Power Design Method for Injection Molded Parts and Its Heating Tube

An injection mold and heating tube technology, applied in the field of molds, can solve the problems of uneven heating of molding materials and difficulty in setting heating tube components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of the Power Design Method of Injection Mold Parts and Its Heating Tubes:

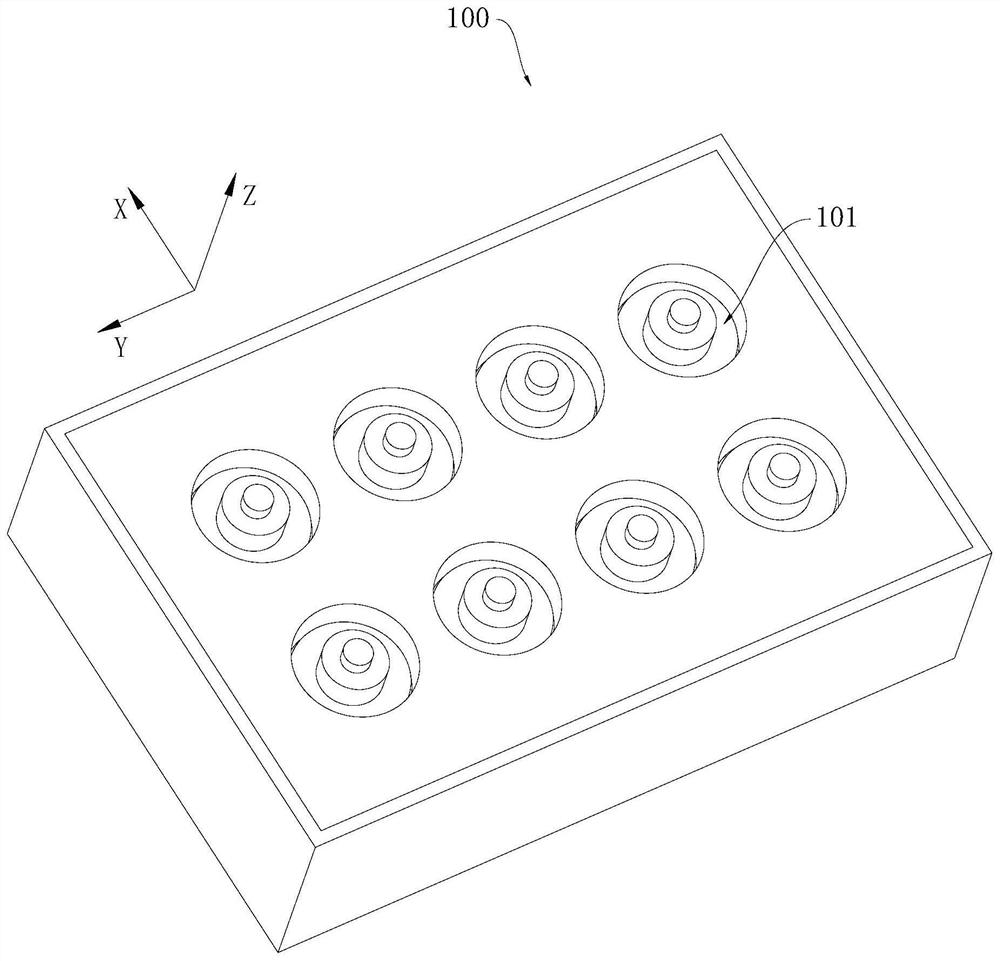

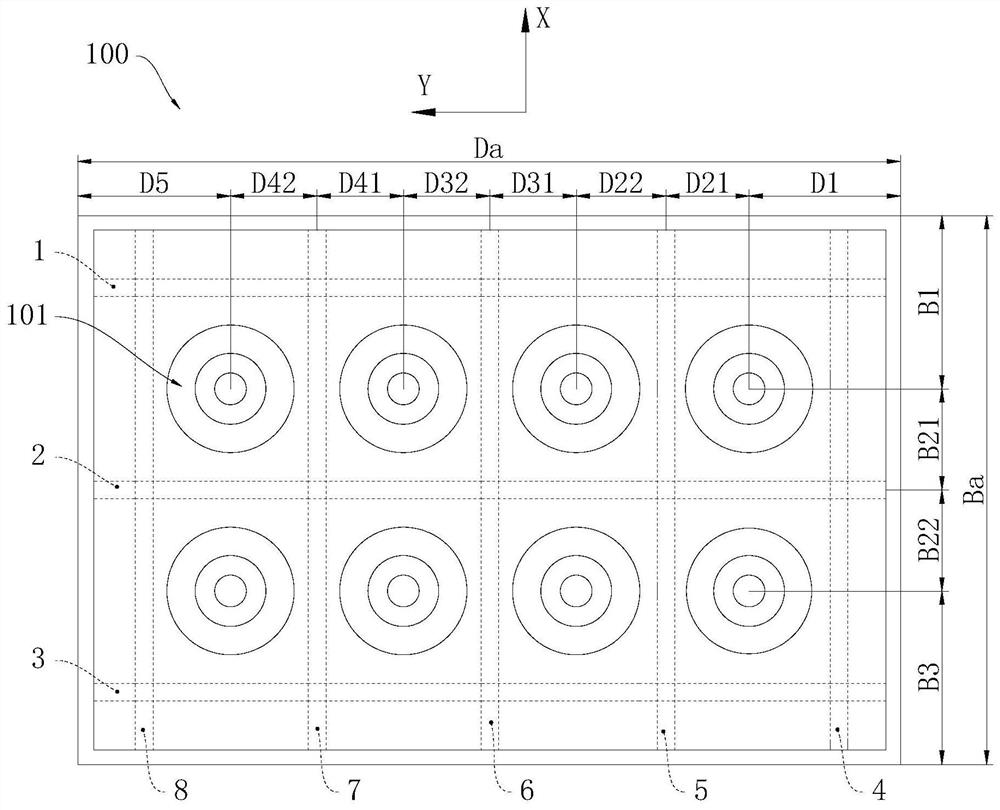

[0025] In this example figure 1 and figure 2 Using a unified space right-angle coordinate system (right hand strainer) to indicate the relative position relationship between components, where the X-axis direction is the first direction, the Y-axis direction is the second direction, the Z-axis direction is a third direction.

[0026] The injection molding member of the present embodiment is the first half die 100, and the first half die 100 is used to form an injection mold with the second semi-mold, and the first half die 100 and the second semi-mold are distributed in the Z-axis direction, the first half mode. The 100 molding cavity is surrounded between the second half, and the eight molding cavities are divided into two rows distributed in the X-axis direction, each of which has four in the Y-axis direction.

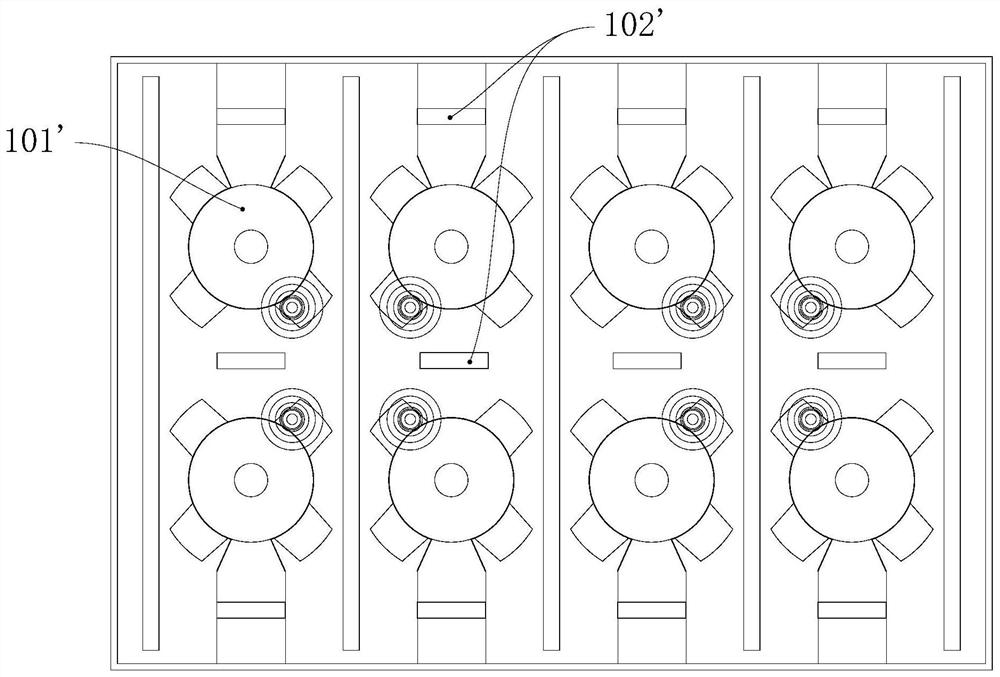

[0027] The first half die 100 is provided with eight heating tubes on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com