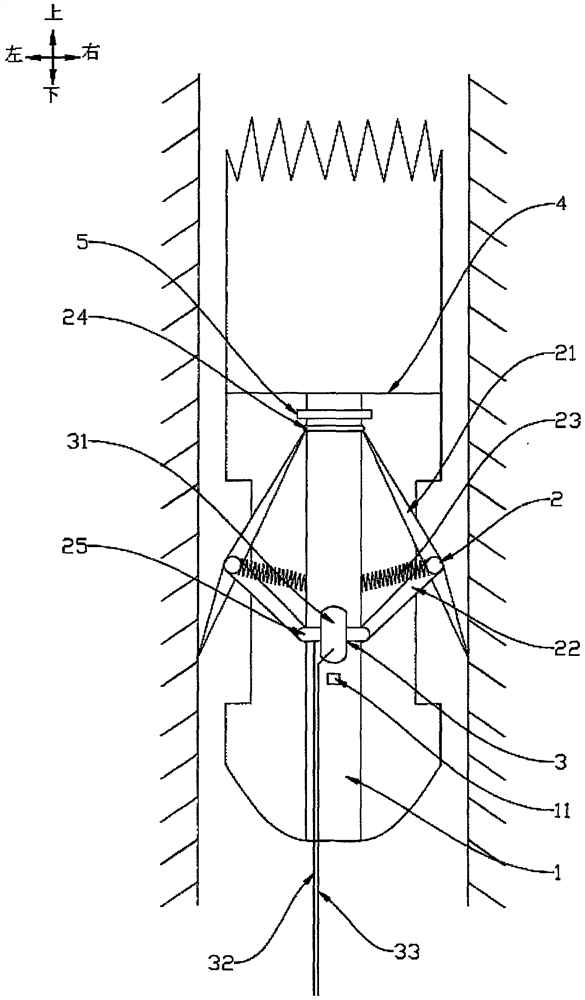

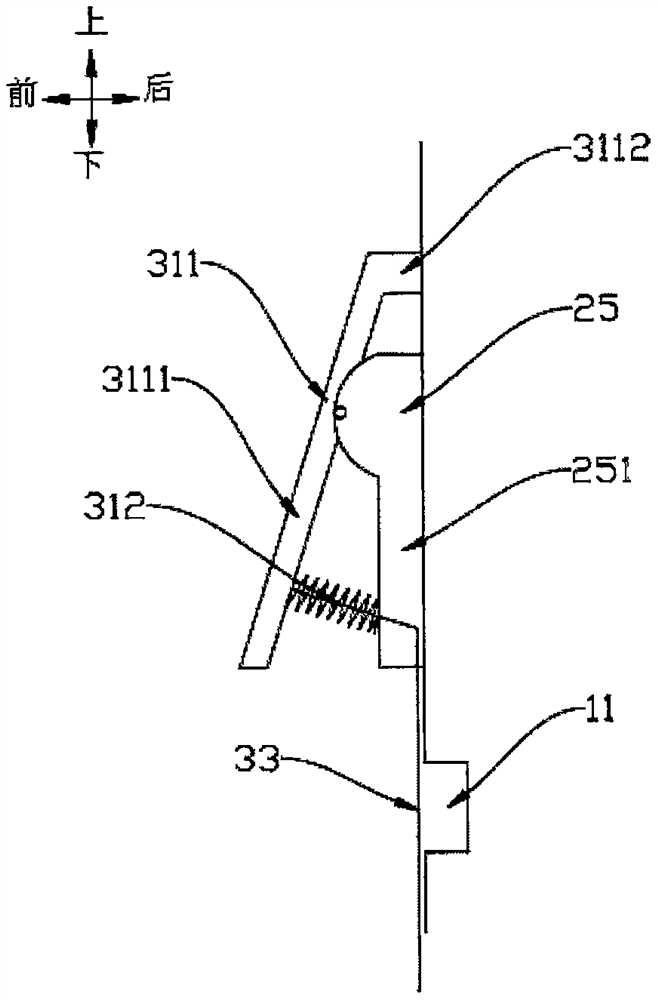

[0021] Embodiments of the invention will be described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0022] The following describes the two-way anti-skid device for blasting charge according to the embodiment of the present invention with reference to the accompanying drawings.

[0023] The two-way anti-slip device for blasting charge according to the embodiment of the present invention includes a guide rod 1, a support assembly 2 and a control assembly 3. The axial ring 24 and the second axial ring 25, the first axial ring 24 and the second axial ring 25 are sleeved on the guide rod 1, and can move along the axial direction of the guide rod 1, and a plurality of fixing parts 21 One end of a plurality of support rods 22 is pivotally connected to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com