Well cementation sliding sleeve with pressure compensation structure

A pressure compensation, sliding sleeve technology, applied in wellbore/well components, wellbore/well valve devices, sealing/packing, etc., can solve the problems of sticking, high cost, uncontrollable delay time, etc. On-time controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

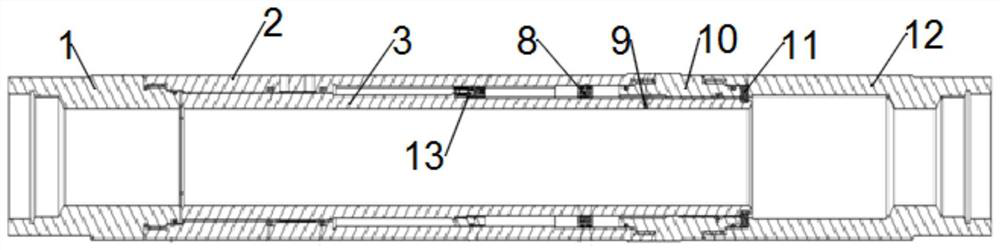

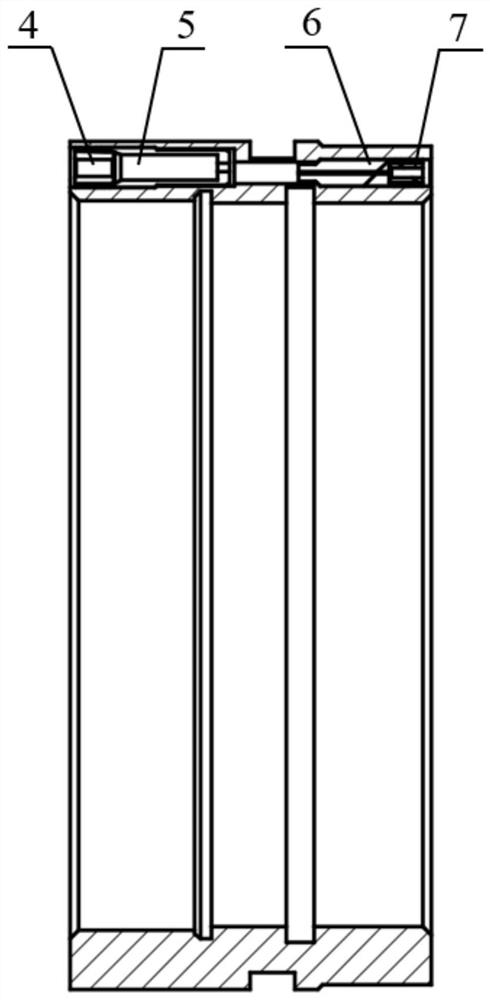

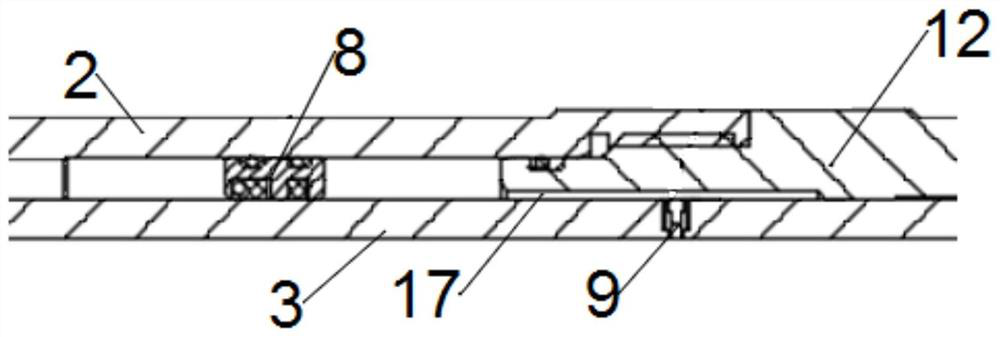

[0038] Such as Figure 1 ~ 5 As shown, the present invention has a solid well slip cover with a pressure compensation structure. The working principle of the solid ceiling sleeve of the pressure compensation mechanism is that the blasting valve 9 opens when the hydraulic pressure in the wellbore rises to the blasting valve 9 burst. The high-pressure liquid enters the slit 17 between the birds 13 and the inner slide 3 by the blasting valve 9, so that the inner skirt 3 has a pressure balance, avoiding the deep pressure of the oil and gas well, causing the slide jaw, can't start The piston set 8 separates the high pressure liquid to the original liquid in the liquid cavity, and balances the pressure of the two, and the pressure of the wellbore continues to increase in the wellbore to the high pressure liquid cavity, and after the shear ring 11 is predetermined, shear The ring 11 is cut, and then activated by a single flow valve stabilizer 4, a single flow valve 5, a current limiting v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com