Roadbed compactness test detection equipment

A technology for testing equipment and compactness, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve problems such as inaccurate test results, incomplete drying, and affecting construction quality, so as to achieve fast drying speed and improve detection accuracy , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

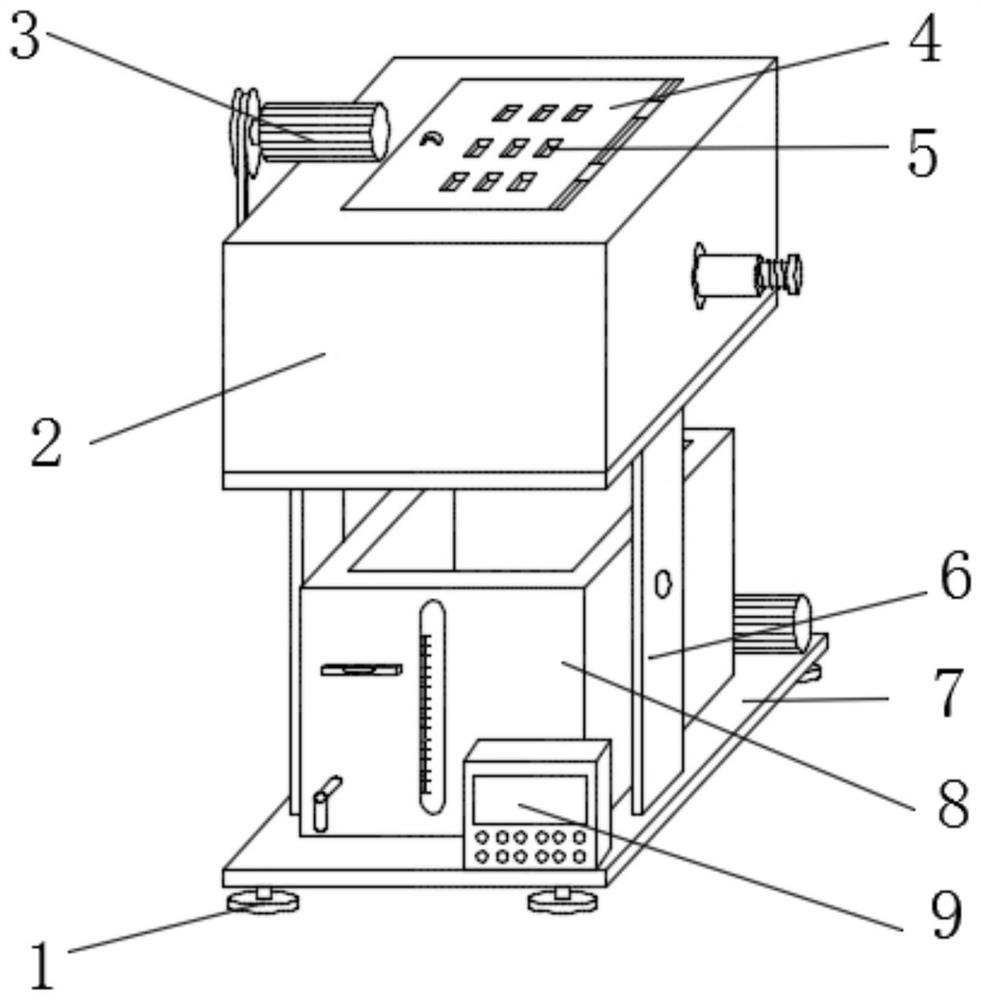

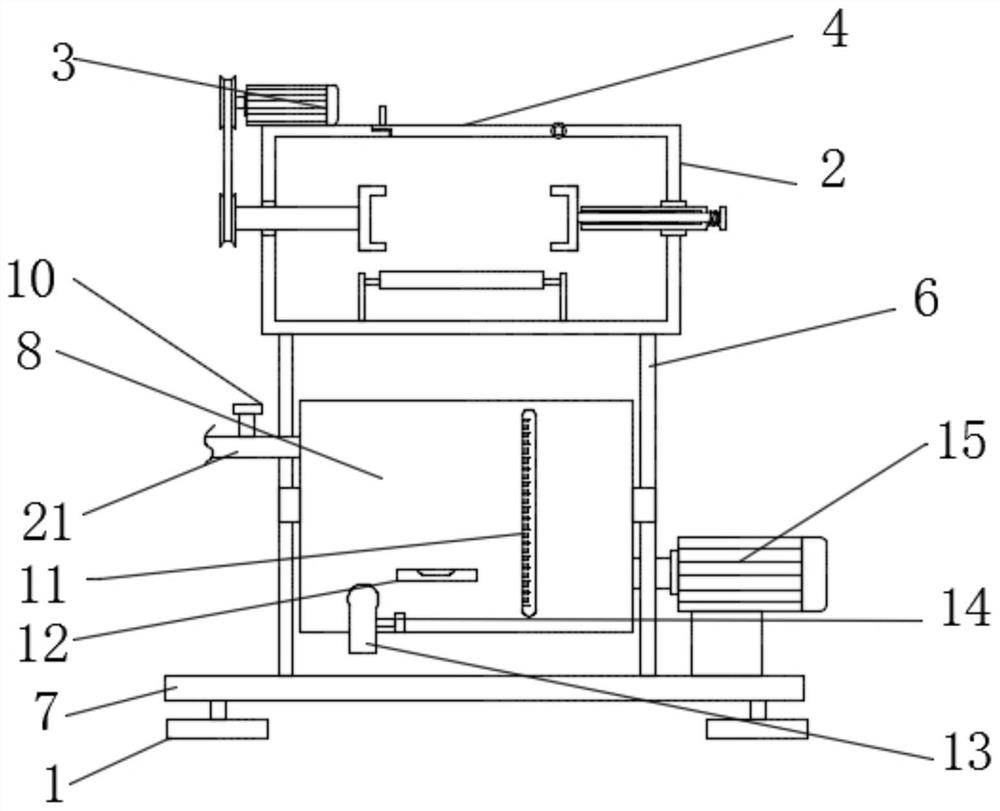

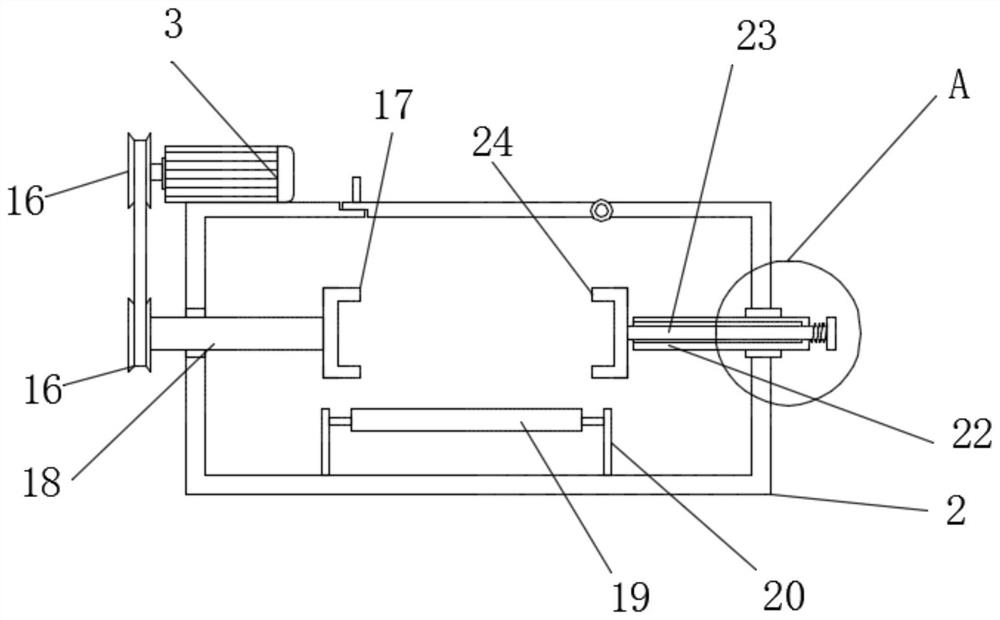

[0024] see Figure 1 to Figure 5 , a kind of subgrade compactness test detection equipment provided by the present embodiment comprises a weighing device, a water immersion tank 8 and a baking oven 2, the weighing device is provided with a support frame, and the support frame is provided with a water immersion tank and a baking oven, There is a clamp in the oven, which clamps and fixes the roadbed sample to be tested. There is a heater in the oven. The heater provides the drying heat of the oven to dry the surface of the clamp. The subgrade samples to be tested; the immersion tank is used for water immersion of the subgrade samples to be tested; the weighing device is used to weigh the subgrade samples to be tested, including the subgrade samples to be tested that are basically weighed and dried Weigh and weigh the subgrade samples to be tested after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com