A control method for fast belt feeding after the continuous annealing furnace is shut down

A control method and continuous unloading technology, applied in the field of control and computer control of cold rolling, can solve the problems of time-consuming and labor-intensive, and achieve the effect of ingenious technology, simple implementation, and rapidity guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

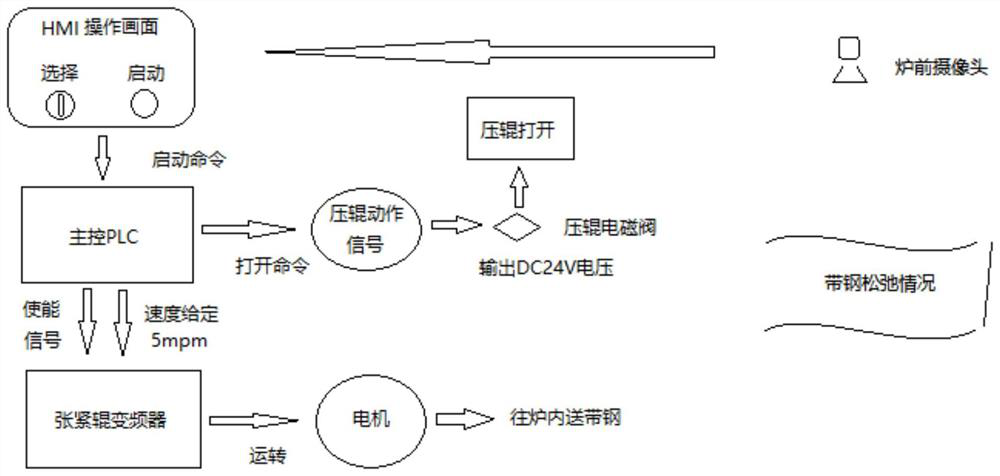

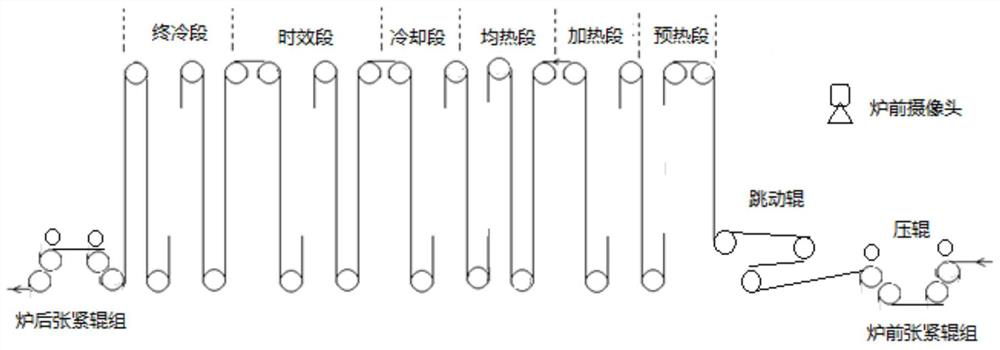

[0016] Embodiment 1: see figure 1 In this embodiment, a continuous annealing furnace with a preheating section, a heating section, a soaking section, a cooling section, an aging section, and a final cooling section is used. A dancing roll and a four-roll tensioning roll group are arranged in front of the furnace, and a four-roll sheet is arranged in the back of the furnace. Tight roller group, its process diagram is as follows image 3 shown.

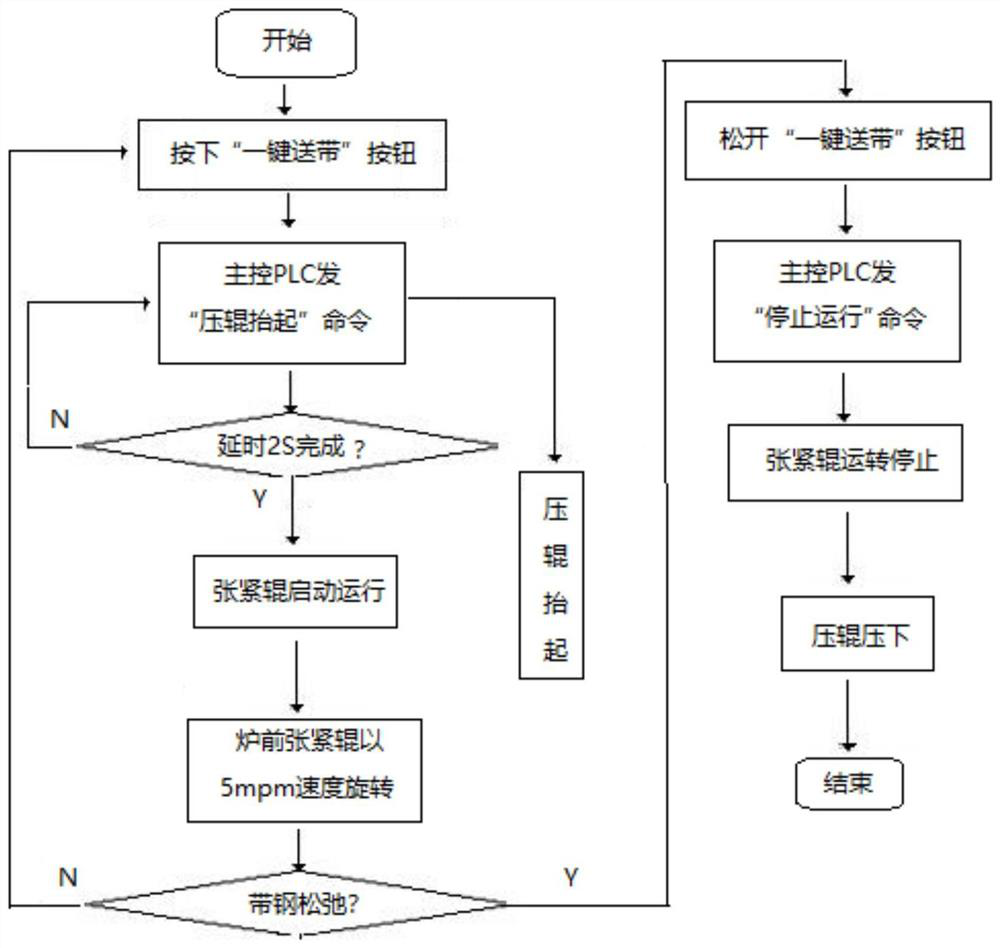

[0017] In view of the above problems, the "one-key belt feeding" scheme is adopted after the continuous annealing furnace is shut down, which can effectively prevent the problem of steel strip bending in the furnace. The control flow chart is as follows figure 2 . The implementation is as follows:

[0018] Step 1: The front of the continuous annealing furnace is equipped with a BR3 tension roller set in front of the furnace, which is used to control the tension in front of the furnace and to cut off the tension; the pressure roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com