Fluid filter and filtering method

A technology of a fluid filter and a filtration method, which is applied in the field of filtration, and can solve problems such as insufficient filtration effect, required liquid doped with impurity liquid, and impurity of the required liquid, so as to achieve improved filtration effect, high structural integration, and high pressure easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

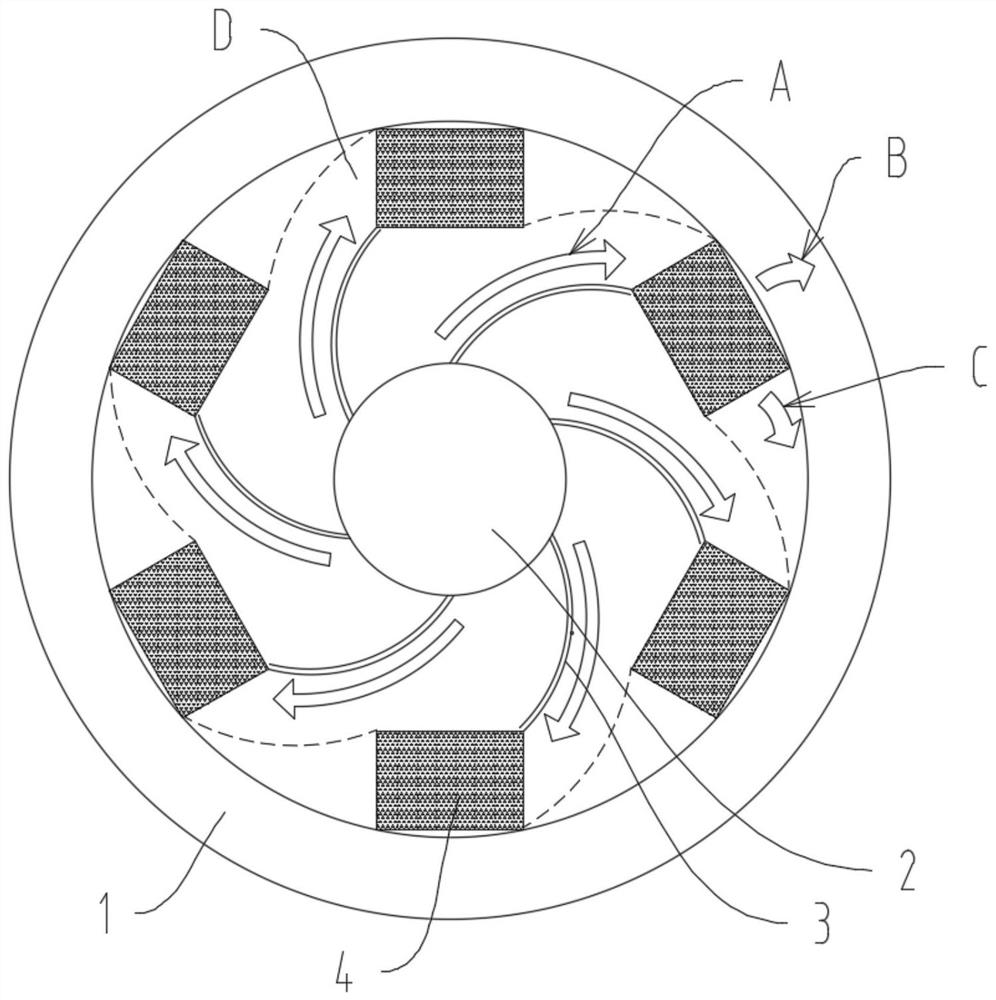

[0030] Such as figure 1 As shown, a fluid filter includes a casing 1, and the fluid to be filtered is passed into the casing 1, wherein the fluid is a liquid, and the raw liquid of the liquid is passed into the casing 1 and separated by subsequent blades 3 and filter blocks 4. The N-level clear liquid and the N-level concentrated liquid are produced. In this embodiment, the clear liquid becomes the first liquid, and the concentrated liquid becomes the second liquid.

[0031] It also includes a rotating impeller. The rotating shaft 2 of the rotating impeller is directly driven by a high-power synchronous motor (not shown). Several blades 3 of the rotating impeller drive the fluid to rotate and make the fluid generate centrifugal force. At this time, the fluid that generates centrifugal force includes not only the raw liquid, The first liquid and the second liquid are also included to ensure that the raw liquid, the first liquid and the second liquid all have power to rotate.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com