Cement mortar additive comprising hydrophobic silica, and preparation method therefor

A technology for cement mortars, manufacturing methods with applications in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

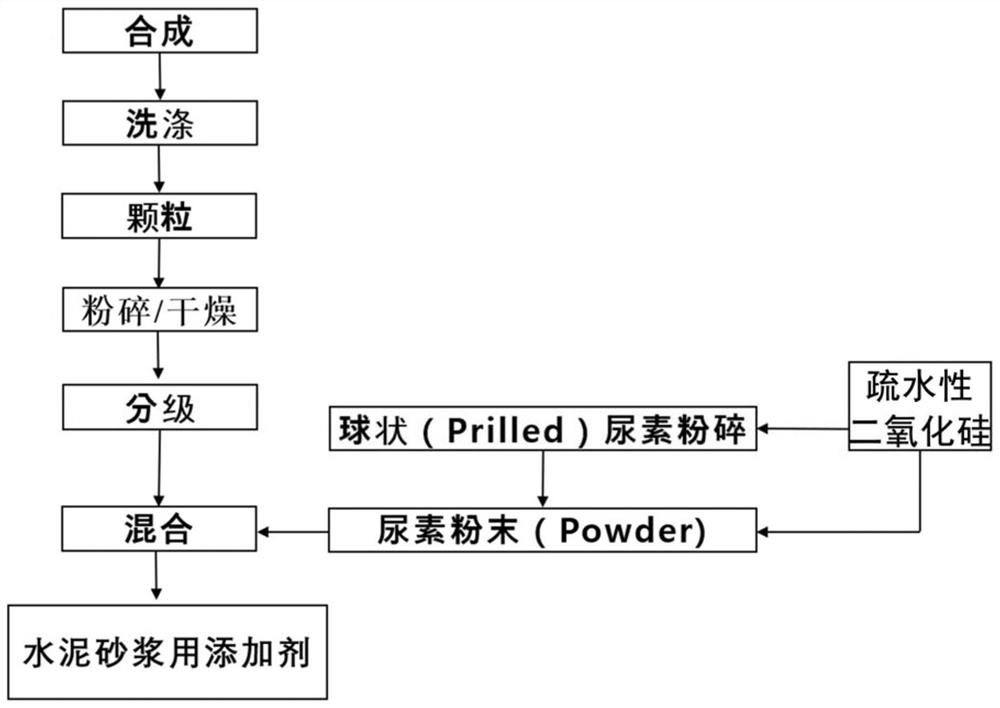

Method used

Image

Examples

Embodiment 1

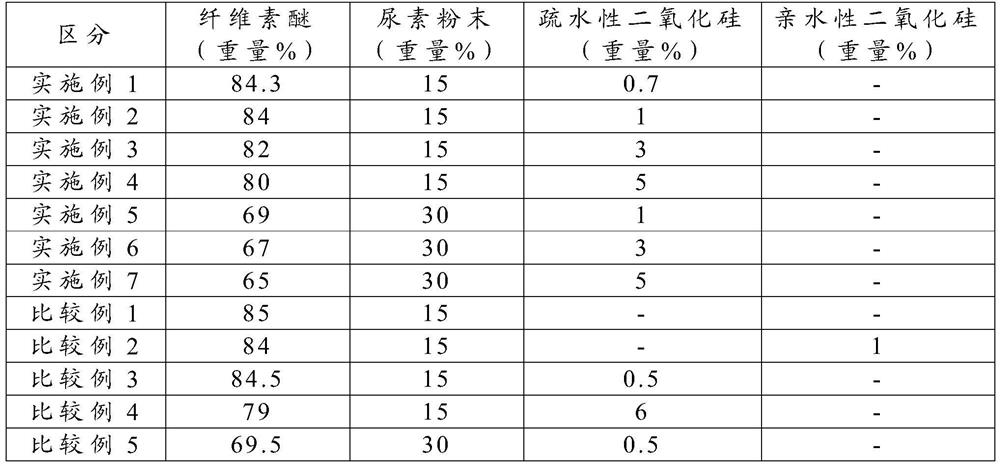

[0053] Utilize top pulverizer to pulverize urea (spherical type (prill type), Mitsui Chemicals, Inc.) to the average particle size of 85 μ m, then according to the content in Table 1, mix hydrophobic type silica [mean Particle size: 7μm, Sipernat D17, Evonik Industries, specific surface area (ISO 5797-1) 110m 2 / g] and hydroxyethyl methylcellulose [HEMC, average particle size: 85 μm, 60,000 cps (Brookfield HA, 20rpm, 2.0%, 20°C), DS1.5, MS0.3, Lotte Fine Chemicals], thereby manufacturing Additives for cement mortar.

Embodiment 2 to Embodiment 4 and comparative example 1 to comparative example 4

[0055] The additive for cement mortar was manufactured by the same method as Example 1, and the additive for cement mortar was manufactured by mixing according to the content in Table 1.

[0056] In Comparative Example 2, hydrophilic silica (Sipernat 622S, Evonik Industries) was used instead of hydrophobic silica.

Embodiment 5 to Embodiment 7 and comparative example 5

[0058] Except that on the basis of the method of Example 1, the method of pulverizing urea in a state of being put in together with hydrophobic silica is used instead of pulverizing urea alone, the same method is used to manufacture additives for cement mortar, wherein according to Table 1 Content mixed manufacturing.

[0059] [Table 1]

[0060]

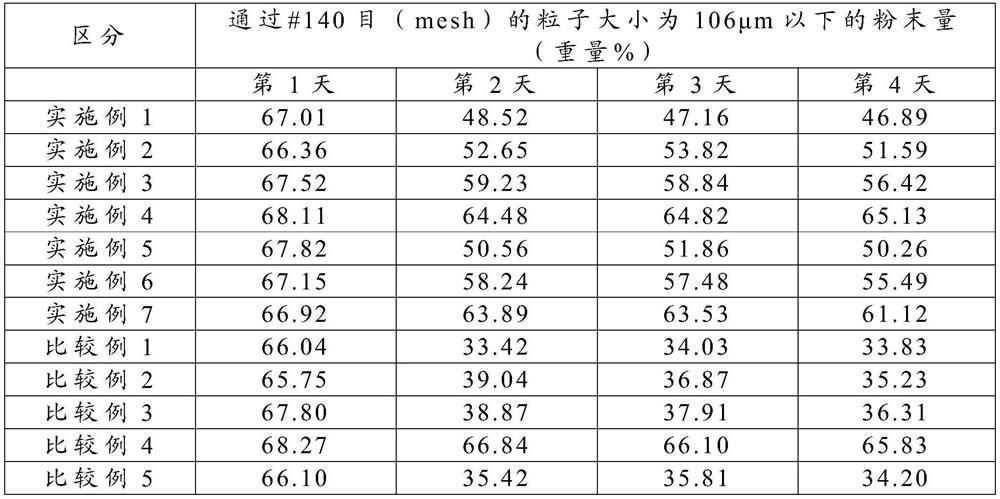

[0061] [Characteristic evaluation]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com