Biradial combined type magnetic pole permanent magnet driving motor

A technology of permanent magnet drive and motor drive, which is applied in the direction of motors, magnetic circuit rotating parts, electric vehicles, etc. It can solve the problems of weak magnetic field strength on both sides of the magnetic pole, high magnetic field strength at the center of the magnetic pole, and weak reliability, and achieve magnetic concentration Significant effect, high power density, and the effect of preventing demagnetization of permanent magnet steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

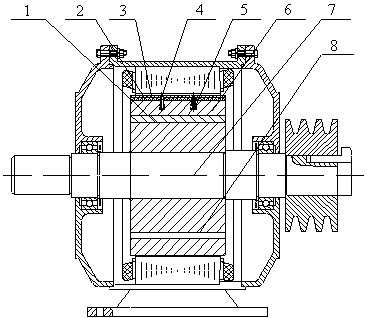

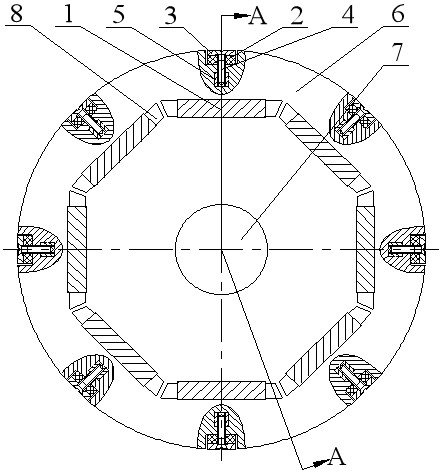

[0012] The double radial combined magnetic pole permanent magnet drive motor is composed of a rotor, a stator, an end cover, and a rotating shaft 7, and is characterized in that: the drive motor rotor is a double radial combined magnetic pole permanent magnet rotor;

[0013] The double radial combined magnetic pole permanent magnet rotor consists of the first rectangular permanent magnet steel 1, the rotor core 6, the pole shoe 3, the second rectangular permanent magnet steel 2, the screw 4, the square iron rivet 5, and the right-angle trapezoidal magnetic isolation air gap 8 , rotating shaft 7, the rotor punch is evenly distributed with a plurality of rectangular slots that are close to the outer circle of the rotor punch and run through the thickness of the rotor punch. The outer side is not connected to the outer circle of the rotor punching sheet. The left end of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com