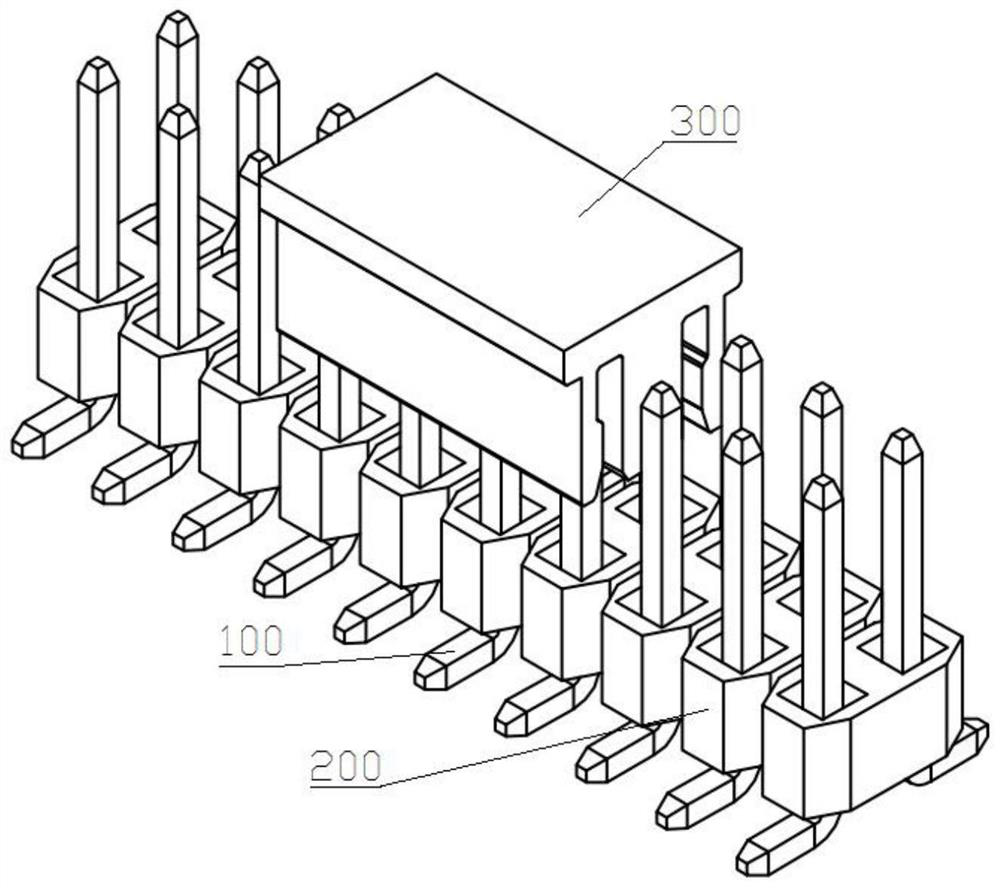

Automatic assembling equipment for electric connector production and processing

An automatic assembly, electrical connector technology, applied in the assembly/disassembly of contacts, etc., can solve the problems of difficult pin clamping and fixing, lack of production and assembly equipment efficiency and stable production quality, and insulators that cannot be quickly assembled. The effect of less dependence on experience and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the technical solution of the present invention will be described in detail below. Those skilled in the art should know that what are described in the following embodiments are only some specific implementation structures or modes of the present invention, rather than all embodiments, and therefore, the protection scope of the present invention is not limited thereto.

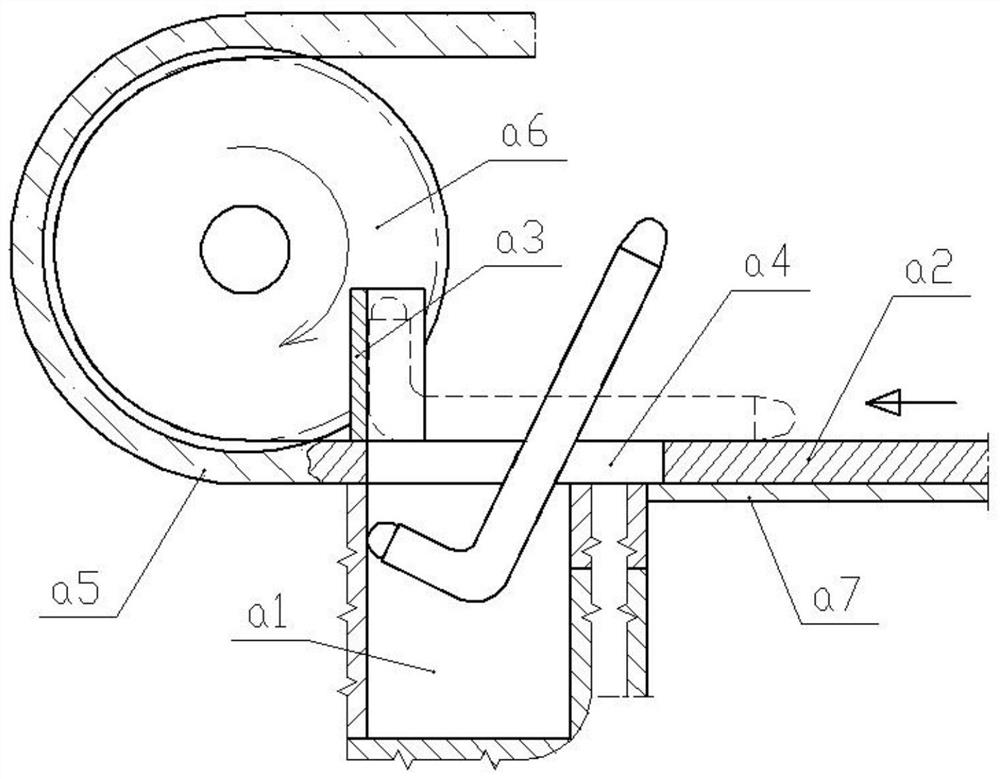

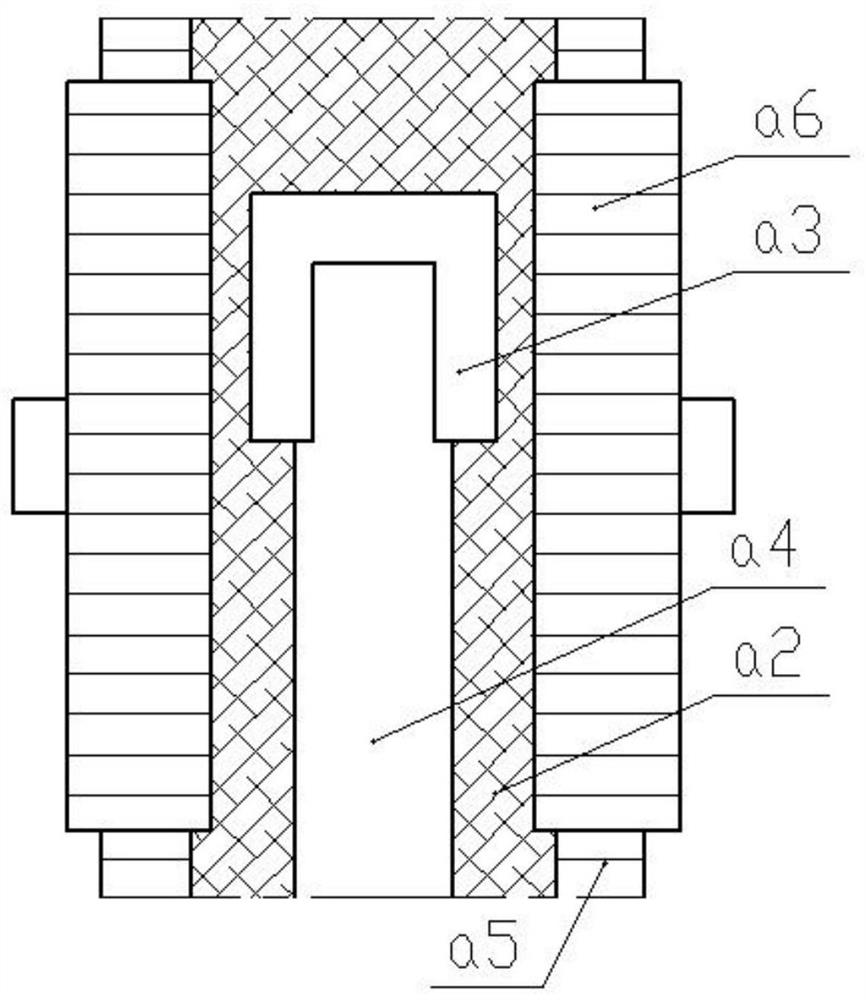

[0025] This embodiment discloses an automatic assembly equipment for the production and processing of electrical connectors. Firstly, it includes an automatic conveying part for conveying the pin 100 into the placement groove a1, see Figure 2-Figure 4 As shown, the structure includes a placement groove a1 for pre-setting the L-shaped pin 100, the placement groove a1 is a flat rectangular parallelepiped structure with an open top. Above the notch of the placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com