Preparation method of monocrystalline silicon-like ingot and monocrystalline silicon-like ingot

A technology of quasi-single-crystal silicon and single-crystal silicon ingots is applied to the preparation method of quasi-single-crystal silicon ingots and the field of quasi-single-crystal silicon ingots, and can solve the problems affecting the quality of quasi-single-crystal silicon ingots, reducing the phosphorus content of quasi-single-crystal silicon ingots, Phosphorus alloys are not melted and other problems, so as to improve the photoelectric conversion efficiency and improve the quality of cast single crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

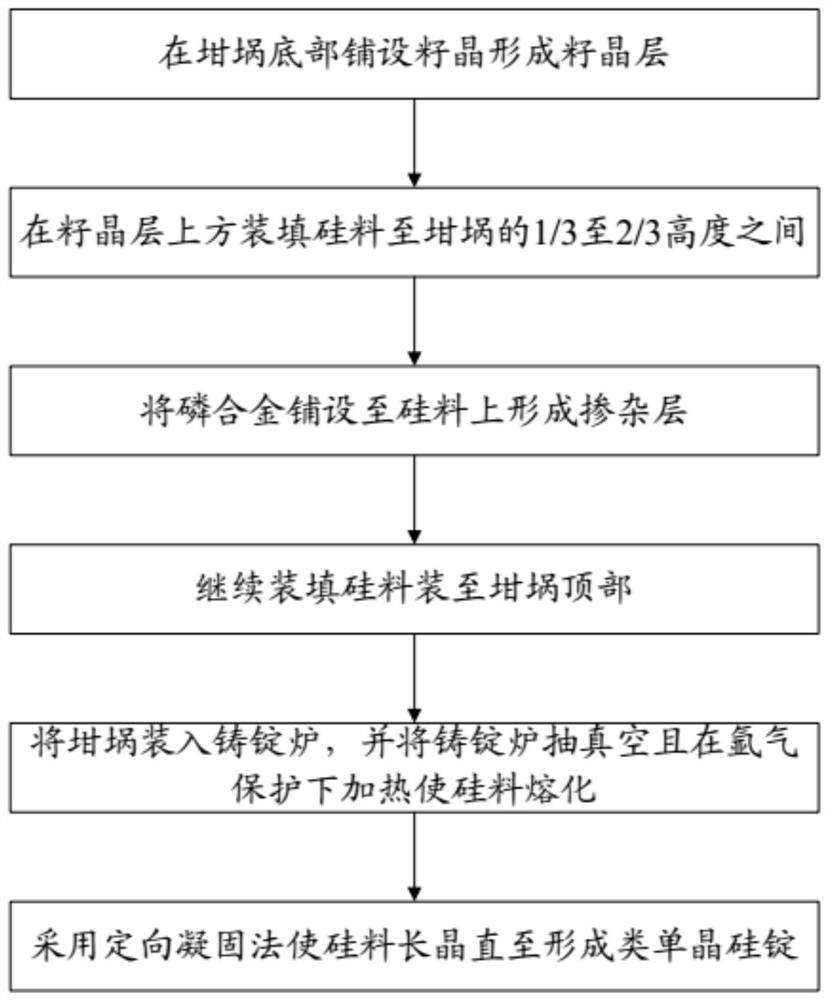

[0019] Please refer to Figure 1 to Figure 2 Shown is the embodiment of the preparation method of quasi-single crystal silicon ingot of the present invention, and the preparation method of described quasi-single crystal silicon ingot comprises:

[0020] laying seed crystals on the bottom of the crucible to form a seed crystal layer;

[0021] Fill the silicon material above the seed layer to between 1 / 3 and 2 / 3 of the height of the crucible;

[0022] laying phosphorus alloy on the silicon material to form a doped layer;

[0023] Continue to fill the silicon material to the top of the crucible;

[0024] Put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

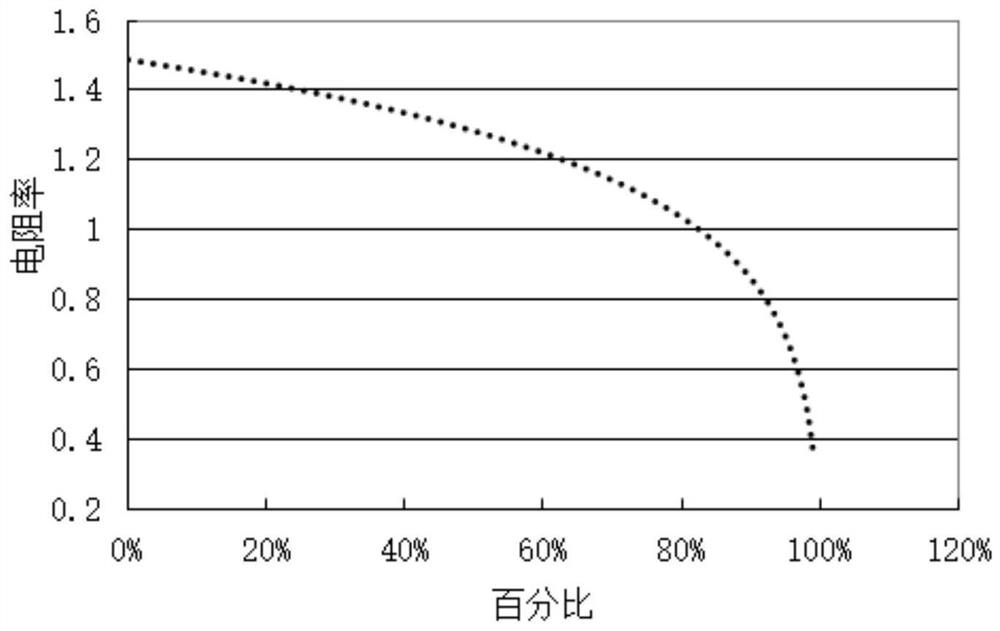

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap