Automatic walking control device and method for molten iron tank car

A molten iron tank car, automatic walking technology, applied in non-electric variable control, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve the problem of long time consumption, low precision, automatic slag removal, etc. problem, achieve the effect of reducing manpower input, improving positioning accuracy, and achieving optimal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

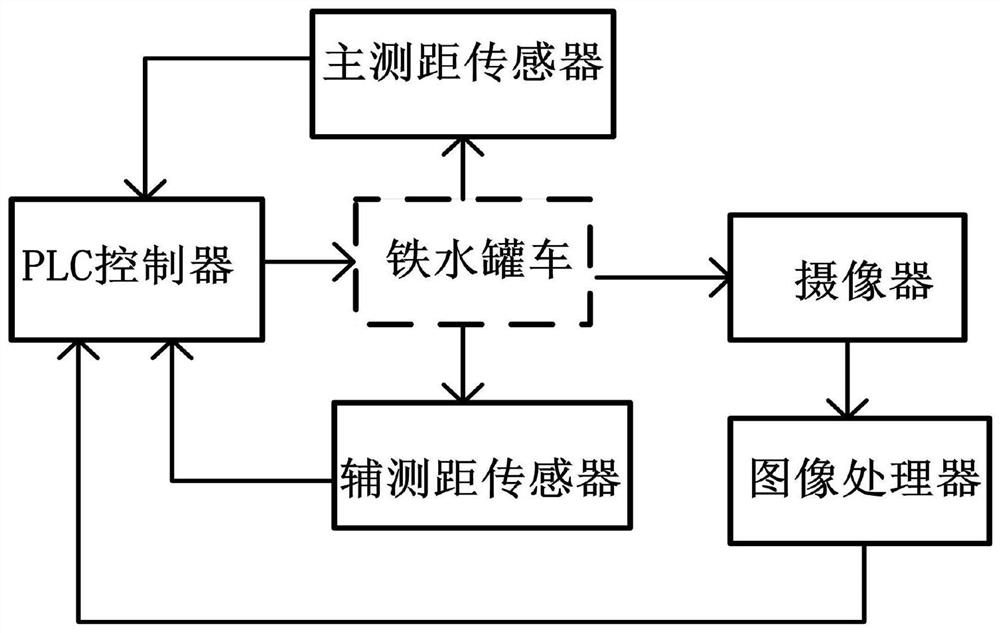

[0023] Such as figure 1 As shown, an automatic walking control device for a molten iron tank car includes a PLC controller, a distance measuring sensor, a camera and an image processor. Displacement, the camera is installed at the walking destination of the molten iron tank car, and the collected walking images are transmitted to the image processor, the ranging sensor and the image processor are connected to the input end of the PLC controller through a cable, and the output of the PLC controller The terminal is connected with the traveling drive motor of the molten iron tank car through a cable.

[0024] The ranging sensor is mainly used to collect the real-time displacement of the molten iron tank car at a predetermined frequency, and transmit the collected real-time displacement to the PLC contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com