A secondary gas desulfurization purification device in fire flooding oil production

A purification device and fire-flooding technology, applied in gas fuel, gas treatment, petroleum industry, etc., can solve problems such as air pollution, inability to remove sulfur elements, environmental pollution, etc., and achieve the effect of improving reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

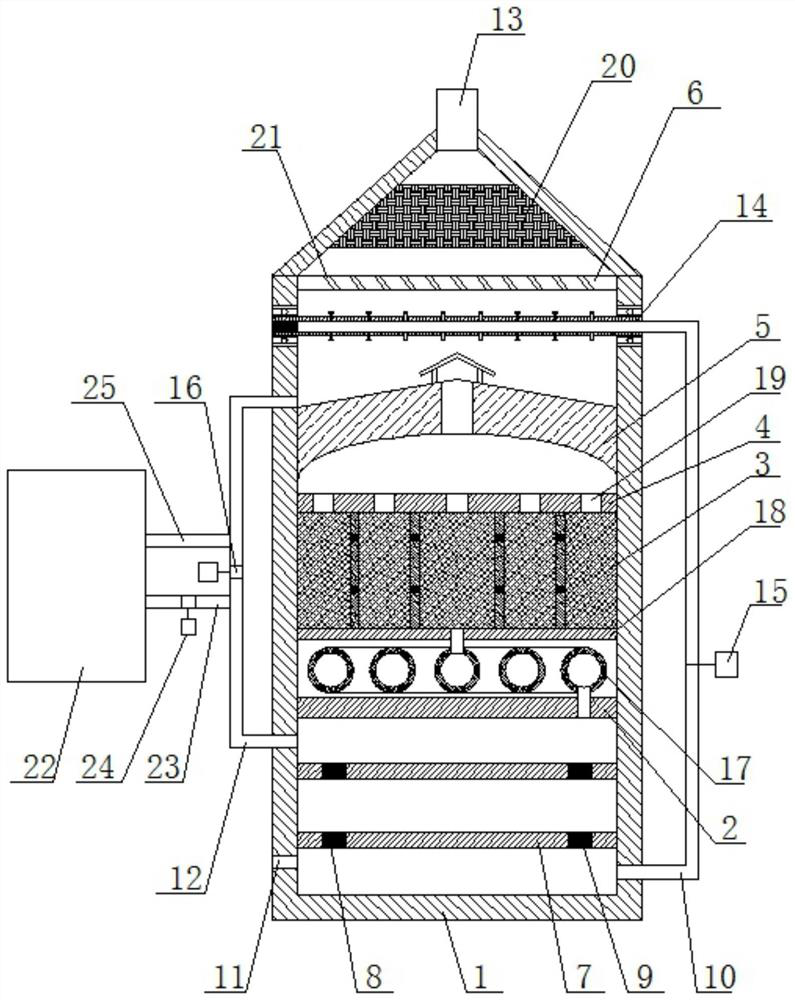

[0031] Such as figure 1 Shown is a secondary gas desulfurization and purification device in fire flooding oil production, including a tower body 1, the tower body is made of corrosion-resistant materials, and has good sealing performance, and is arranged in the tower body 1 from bottom to top. 1. From bottom to top, it is divided into the first partition body 2, the second partition body 18, the third partition body 4, and the fourth partition body 5 of the bath chamber, buffer chamber, oxidation chamber, accumulation chamber, spray chamber and drying chamber. and the fifth spacer 6; the bottom of the tower body 1 is provided with a secondary air inlet 11 communicated with the bath chamber, and the top of the tower body 1 is provided with an air outlet 13 communicated with the drying chamber; the bath chamber is The secondary gas passed through is used for bathing, and the gas easily soluble in water in the secondary gas is absorbed, and the buffer chamber buffers the absorbed...

Embodiment 2

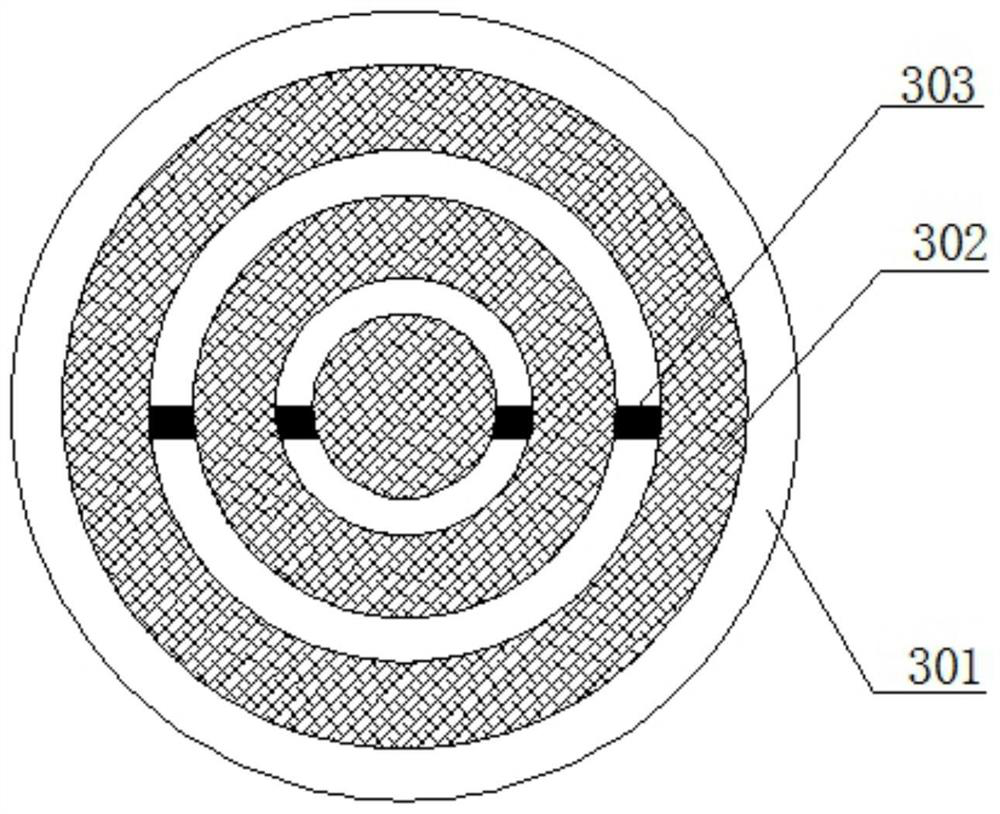

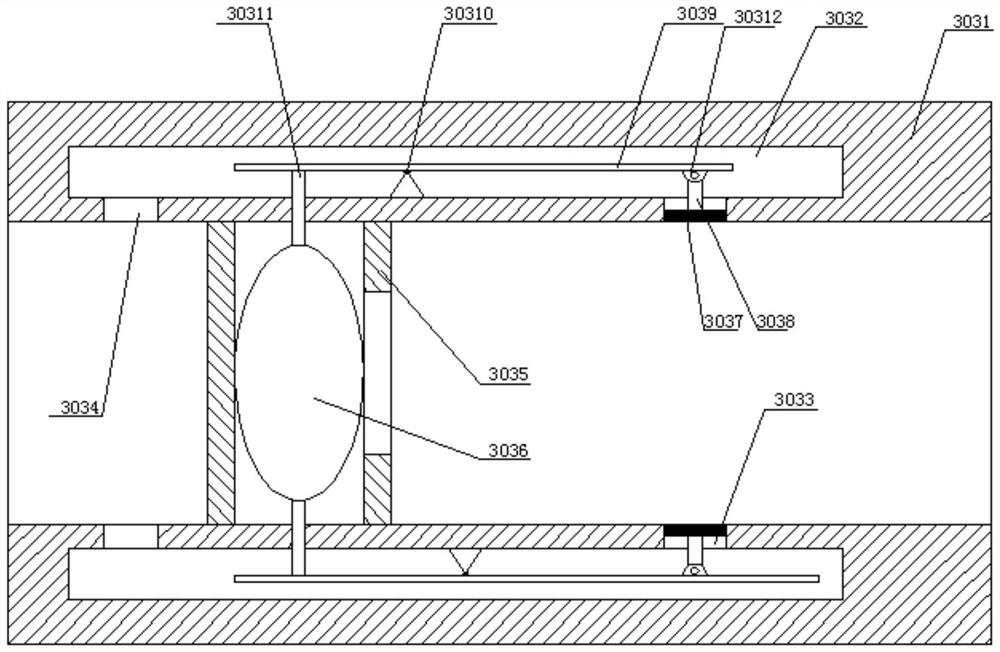

[0040] On the basis of Example 1, such as figure 2 The oxidation component 3 includes a plurality of concentrically arranged oxidation cylinders 301, and the oxidation filler 302 is filled between the plurality of concentrically arranged oxidation cylinders 301, and the cavities formed between the plurality of oxidation cylinders 301 pass through The thermal communication component 303 provided on the oxidation cylinder 301 is in communication, the bottom of the innermost oxidation cylinder 301 among the plurality of oxidation cylinders 301 is in communication with the buffer assembly 17, and the plurality of oxidation cylinders 301 form a plurality of annular cavities through which the A plurality of ventilation holes 19 provided on the third spacer 4 communicate with the gathering chamber; when the secondary gas entering the innermost oxidation cylinder 301 undergoes an oxidation reaction with the oxidation filler 302, when the heat generated is too large, The thermal commu...

Embodiment 3

[0047] On the basis of Example 1, in order to ensure that the fourth spacer 5 collects the gas after the oxidation reaction, and at the same time ensure that the spray liquid can be prevented from falling into the accumulation chamber when spraying, specifically as Figure 4 The fourth partition 5 includes a partition body 501. The end face of the partition body 501 located in the gathering chamber is an arc groove surface 502, and the end face located in the spray chamber is a convex surface 503 extending downward at both ends. The middle part of the partition body 501 is provided with a gas passage 504 connecting the gathering chamber and the spray chamber; the spray chamber is provided with a shielding top cover 505, and the shielding top cover 505 is fixedly connected to the top of the partition body 501 through a bracket 506, And the shielding top cover 505 is located directly above the gas channel 504 .

[0048] The shielding edges extending downward at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com