Mechanism capable of firstly distinguishing direction and then directionally turning at high speed and implementation method of mechanism

A flipping mechanism, high-speed technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of low efficiency, inability to realize fully automatic assembly of products, large manual workload, etc., to improve production efficiency, high-efficiency fully automatic assembly The effect of testing and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

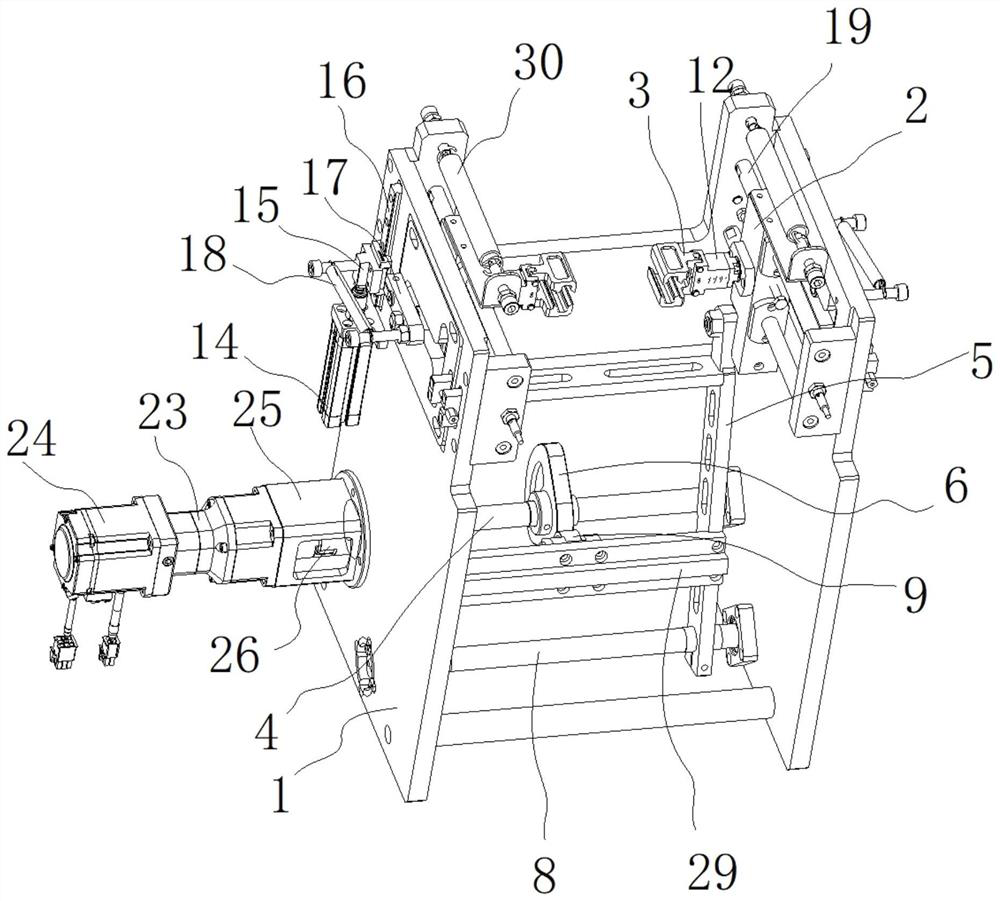

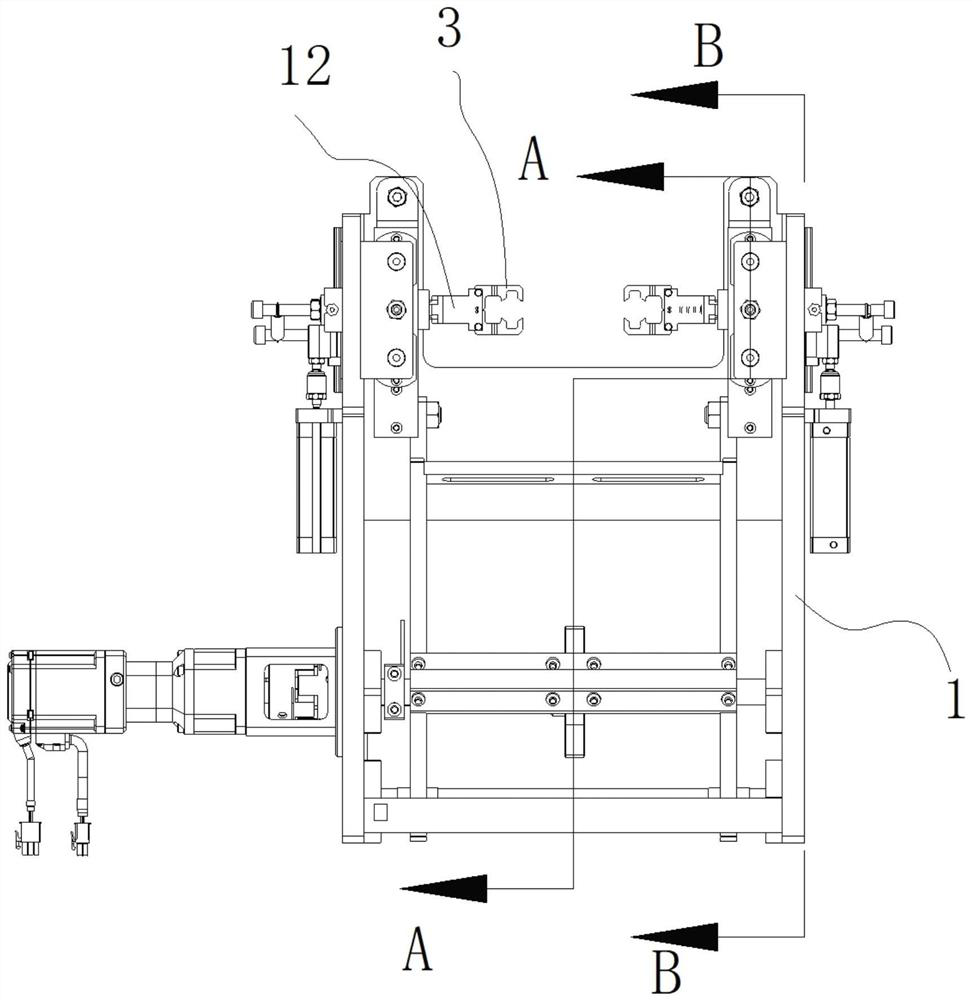

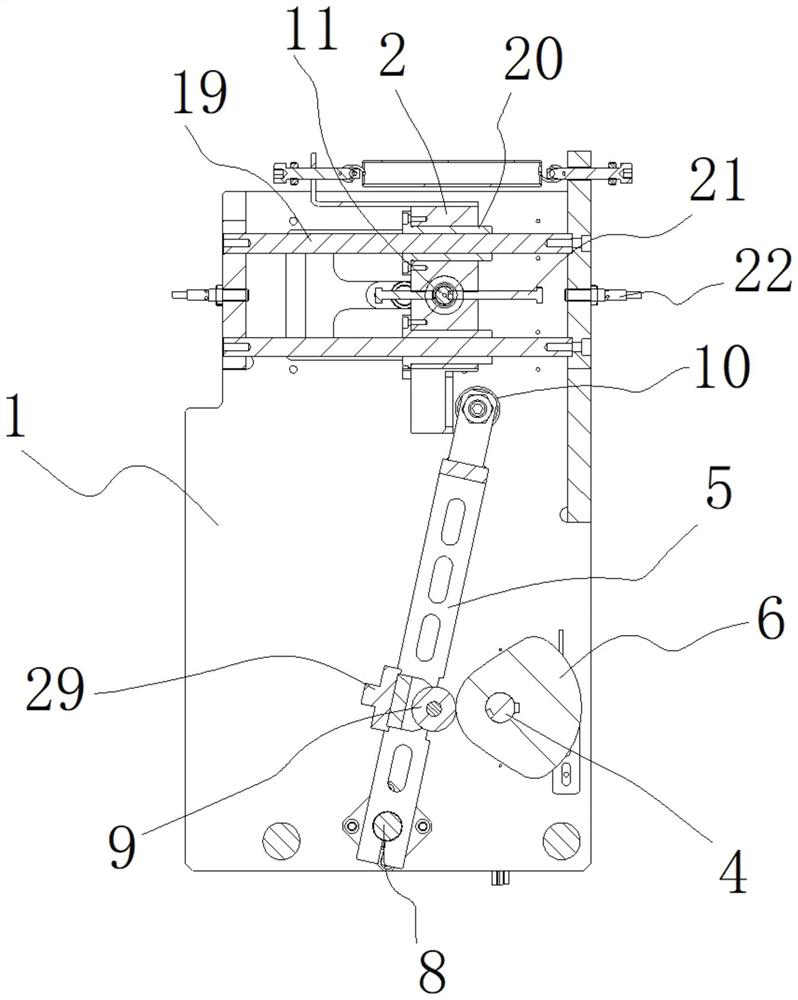

[0034] Embodiment 1: As shown in the figure, a high-speed directional flip mechanism that distinguishes first and backward, includes an operating frame 1, and the operating frame 1 is provided with a sliding seat 2 that can slide along the operating frame 1. The described The sliding seat 2 is provided with a reversible and clamping jaw 3 . The sliding seat 2 is slidably displaced by the cam assembly, and the gripper 3 is turned over by the stretching assembly; the cam assembly includes a motor shaft 4 and a swing arm 5, and the motor shaft 4 is covered with a The motor shaft 4 rotates the cam 6, one end of the swing arm 5 is fixed to rotate with the operating frame 1, the cam 6 drives the other end of the swing arm 5 to swing, and the swing arm 5 drives the sliding seat 2 to slide, the jaws 3 slide and move along the track of the track plate 7 in the operating frame 1, and the track of the track plate 7 is in the shape of a "T"; The clamping jaw 3 in the track of the plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com