Rotary locking control method of plastic injecting nozzle

A technology of injection nozzle and control method, which is applied in the field of plastic molding processing technology, can solve the problems of the degree control of nozzle channel opening, insufficient response, slow nozzle opening and closing speed, etc., and achieves the improvement of reaction speed, reduction of overheating decomposition, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

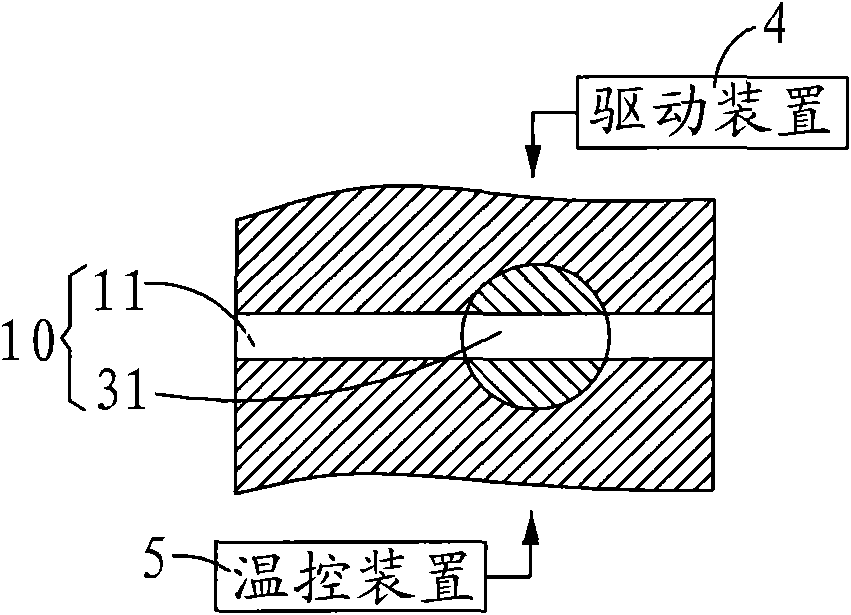

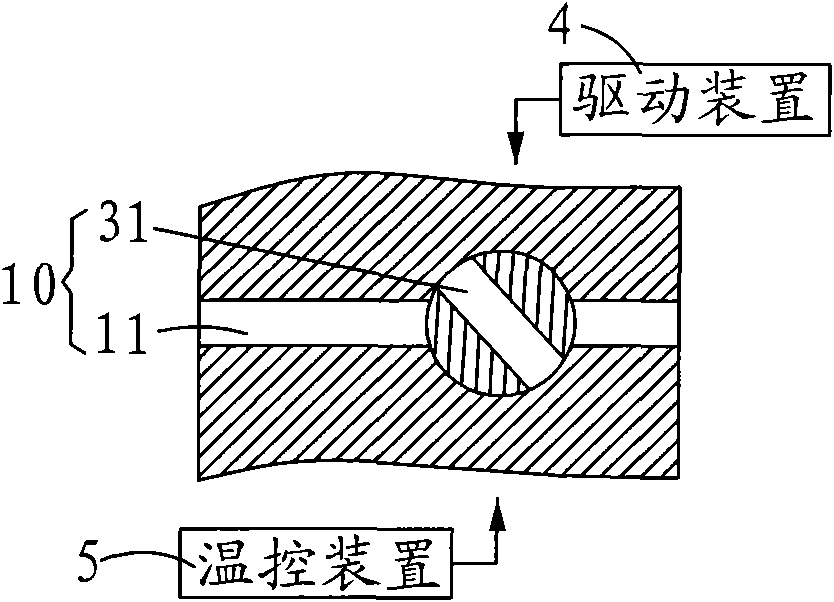

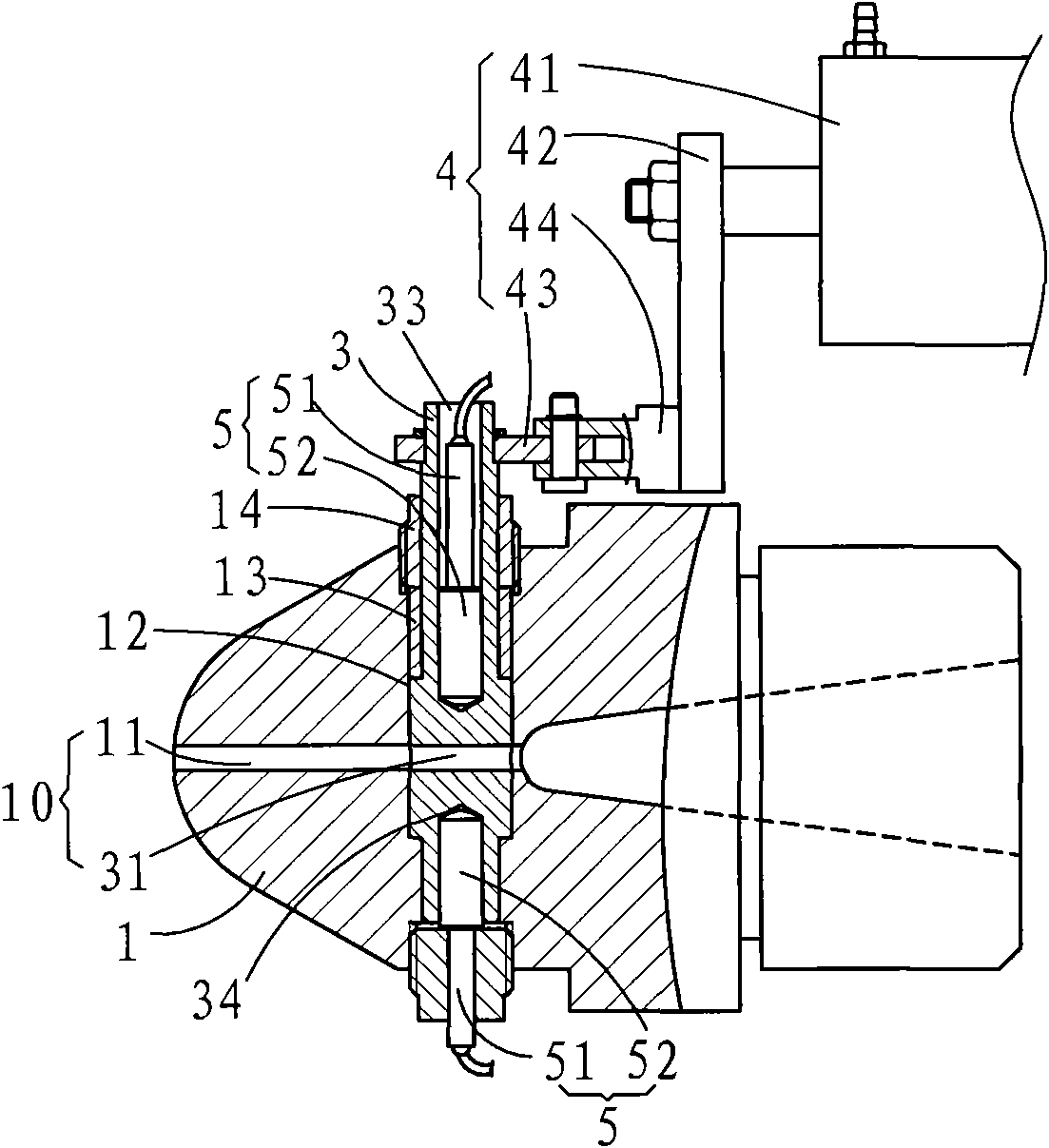

[0021] see Figure 1a with Figure 1b As shown, the rotation locking control method of the plastic injection nozzle of the present invention mainly divides the injection channel 10 of the injection nozzle into two parts: a fixed injection channel 11 and a rotating injection channel 31, and by rotating the rotation The injection channel 31 and the fixed injection channel 11 have two states of staggering each other to close the injection channel 10 and aligning with each other to open the injection channel 10 . The rotating material injection channel 31 is additionally provided with a driving device 4, and by setting the operation of the driving device 4, the start and end time, The speed of opening and closing and the degree of opening and closing. During the plastic injection process, a temperature control device 5 is used to control the temperature of the plastic melt in the plastic injection channel 10 at the same time.

[0022] see Figure 2 to Figure 4 As shown, a schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com