Goaf water inrush and grouting treatment comprehensive test device and method

A technology for water inrush and comprehensive test in goaf is applied in the field of comprehensive test device for water inrush and grouting treatment in goaf, which can solve the problem of single simulation situation, inability to detect treatment effect, and lack of disaster-causing mechanism to systematically study grouting treatment Research and other issues to improve the systemic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

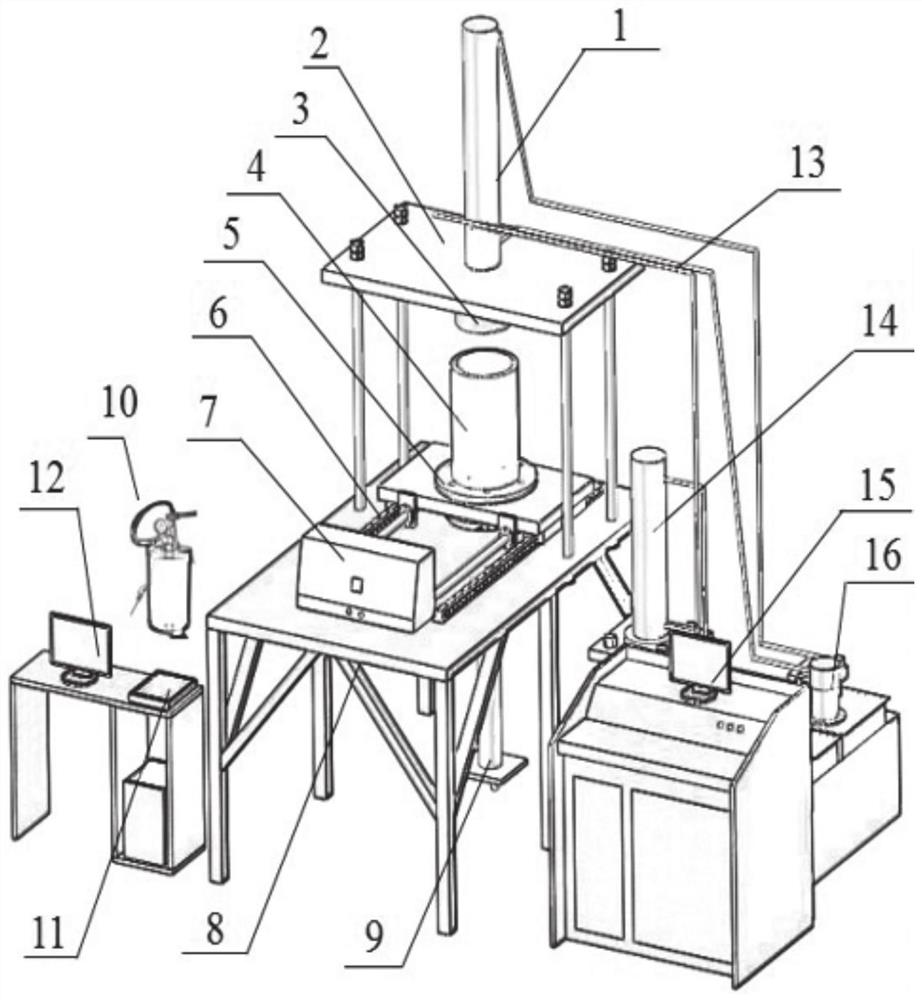

[0040] In a typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a comprehensive test device for goaf water inrush and grouting treatment is provided.

[0041] Including the test bench as the overall frame, the test cavity module and the monitoring mechanism of the test core components, wherein the test cavity module includes a loading mechanism and a grouting mechanism, and the loading mechanism is installed on the test bench;

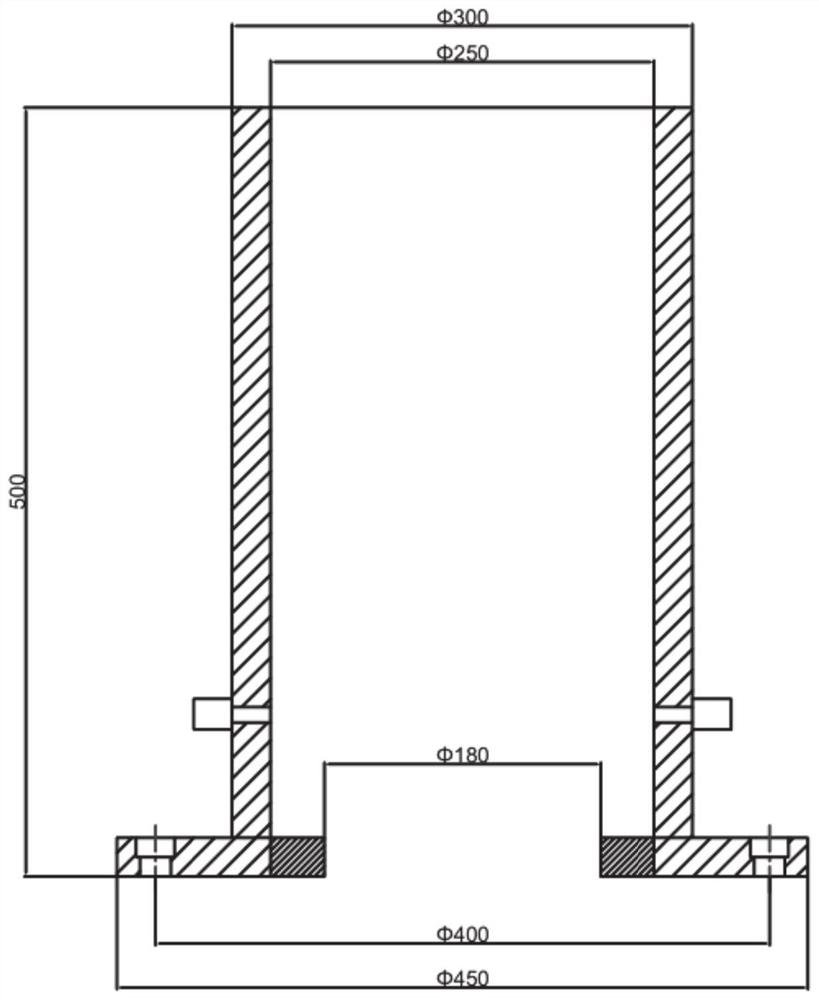

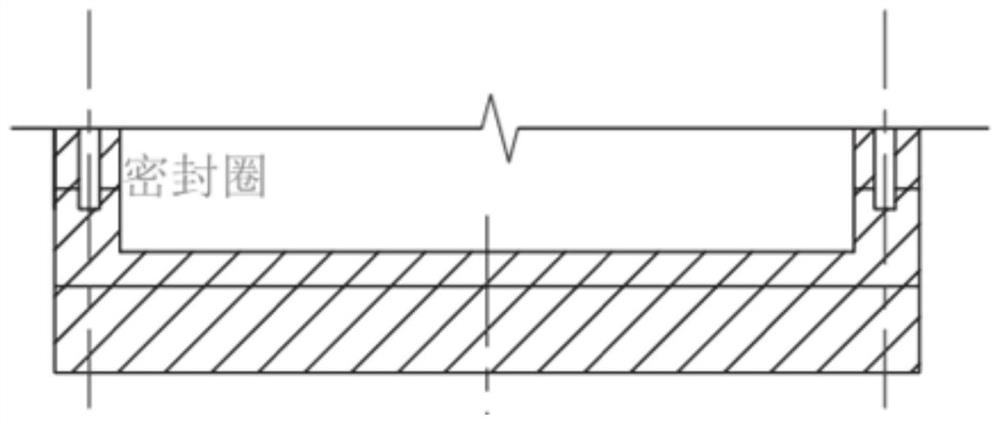

[0042] The loading mechanism includes a pressure applying mechanism, a test silo and a loading piston. The loading piston is a force-transmitting water-permeable piston. The application mechanism drives the loading piston to change its relative position with the test silo and / or change the output water pressure of the end face of the loading piston in the silo; the sensor of the monitoring mechanism is arranged inside the test silo through the side wall of the test silo, and the grouting mechanism The output is towar...

Embodiment 2

[0082]In another typical implementation of the present disclosure, as shown in the figure, a comprehensive test method for goaf water inrush and grouting treatment is proposed, using the goaf water inrush and grouting treatment as described in Example 1 Comprehensive test device.

[0083] Include the following steps:

[0084] Cover the test silo, fill the test silo with rock mass samples, and embed sensors in the samples;

[0085] Adjust the relative position of the test silo and the loading piston to make it coaxial, and the loading piston loads the sample in the test silo;

[0086] Remove the cover plate, adjust the loading piston to load the sample with ground stress and / or water pressure, and collect the parameters during the test;

[0087] Remove the loading piston, inject grout into the test silo to simulate treatment, collect parameters to check the grouting effect.

[0088] Using the test device in Example 1, prepare similar materials to simulate the surrounding roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com