System and method for preventing wrong material of raw materials in electronics industry

A technology for the electronics industry and raw materials, applied in the direction of manufacturing computing systems, electrical components, electrical components, etc., can solve problems such as difficult to distinguish feeding angles, reduce production quality, etc., and achieve the effect of preventing product errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

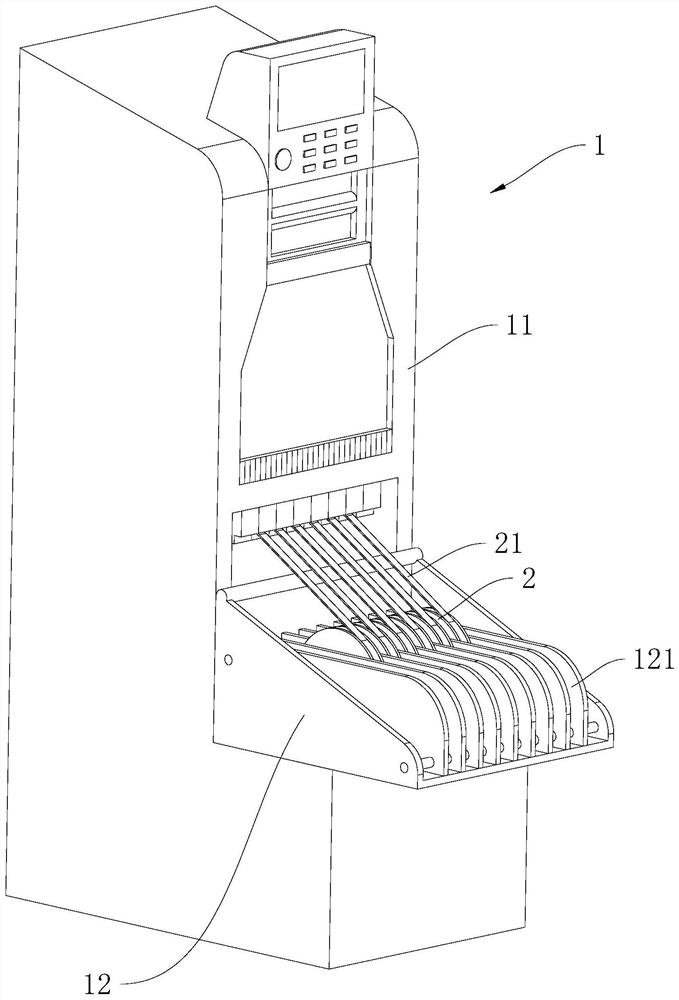

[0055] Referring to FIG. 1 , the station of the existing placement equipment 1 includes a fuselage 11 and a feeding rack 12.

[0058] At the same time, one station only receives one kind of material, and the type, specification, and feeding angle of the material are all consistent.

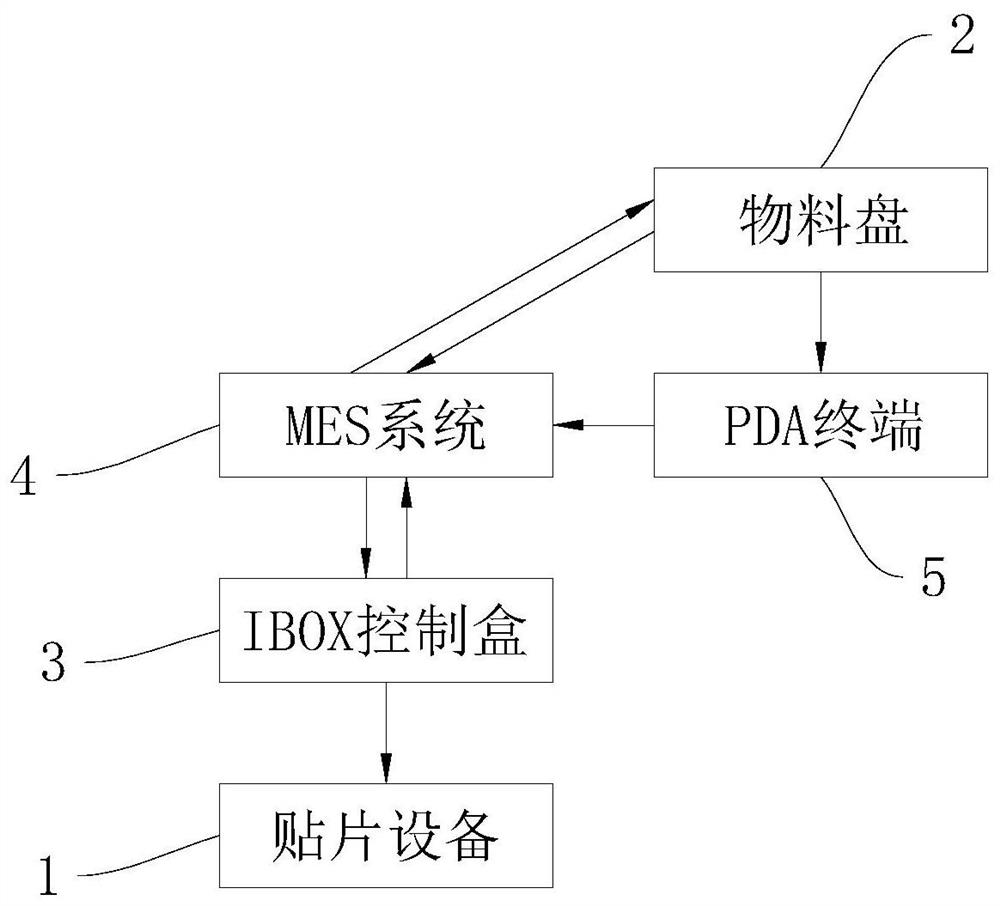

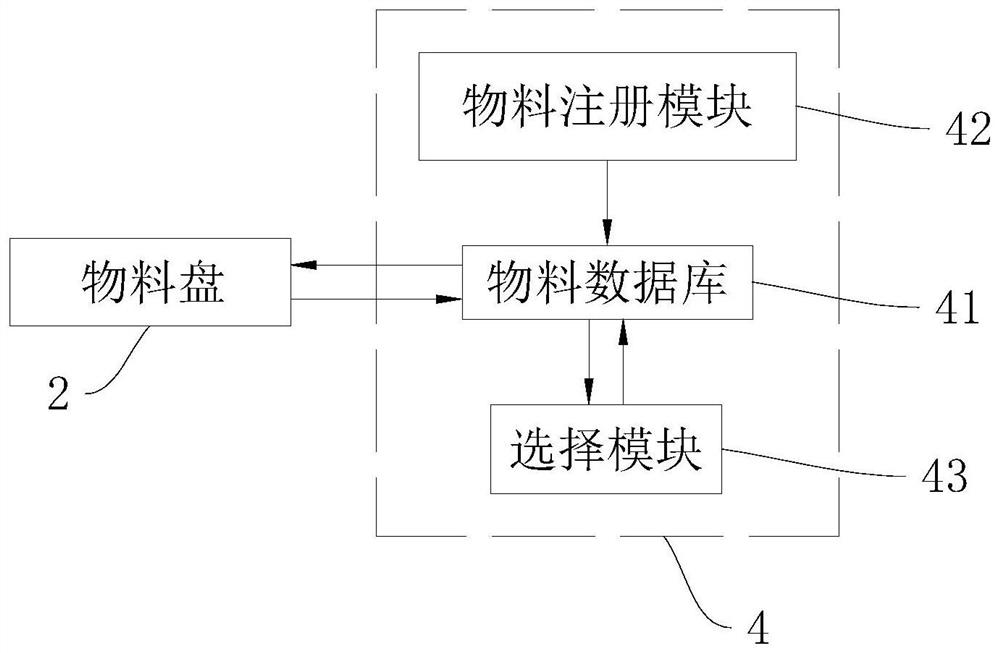

[0067] The MES system 4 also includes an acquisition module 44, a comparison module 45, a verification module 46, and a review and release module 47.

[0075] The verification module 46 responds to the verification signal with the feeding angle information, the specific angle information and the recording angle information,

[0088] The S6 review and release module 47 sends a release signal to the PDA terminal 5, and a person executes S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com