Dispensing method for display screen device with frameless fourth edge

A borderless, display technology, applied to devices that apply liquid to the surface, pre-treatment surfaces, coatings, etc., can solve the problems of low dispensing efficiency, small effective use area of the screen, and long duration of the dispensing process. , to improve the efficiency of dispensing, improve the utilization rate, and the effect of aesthetic utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

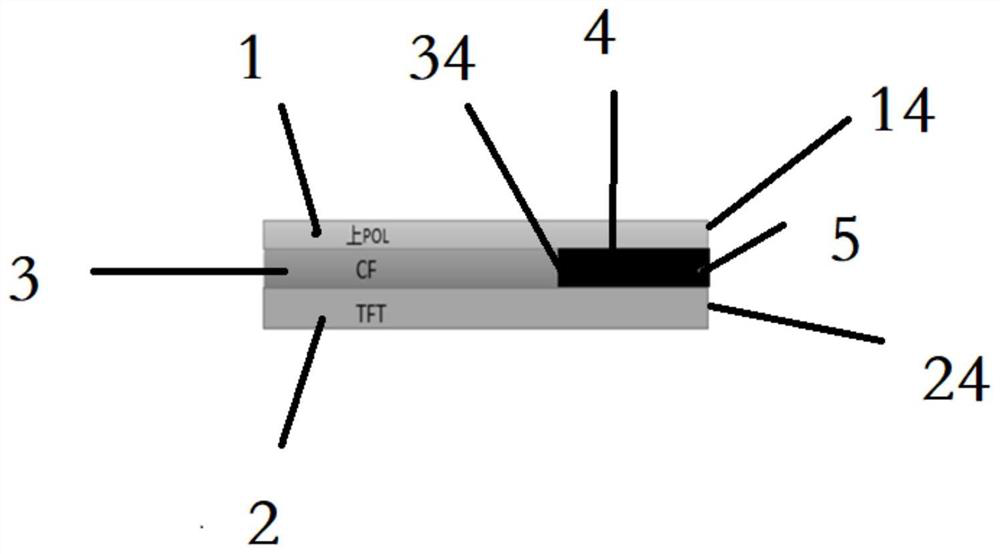

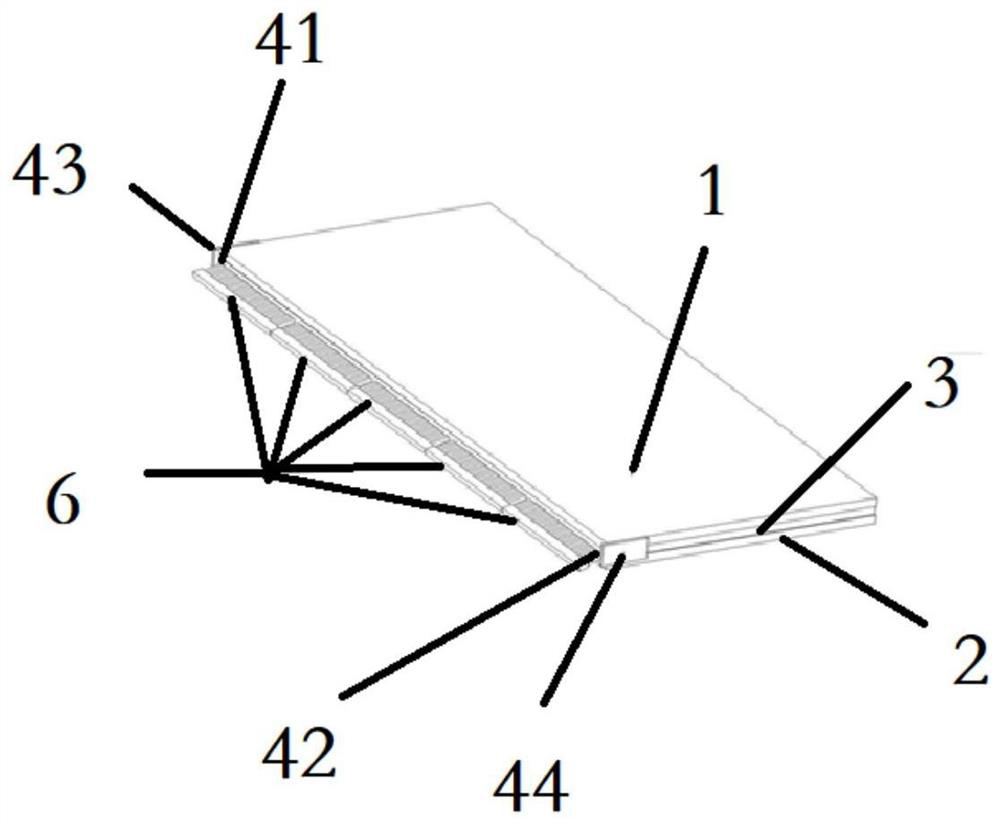

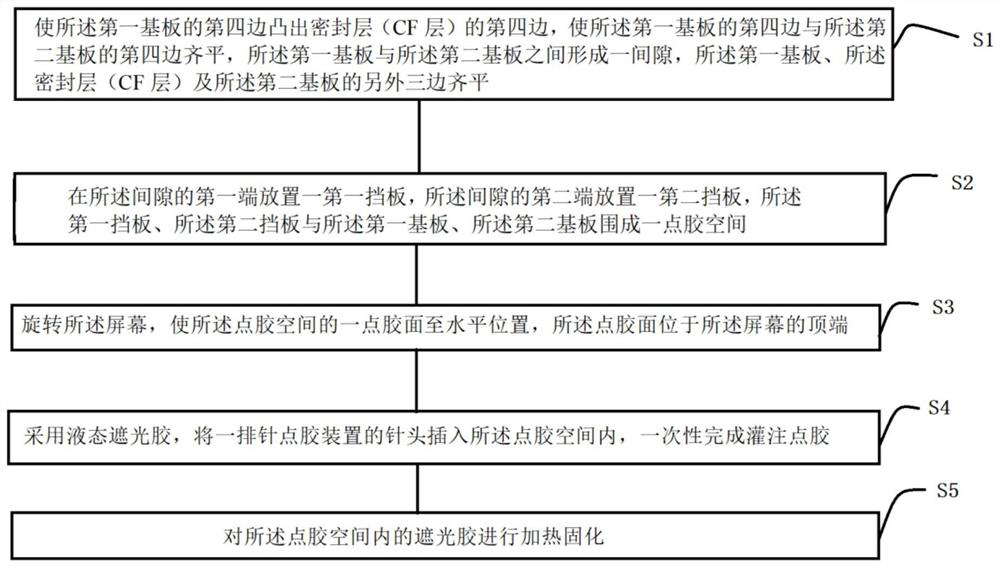

[0051] refer to figure 1 and image 3 As shown, the specific embodiments will be described below. For the borderless dispensing device on the fourth side of the large-size screen, the length of the dispensing frame is 200mm, and the distance between the first substrate and the second substrate on both sides of the sealing layer The width between them is 0.5mm, that is, the thickness of the sealing layer is 0.5mm, and the distance between the fourth side of the sealing layer and the fourth side of the first substrate and the second substrate is 1.5mm-2mm.

[0052] The length of the dispensing needle of the dispensing device is greater than or equal to the height of the dispensing space. The dispensing needle is a cylindrical needle. Pull in the direction of the four sides, and in the process of pulling the needle dispensing device, the needle dispensing device is always dispensing glue, which can realize dispensing at one time, and avoid low efficiency and coating caused by mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com