Multilayer self-adhesive fouling release film with textured surface

A textured, self-adhesive technology for film/flake adhesives, coatings, laminations, etc. that solves the problems of economic loss, time consuming, and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

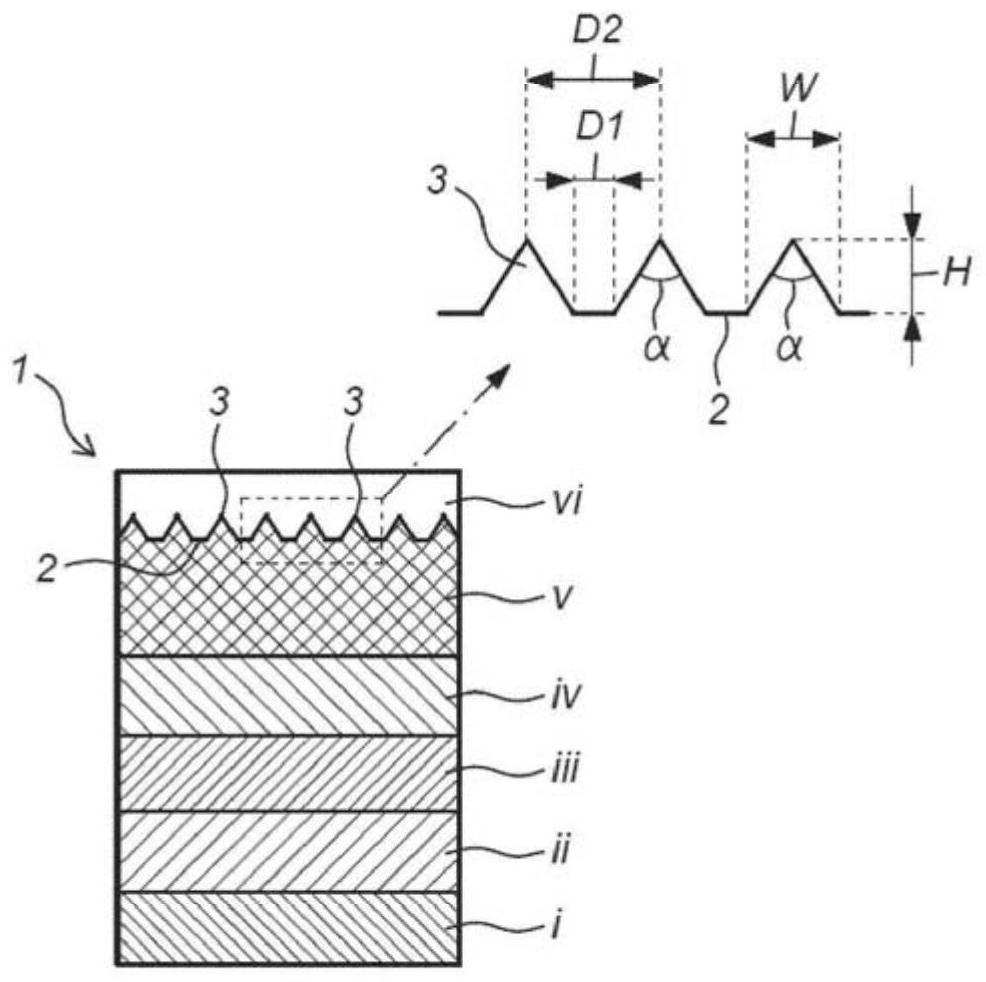

[0148] Figure 1-5 and 8 show a preferred embodiment of the multilayer self-adhesive soil release film with a textured surface of the first aspect of the invention, and a preferred embodiment of the method of the second aspect of the invention in producing said textured surface use in the film.

[0149] figure 1 An example of a multilayer self-adhesive soil release film 1 with a textured surface is shown, comprising:

[0150] (i) Removable lower liner;

[0151] (ii) an adhesive layer applied to and overlying the underlying liner i;

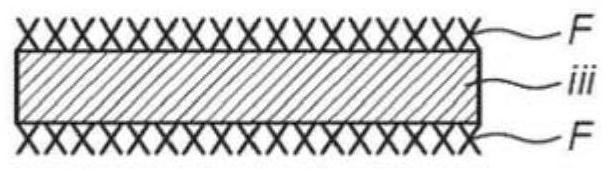

[0152] (iii) a layer of synthetic material applied to and overlying the layer of adhesive ii;

[0153] (iv) an intermediate silicone tie layer applied to and overlying the synthetic material layer iii and being a one-component silicone system, a two-component silicone system or a three-component silicone system;

[0154] (v) a silicone soil release topcoat applied to and overlying the intermediate silicone tie layer iv and comprising a silic...

Embodiment 8

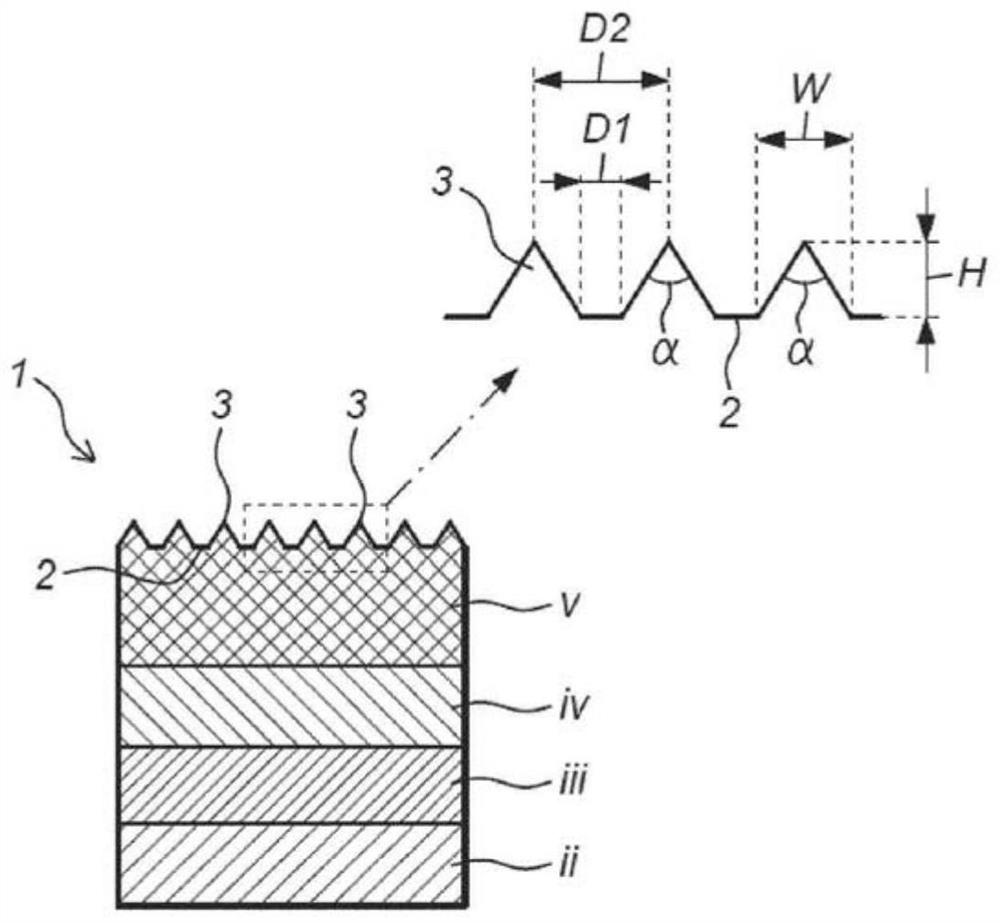

[0171] 4. A fouling release membrane 1 with a textured surface according to an embodiment of the present invention ( image 3 ) (Example 8); and

[0172] 5. Pyramid shaped foul release foil (i.e. a film 1 with a textured surface according to an embodiment of the invention, and as image 3 shown, when applied to the test body, except Figure 7 except for the different surface morphologies shown) (Example 9).

[0173] After filling the tunnel with water and carefully degassing it, while measuring the total resistance acting on the test body, increase the water velocity in 10 steps to 10m / s, then decrease it in intermediate steps to zero speed. The whole process of increasing and decreasing the water speed lasted 2 hours. Average the measured data during each speed step.

[0174] A detailed analysis of the measured data yielded the relative frictional resistance of the different samples compared to a standard fouling release spray coating. The smooth foil (Example 7) exhibi...

Embodiment 10-12

[0176] 1. A smooth dirt release foil (i.e., with the exception of the absence of ribs 3 in surface image 3 Films with textured surfaces shown are the same) (Example 10);

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com