Damping structure for projection equipment manufacturing

A technology of projection equipment and shock-absorbing hammer, which is applied in the direction of mechanical equipment, manufacturing tools, springs/shock absorbers, etc., can solve problems such as shortening the service life of stamping structures, failure of shock absorption, and large wear of stamping structures, so as to reduce wear , extended service life, and reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

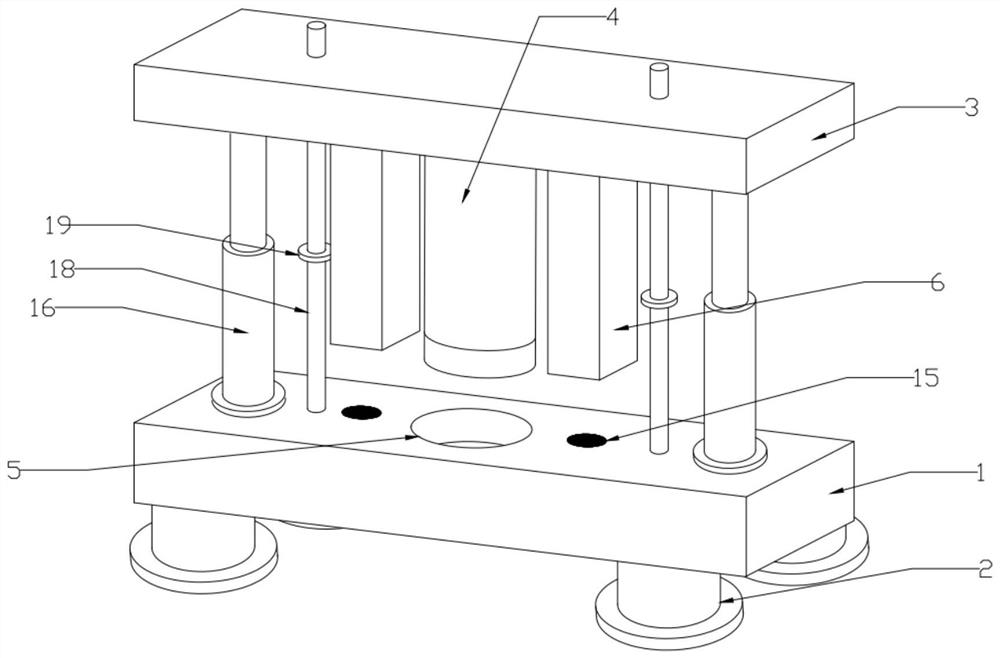

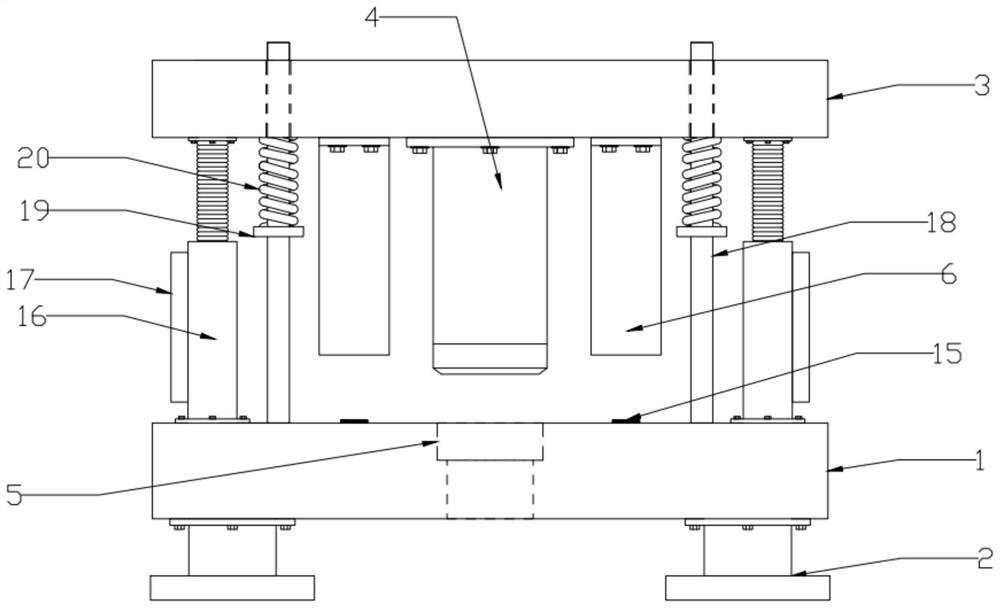

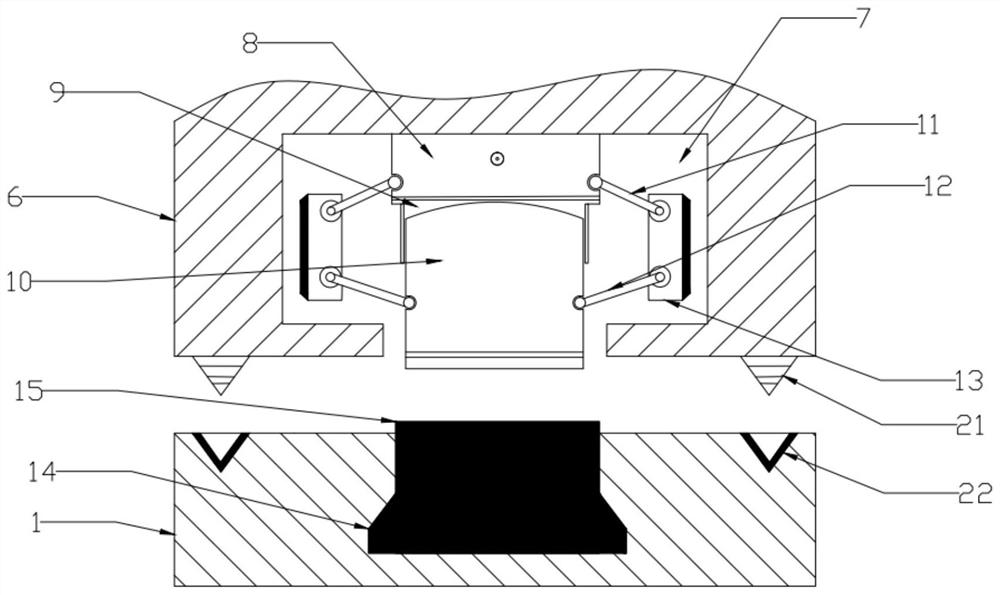

[0019] combined with figure 1 to attach image 3 , a shock-absorbing structure for the manufacture of projection equipment, comprising a lower mold base 1, support legs 2 are installed at the four corners of the lower mold base 1 through bolts, and a die structure is installed at both ends of the lower mold base 1 , an upper mold base 3 is installed between the upper ends of the die structure, and a stamping upper die 4 is installed in the middle of the lower die base 3 through bolts, and the upper middle of the lower die base 1 is connected to the stamping upper die 4 Correspondingly, there is a stamping lower die 5, a guide structure is installed between the upper die base 3 and the lower die base 1 and close to the die structure, the upper die base 3 and the lower die base 1 A shock absorbing device is installed between and close to the guide structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com