Task-based maintenance support equipment optimization method

An optimization method and equipment technology, applied in the field of aviation equipment support, can solve problems that affect the completion of support work, affect efficiency, and slow combat operations, and achieve the effect of improving scientificity and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

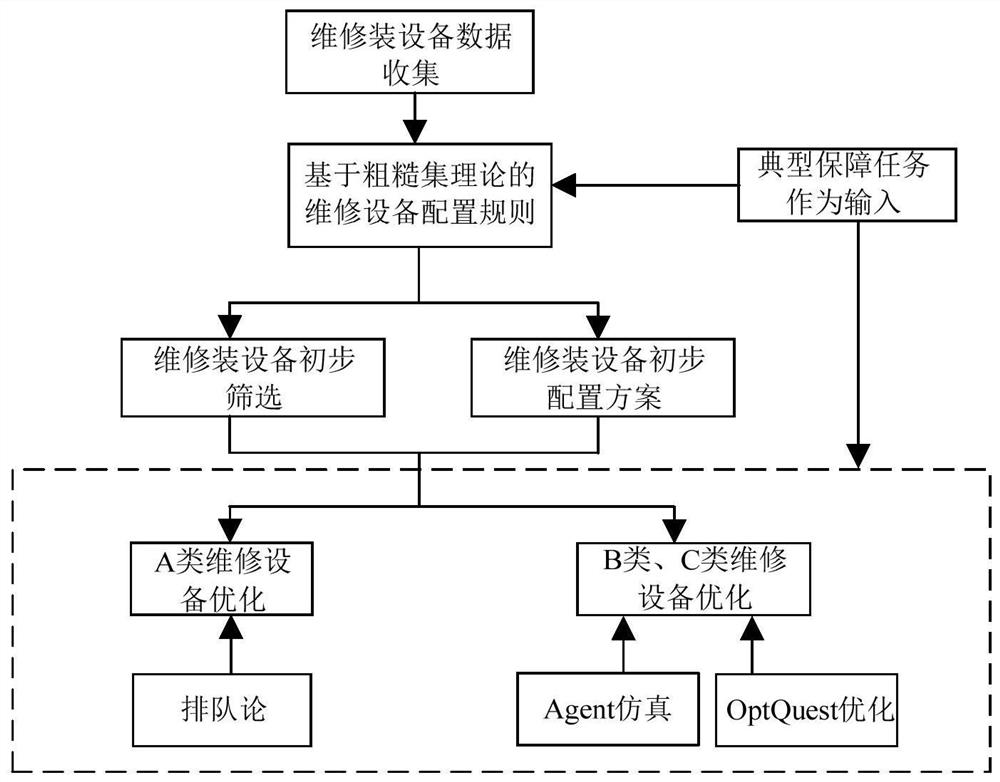

Method used

Image

Examples

Embodiment 2

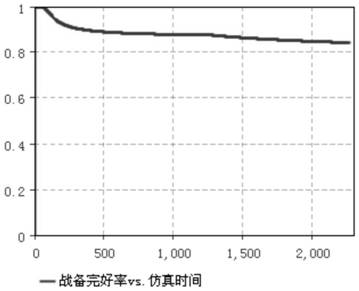

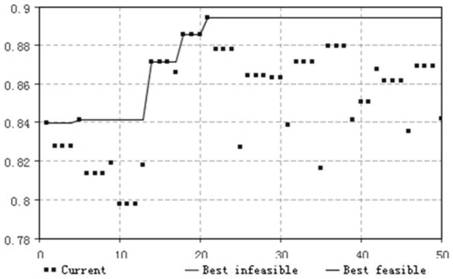

[0158] Embodiment 2 related to S3: It is assumed that under a certain typical support task condition, a fleet of 16 aircraft is required, and the average flight time of each aircraft is 4 hours per day. Assume that the key maintenance and support equipment needed to perform this typical support task is as follows: Figure 10 As shown, it shows how many maintenance and support equipment are needed to ensure the combat readiness rate of the aircraft fleet is above 89%.

[0159] Assume that the following 30 types of maintenance support equipment, that is, equipment with troubleshooting function and preventive maintenance function, are simulated, and the initial configuration quantity is shown in Table 4.1.

[0160] ⅰ. Use the allocation rules of maintenance resources established by rough set theory to design the initial value of these 30 kinds of maintenance support equipment, such as Figure 10 , for example, for No. 1001 maintenance support equipment, its configuration quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com