Cylindrical core direct shear testing machine

A testing machine and core technology, which is applied in the direction of applying stable shear force to test the strength of materials, instruments, measuring devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment, the present invention is further described as follows:

[0028] The "upper" and "lower" of the orientations indicated in this manual are marked with figure 1 as shown.

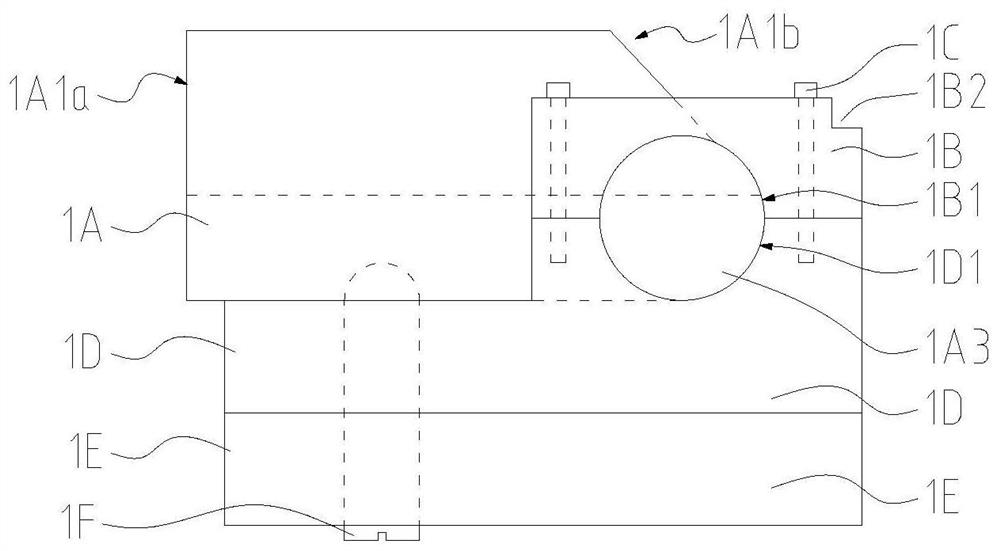

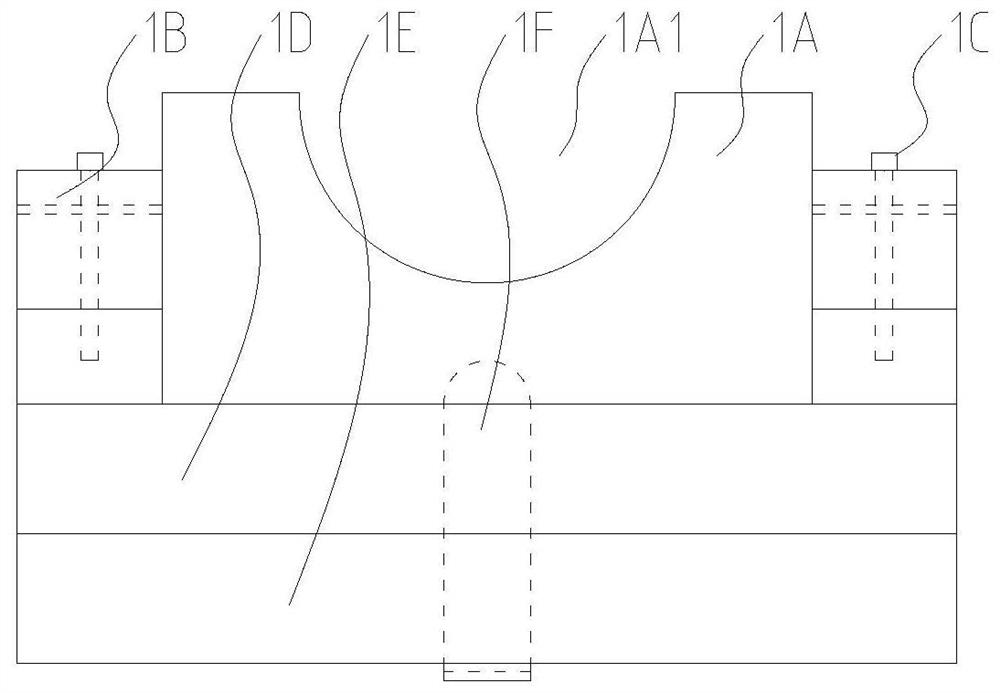

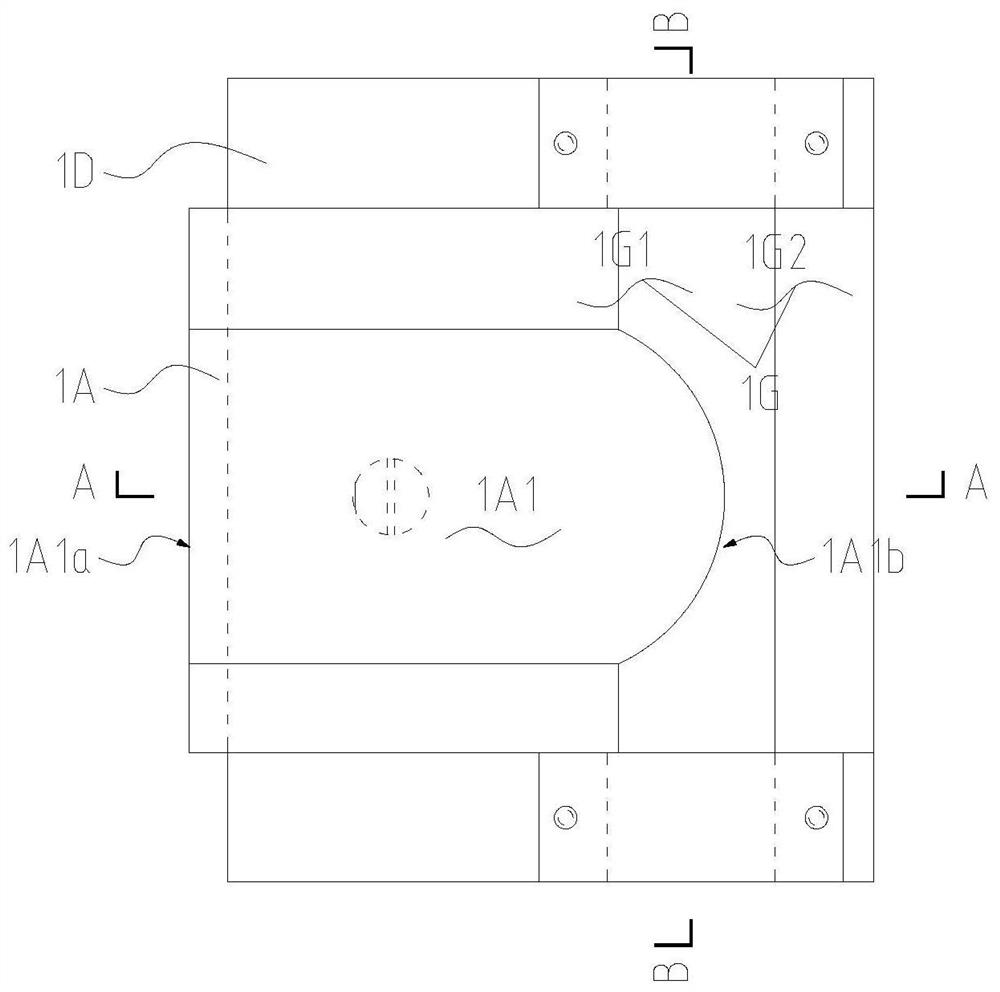

[0029] Cylindrical core direct shear testing machine, such as figure 1 , figure 2 and image 3 ,or Figure 4 and Image 6 As shown, including sample holder (1A), upper fixing plate (1B), lower fixing plate (1D) and adjusting screw (1F);

[0030] The sample holder (1A) is provided with an arc-shaped sample installation groove (1A1) with an upward opening, and the sample installation groove (1A1) penetrates from one end of the sample holder (1A) to the other. one end;

[0031] An upper fixing plate (1B) is installed on both sides of the lower fixing plate (1D) respectively, and is surrounded by the lower fixing plate (1D) and the upper fixing plate (1B) on both sides of the lower fixing plate (1D) to form a clamping area (1G) ), the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com