Electrified detection robot for GIS equipment of super (extra) high-voltage transformer substation

A technology of live detection and substation, which is applied to the parts of electrical measuring instruments, instruments, measuring electricity, etc. It can solve the problems of falling and breaking the robot, the danger of removing the robot, and the loss of the company, so as to reduce the probability of breaking, Avoid the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

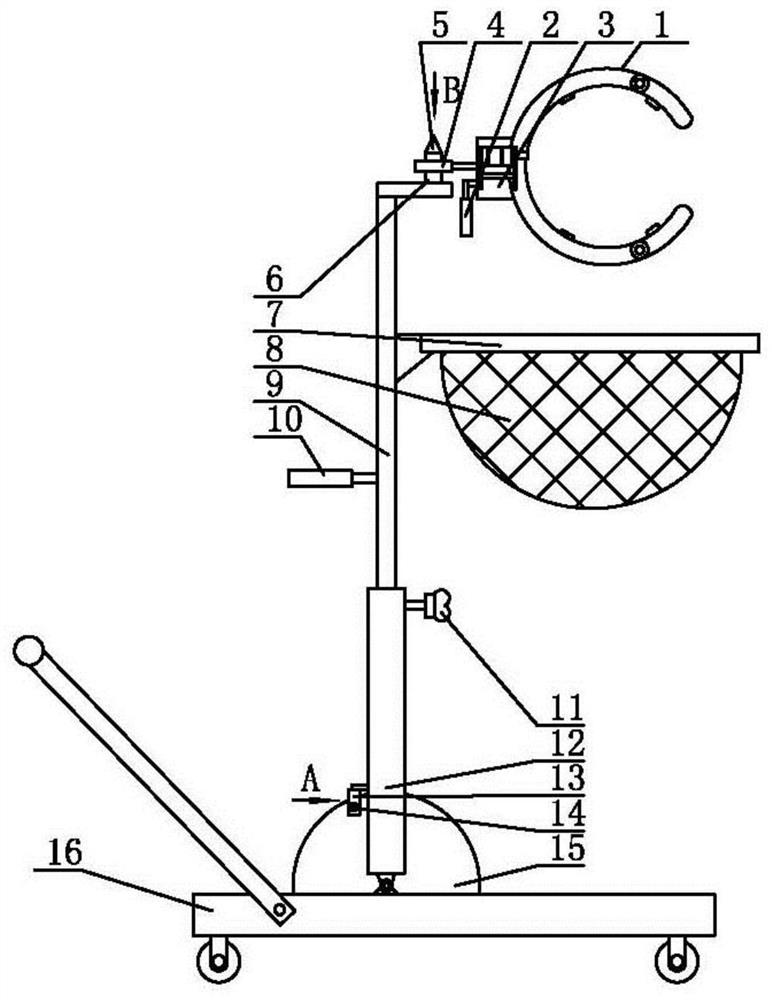

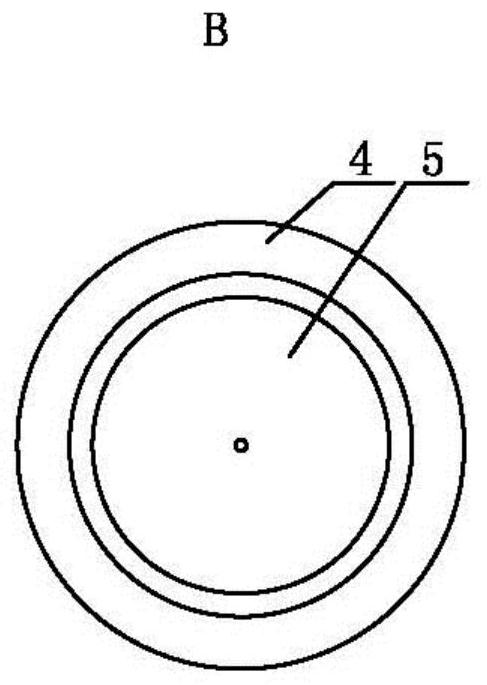

[0021] Super (Ultra) high voltage substation GIS equipment live detection robot, such as Figure 1-Figure 4 As shown, it includes a substation GIS equipment live detection robot 1 and a cart 16. One side of the substation GIS equipment live detection robot 1 has a control box 3, and the outside of the control box 3 is connected to the second fixed ring 4. The upper part of the cart 16 is The lifting device is installed, the fixed end of the lifting device is matched with the cart 16, the lifting end of the lifting device is connected to the insertion rod 6, the upper end of the insertion rod 6 is connected to the tip 5, and the tip 5 can be plugged and matched with the second fixed ring 4, Net bag 8 is installed on the lifting end side of lifting device, and net bag 8 is positioned at the below of plug-in rod 6.

[0022] The present invention can make it convenient for workers to stand on the ground to operate the lifting device without stepping on the ladder, so as to drive t...

Embodiment 2

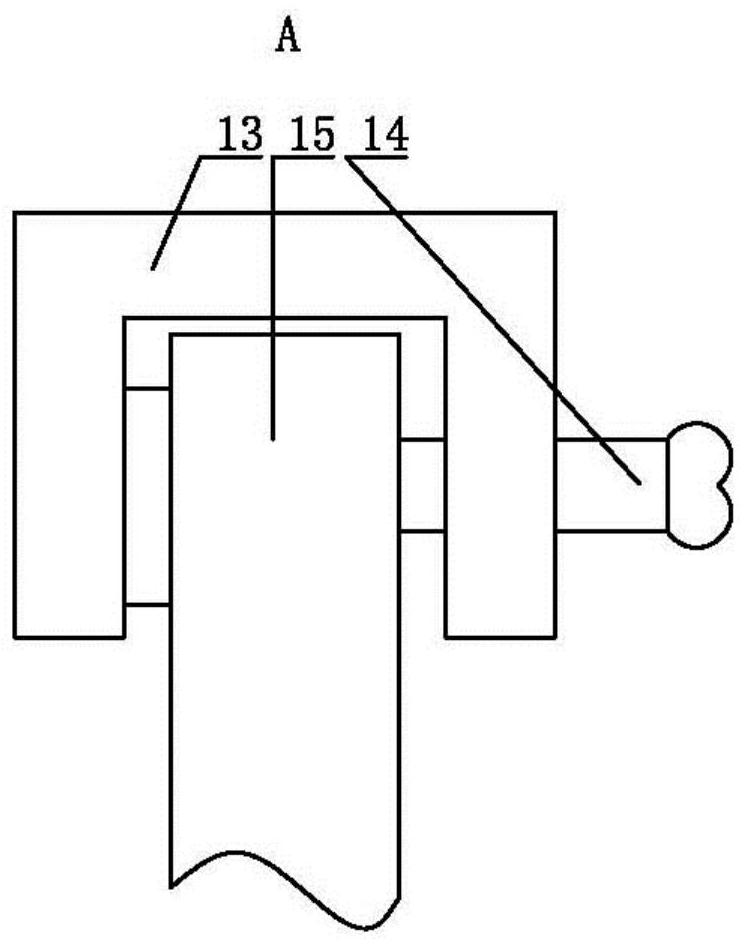

[0024] Described elevating device comprises elevating pipe 12, and elevating pipe 12 is the tubular housing of lower end sealing, and the lower end of elevating pipe 12 is the fixed end of elevating device, and the lower end of elevating pipe 12 is hinged with the top of trolley 16, and the upper end of elevating pipe 12 Insert the lifting rod 9, the lifting rod 9 is a rod-shaped structure, the lifting rod 9 can slide inside the lifting tube 12, the upper end of the lifting rod 9 is the lifting end of the lifting device, the side of the lifting tube 12 is provided with a screw hole, the lifting tube 12 Connect the first bolt 11 through the threaded hole, the screw end of the first bolt 11 can cooperate with the side of the lifting rod 9, the first bolt 11 can lock the lifting rod 9 and the lifting tube 12, the side of the lifting rod 9 Part connects net bag fixing ring 7, and the bottom of net bag fixing ring 7 is installed net bag 8, and net bag 8 is the shell structure that t...

Embodiment 3

[0027] The side of the lift rod 9 is connected with a handle 10 .

[0028] The handle 10 of the present invention can facilitate the user to push the lifting rod 9 up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com