A ground automatic phase separation device and its control method for partitions

A technology of automatic over-phase and zoning, applied in transportation and packaging, power lines, vehicle parts, etc., can solve the problems of high operation and maintenance costs, long switching time of mechanical switches, accelerated aging of main insulation, etc., to reduce operation and maintenance costs. , the effect of reducing the dead time of switching and preventing the circulation of the power flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Such as figure 2 As shown, the ground automatic phase separation device used in the partition of this embodiment includes a control unit 1, a detection unit connected to the control unit 1, two thyristor valve group units 2, and the two thyristor valve group units 2 are located in the neutral zone and the partition. Between the power supply arms of the substation on both sides of the substation, that is, between the neutral zone and the power supply arm on one side, and between the neutral zone and the power supply arm on the other side, a thyristor valve group unit 2 is respectively arranged, and each thyristor valve group unit 2 It includes two thyristor valves connected in anti-parallel connection, each thyristor valve is connected to the control unit 1, when the train is over-phased, the detection unit detects the network pressure signal and the current signal of the two thyristor valve group unit 2, and sends them to the control unit 1, The control unit 1 generate...

Embodiment 2

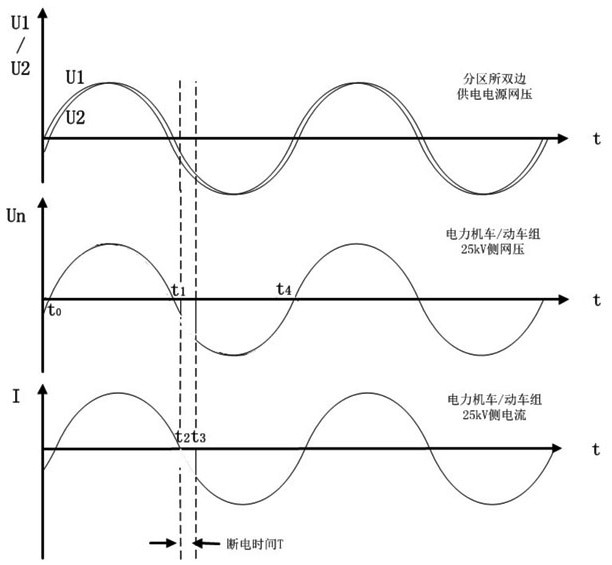

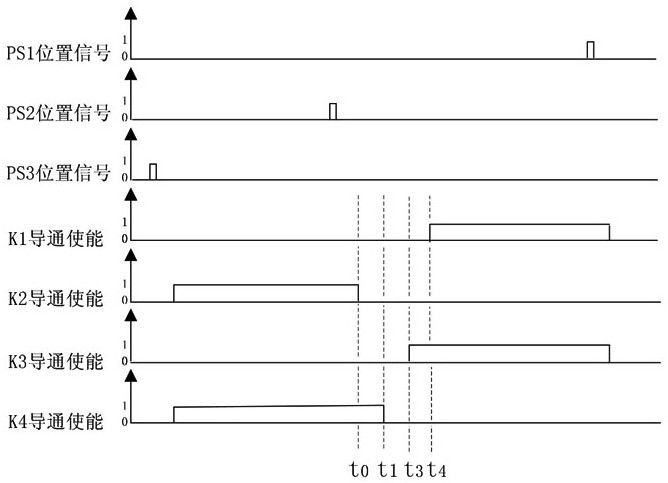

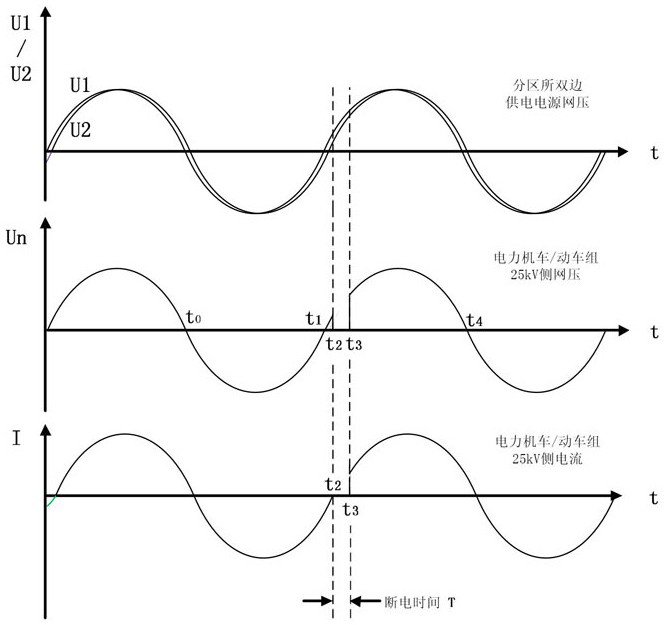

[0083] Such as Figure 5 As shown, from left to right is forward driving, and from right to left is reverse driving. The thyristor valve group unit 2 of this embodiment specifically includes a thyristor valve connected between the power supply arm of the substation on the left side of the divisional substation and the neutral zone. K1, thyristor valve K3, and thyristor valve K2, thyristor valve K4, thyristor valve K1, thyristor valve K3, thyristor valve K2, and thyristor valve K4 connected between the neutral zone and the power supply arm of the substation on the right side of the district substation are respectively connected with the control The unit 1 is connected, and the control unit 1 generates control signals and sends them to the thyristor valve K1, the thyristor valve K3, the thyristor valve K2, and the thyristor valve K4 to control on-off. By controlling the on-off of thyristor valve K1, thyristor valve K3, thyristor valve K2, and thyristor valve K4 independently thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com