Driving guide mechanism of rail-road car

A road-rail dual-purpose vehicle and a guiding mechanism technology, which is applied to rail and road dual-purpose vehicles, motor vehicles, transportation and packaging, etc., can solve the problem that the traction capacity of the railway cannot be further improved, the source of driving force is single, and the power of the front rubber wheel is wasted. and other problems, to achieve the effect of shortening the railway braking distance, improving the traction capacity and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention. It is not intended to limit the present invention. The technical solution of the present invention will be described in detail below in conjunction with the embodiments and drawings, but the scope of protection is not limited thereto.

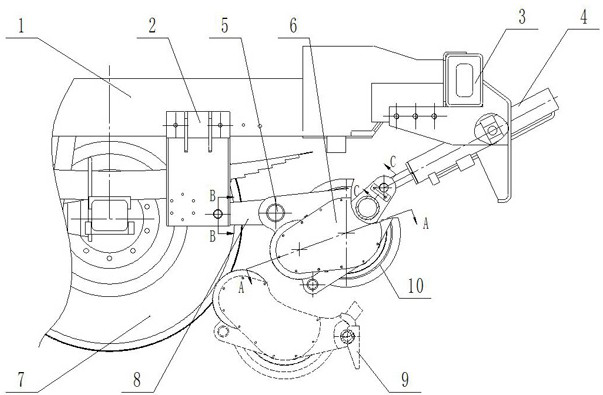

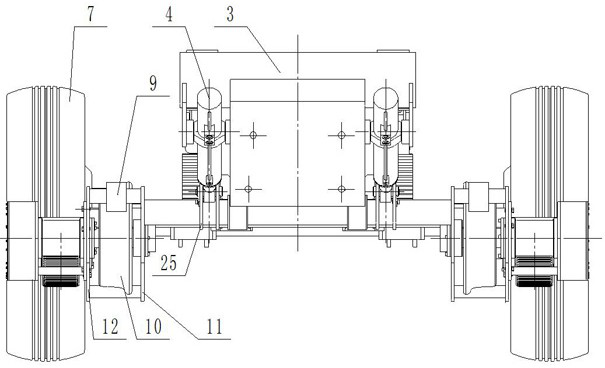

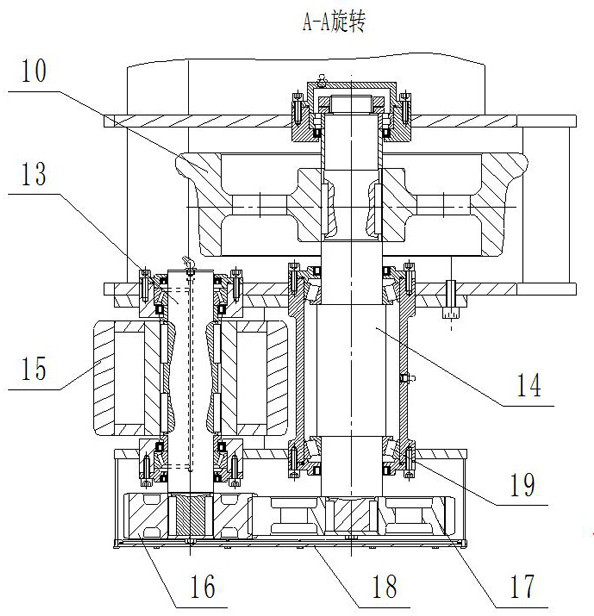

[0023] Such as Figure 1-3 As shown, the chassis longitudinal beam 1 of the road-rail vehicle is provided with a front beam 3 and a rear connecting seat 2, and the driving and guiding mechanism of the road-rail vehicle of the present invention includes a guide steel wheel 10, a rotary bracket and a guide cylinder 4 , the slewing bracket includes a connecting rod 5, a swing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com