Hat and coat stand metal plate assembly, assembling method thereof and vehicle

A coat rack and sheet metal technology, applied in the field of body sheet metal, to achieve the effect of easy installation, taking into account the requirements of structural strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

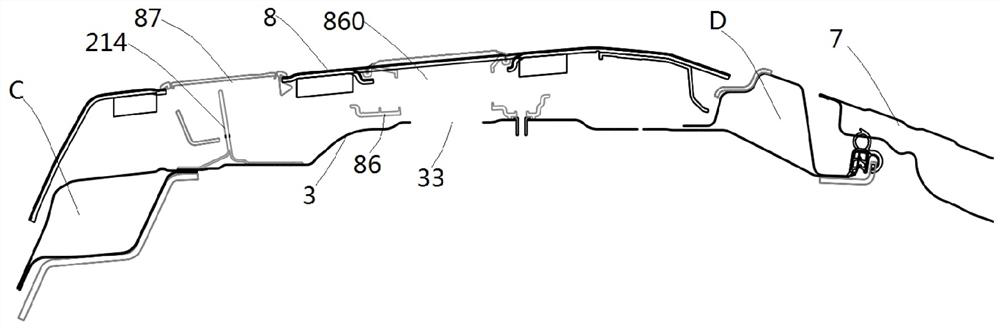

[0034] Orientation terms such as "front", "front side", "front", "rear", "rear side" and "rear" as used herein refer to the front-to-rear direction of the vehicle after the component is mounted to the vehicle . The "longitudinal", "longitudinal", and "longitudinal section" mentioned in this article are all based on the front and rear direction after the component is installed on the vehicle, while "transverse", "transverse", and "cross-section" mean perpendicular to the longitudinal direction .

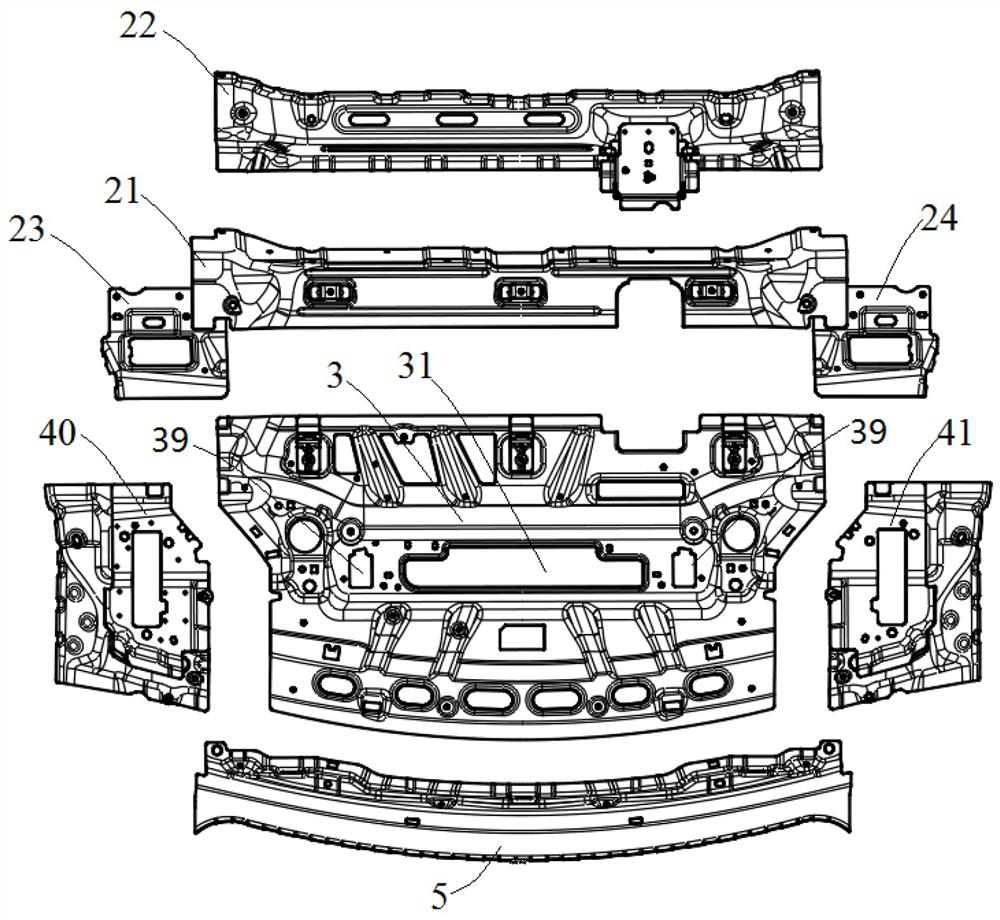

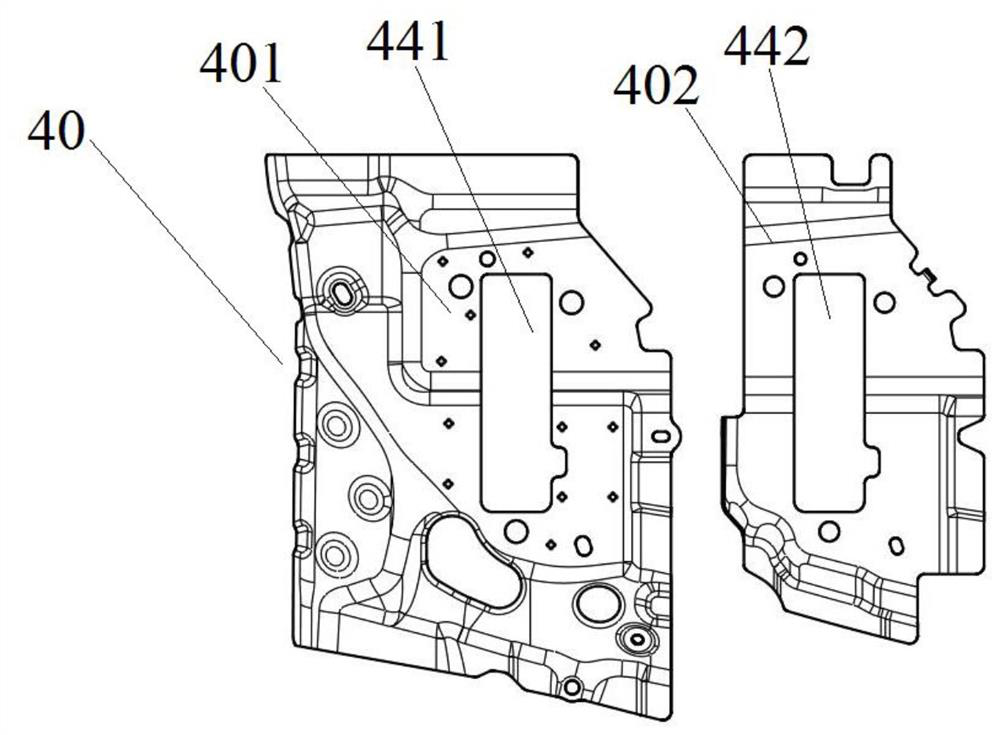

[0035] refer to figure 1 and figure 2 , respectively show an exploded view and an assembled view of the coat rack sheet metal assembly according to an embodiment of the present invention. The coat rack sheet metal assembly according to the embodiment of the present invention comprises: a coat rack sheet metal body 3; a front coat rack sheet metal 2 connected to the front side of the coat rack sheet metal body; The left tailgate hinge reinforcement plate 40 and the right tailgate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com