Plate taking and threshing all-in-one machine for edible sunflowers

An all-in-one machine, sunflower-eating technology, applied in threshing equipment, harvesters, agricultural machinery and implements, etc., can solve the problems of low work efficiency, high labor intensity, large grain loss, etc., achieve simple structure, improve work efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

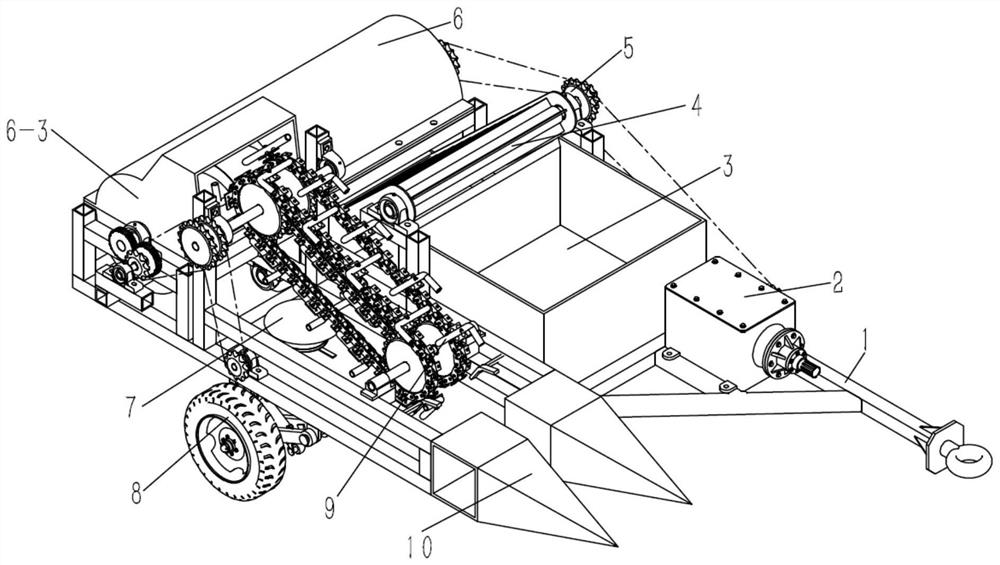

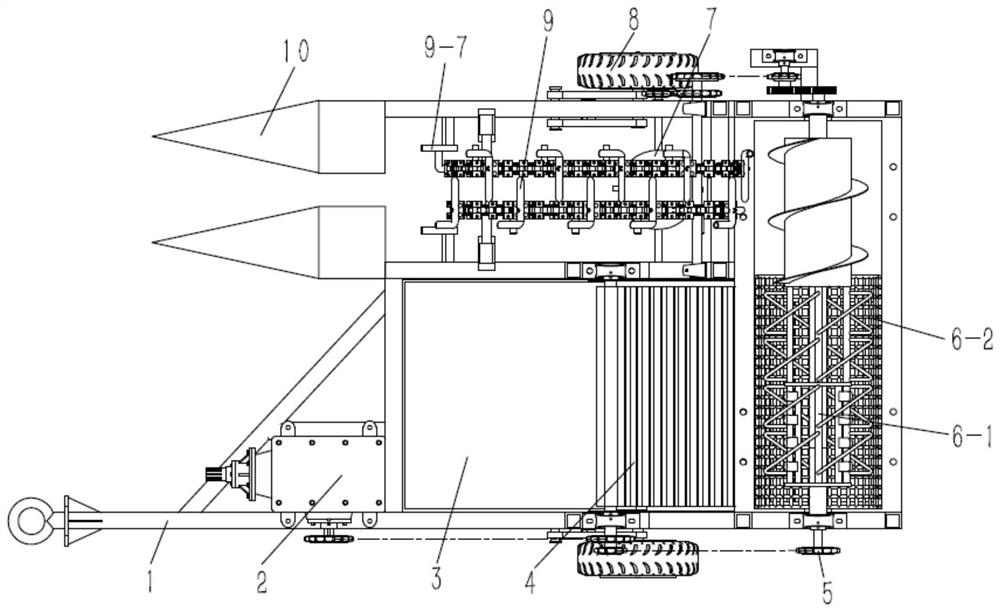

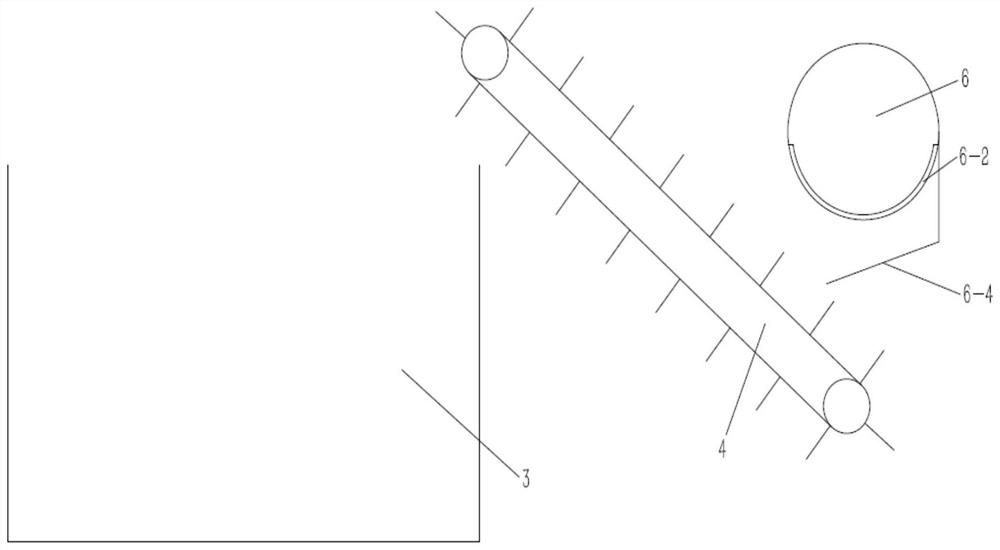

[0021] The all-in-one machine for eating sunflowers, taking pans and threshing in this embodiment is as follows: figure 1 As shown, it includes a frame 1, a grain divider 10, a gearbox 2, a disc removal device 9, a cutting rod device 7, a threshing device 6, a conveying device 4, a transmission system 5, a walking device 8, and a seed collection box 3. Its characteristics There are walking devices 8 installed on both sides of the frame 1, the grain divider 10 is installed on the right front end of the frame 1, the gearbox 2 is installed on the left front end of the frame 1, and the transmission system 5 is driven by a chain, and the seed collection box 3 is installed on the At the rear of the gearbox 2, a conveying device 4 is installed at the rear of the seed collection box 3, and the disc-taking device 9 is installed at the rear of the grain divider 10, and the cutting rod device 7 is installed under the rear end of the disc-taking device 9, and a threshing device is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com