Advanced pre-supporting construction method for tunnel

A construction method and pre-support technology, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of face collapse and low stability of the face, and achieve the effect of improving stability and reducing the risk of collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

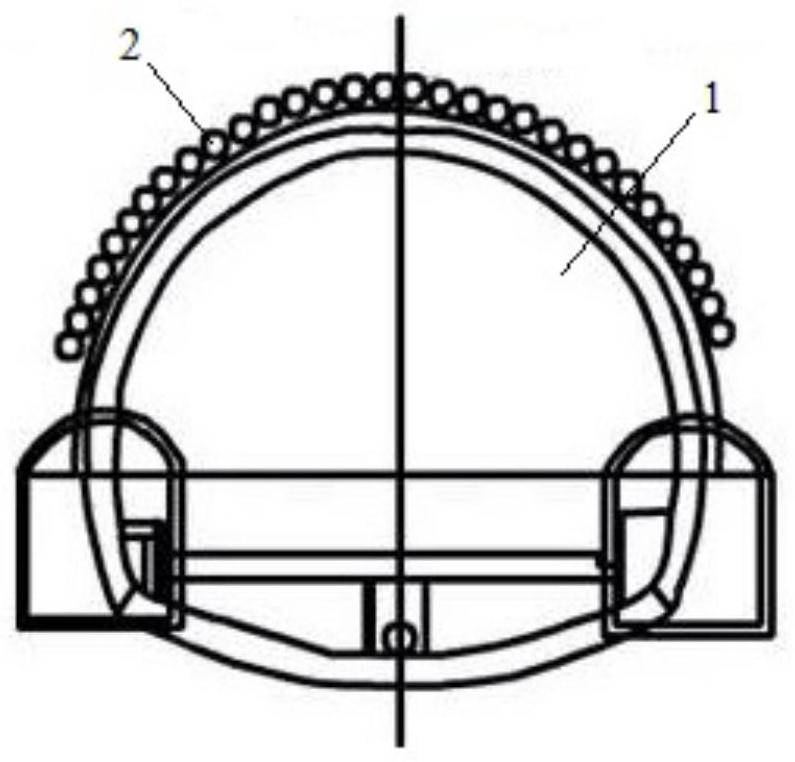

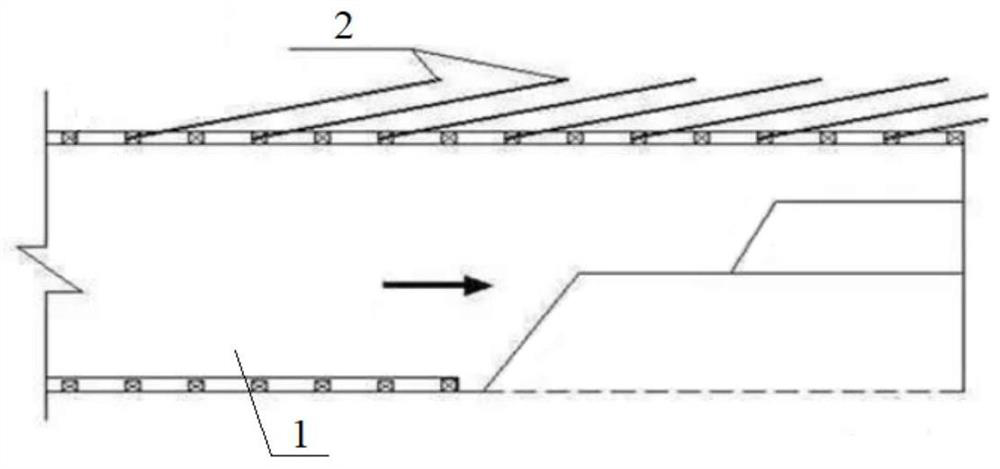

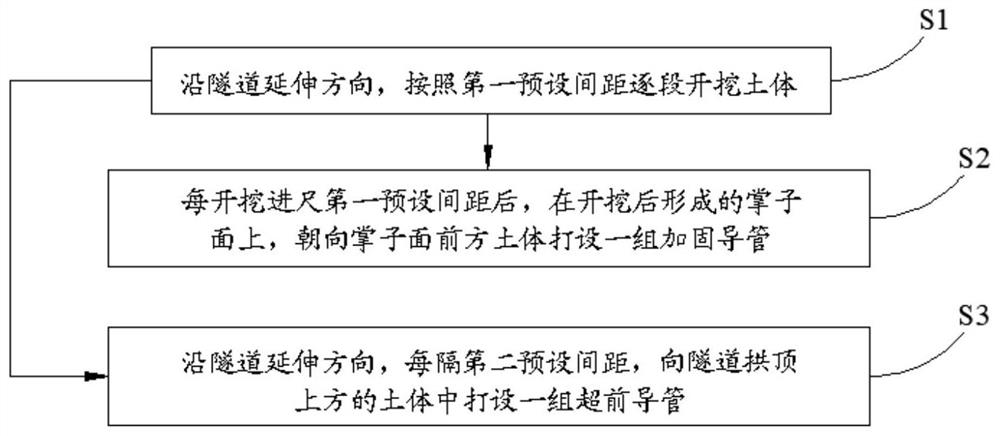

[0059] Such as image 3 As shown, the tunnel advance pre-support construction method provided in this embodiment includes the steps of excavating the soil mass, reinforcing the tunnel face and reinforcing the soil mass. The step of excavating the soil mass is denoted as S1 and the step of reinforcing the tunnel face is denoted as S2, record the soil reinforcement step as S3.

[0060] Step S1: Excavating the soil body section by section along the extension direction of the tunnel 1 according to the first preset interval;

[0061] Step S2: After the first preset distance of each excavation footage, a set of reinforcement conduits are drilled towards the soil in front of the tunnel face on the digging face formed after excavation;

[0062] Step S3: Along the extension direction of the tunnel 1, a group of advanced conduits 2 are drilled into the soil above the vault of the tunnel 1 at every second preset distance.

[0063] Wherein, there is no distinction between step S2 and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com