Centralized monitoring system for mine hoist cluster

A mine hoist, centralized monitoring technology, applied in the direction of general control system, control/regulation system, instrument, etc., can solve the problems of insufficient response and affecting production, so as to save the number of people, improve efficiency, and achieve remarkable social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

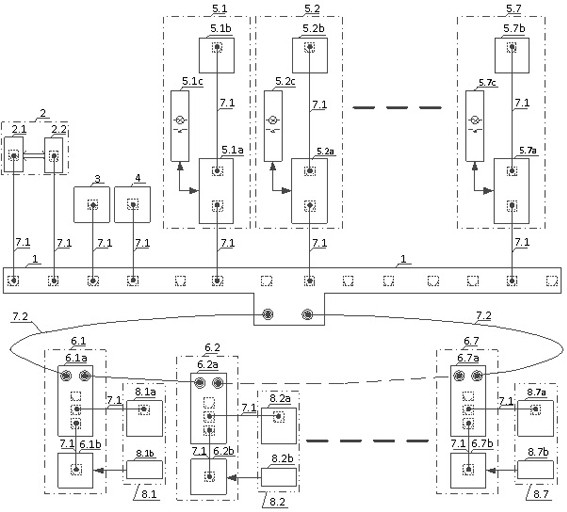

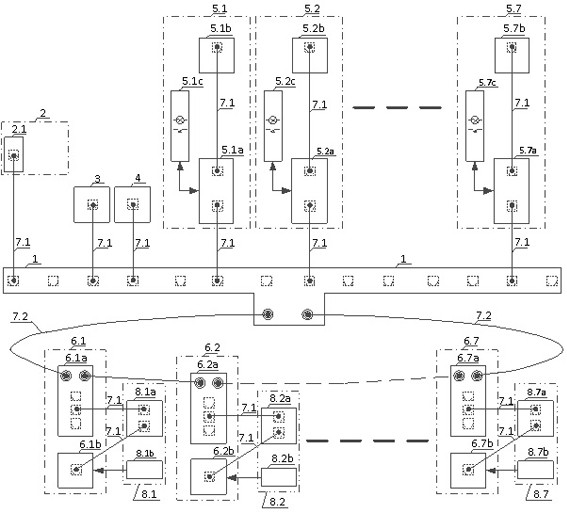

[0025] Embodiment one ( figure 1 ), the PLC I (2) is composed of two CPUs, CPU1 (2.1) and CPU2 (2.2), the CPU1 (2.1) and CPU2 (2.2) can form a redundant or hot standby type, and the CPU1 ( 2.1) and CPU2 (2.2) keep data synchronization at all times, once a CPU breaks down, only an alarm will be issued, and the other CPU will continue to keep the monitoring system in the elevator machine cluster described in the present invention in a good working condition; in practical applications, The PLC I (2) can also be composed of a CPU, namely CPU1 (2.1), see Embodiment 2 ( figure 2 ).

[0026] The difference between embodiment one and two is also that, figure 1 Among them, seven of the PLC III (6.1b~6.7b) are remote substations of the PLC I (2), or small PLCs of the same series as the PLC I (2), for example, the PLC I ( 2) If it is Siemens S7-1500 series, then the 7 mentioned PLC III (6.1b~6.7b) can be Siemens S7-1200 series; figure 2 Among them, the 7 PLC III (6.1b~6.7b) can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com