Method and system for simulating deformation of natural fracture sliding shear shale gas horizontal well casing under multi-stage fracturing

A technology for natural fractures and shale gas, which is applied in the field of casing deformation simulation of natural fractures slipping and shearing shale gas horizontal wells under multi-stage fracturing, can solve problems such as lack of analysis and research, and reduce the probability of failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It will be appreciated that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

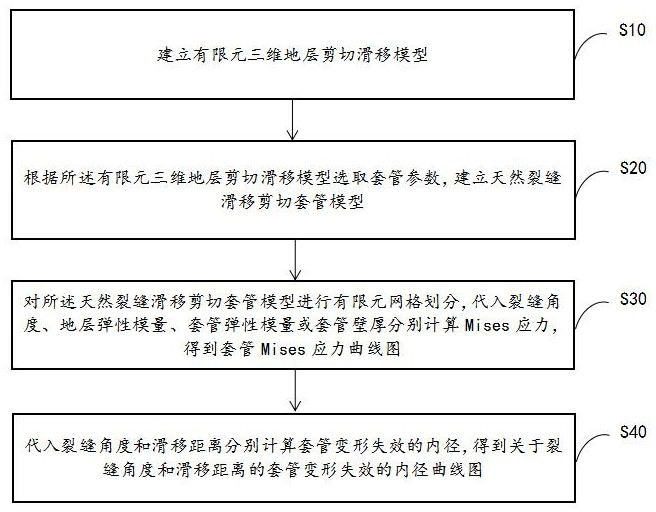

[0046] Refer figure 1 , figure 1 The first embodiment of the present invention is proposed for the first embodiment of the present invention.

[0047] In the first embodiment, a multi-stage fracturing of natural crack sliding shearing sheet rock gas horizontal well sleeve deformation simulation method, including the following steps:

[0048] Step S10: Establish a finite element three-dimensional formation shear slip model;

[0049] Step S20: Select the casing parameters based on the finite element three-dimensional formation shear slip model, establish a natural crack slip shear sleeve model;

[0050] Step S30: Finite element mesh is performed on the natural crack slip shear sleeve model, and the formation of the crack angle, formation elastic modulus, sleeve elastic modulus or sleeve wall thickness calculates Mises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com