Flattened ultrasonic motor

An ultrasonic motor, flattening technology, applied in the directions of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. To achieve flat structure and other issues, to achieve the effect of broadening the performance adjustment range, small size, and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

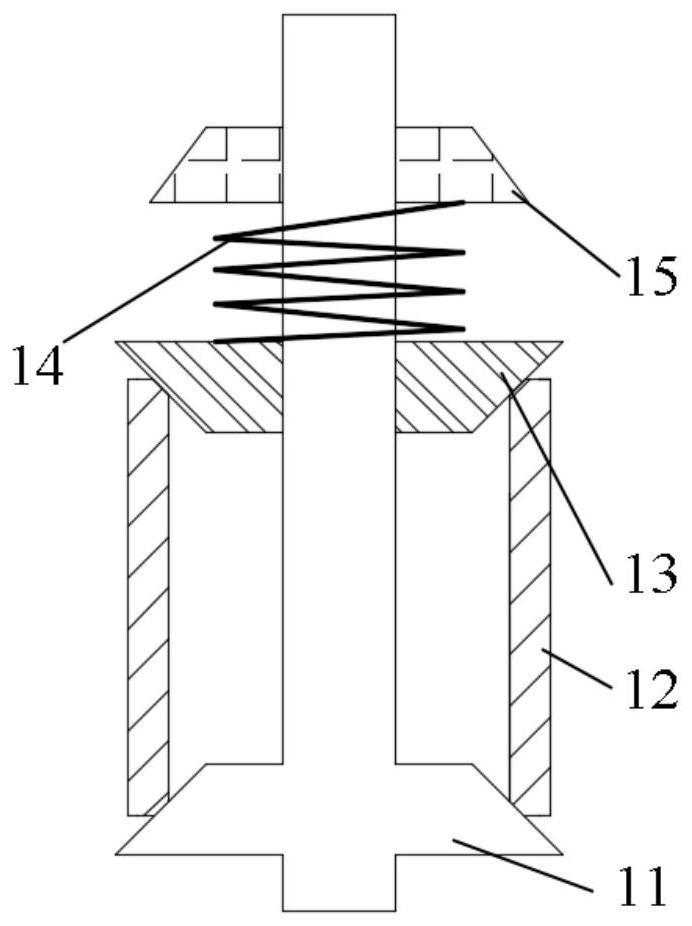

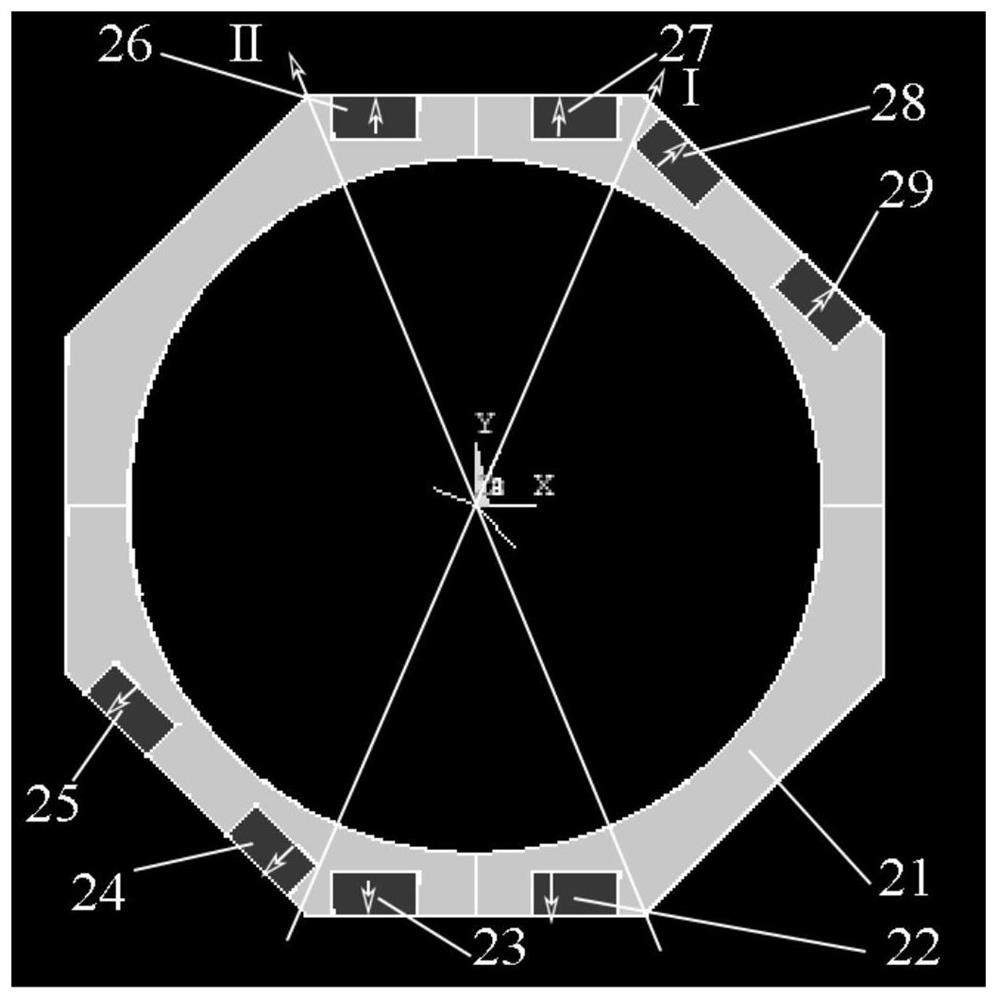

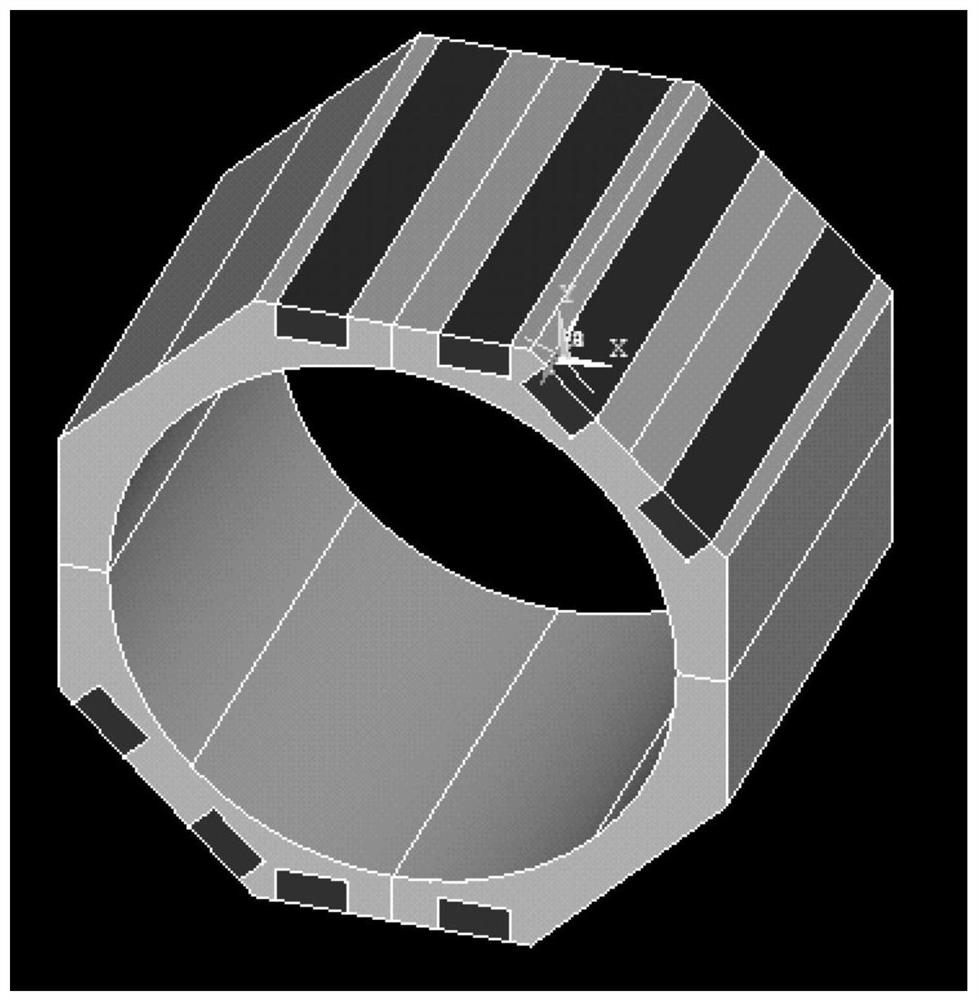

[0034] There is no groove on the stator metal base 21 in Embodiment 1. At this time, the piezoelectric ceramic sheets 22 to 29 are pasted on the outer surface of the stator base 21 by epoxy resin glue, and the piezoelectric ceramics pasted by the stator 12 The positions of the sheets 26 and 27 (22 and 23; 24 and 25; 28 and 29) are close to the two-phase in-plane vibration modes of the stator 12 (such as Figure 4 and Figure 5 shown) in the direction of vibration.

[0035] Similarly, the piezoelectric ceramic sheets 22 to 29 in Embodiment 2 can also be replaced by multilayer stacked piezoelectric ceramics.

[0036] In addition, the embodiment can also figure 2 The position of the piezoelectric ceramic sheets 26 and 27 attached to the stator 12 in the middle is adjusted to be close to the y-axis, and the piezoelectric ceramic sheets 22 and 23 are adjusted successively (close to the y-axis); 24 and 25 (close to the 45° direction); 28 and 29 (close to the 45 ° direction) past...

Embodiment 3

[0038] The number of discrete piezoelectric ceramic sheets is increased on each surface of the stator base 21 in Embodiment 1, thereby further reducing the length of the stator 12 and realizing a flat design of the motor. The number of discrete piezoelectric ceramic sheets on each surface can be between 2 and 5. Usually, the more discrete piezoelectric ceramic pieces on each surface, the smaller the length of the motor, the modal excitation mode of the motor increases exponentially, and the output performance and performance adjustment range of the motor also increase exponentially. The number of piezoelectric ceramic sheets required is also more.

[0039] For the convenience of description, the present invention uses figure 2 The illustrated stator base is taken as an example for illustration, but the flattened design proposed by the present invention is also applicable to in-plane vibration ultrasonic motors working in other in-plane vibration modes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com