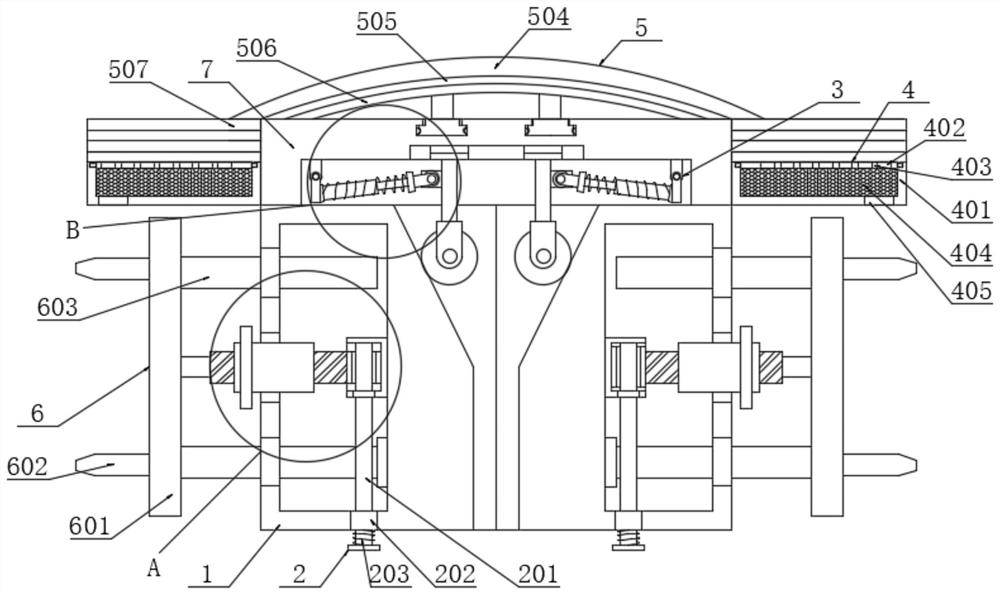

Road engineering seamless bridge deck expansion joint structure and construction method thereof

A technology for road engineering and expansion joints, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of damage to expansion joints, lack of waterproof capability of bridge expansion joints, and difficulty in replacing airbags, so as to improve the ability of protection and absorption, meet the The effect of reducing the difficulty of replacement and maintenance due to the needs of construction and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

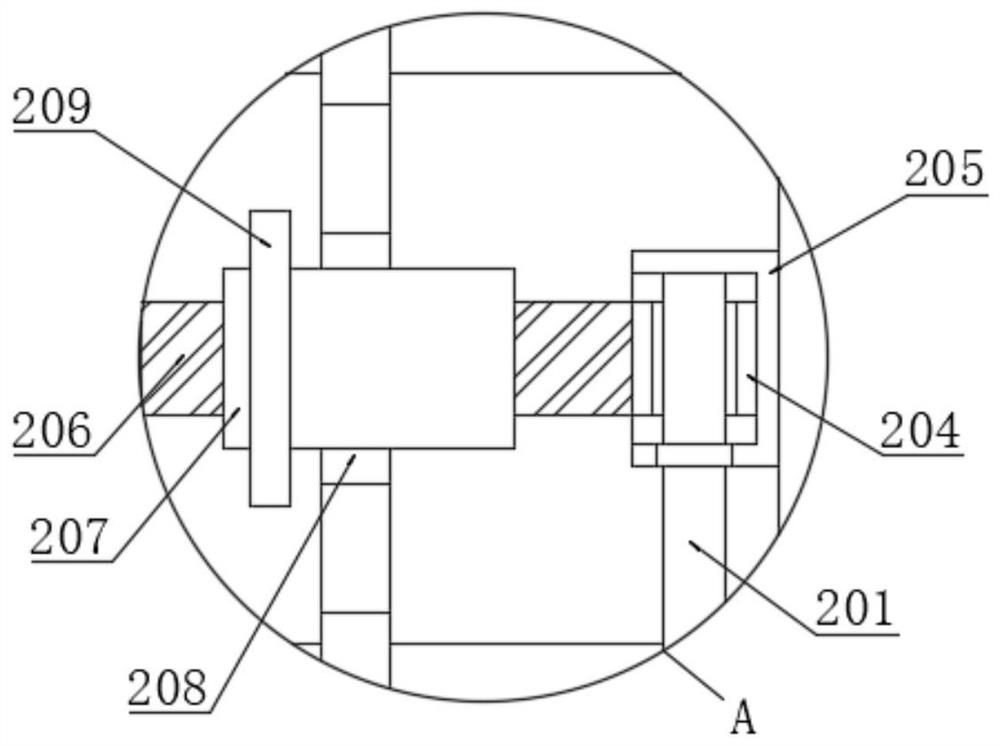

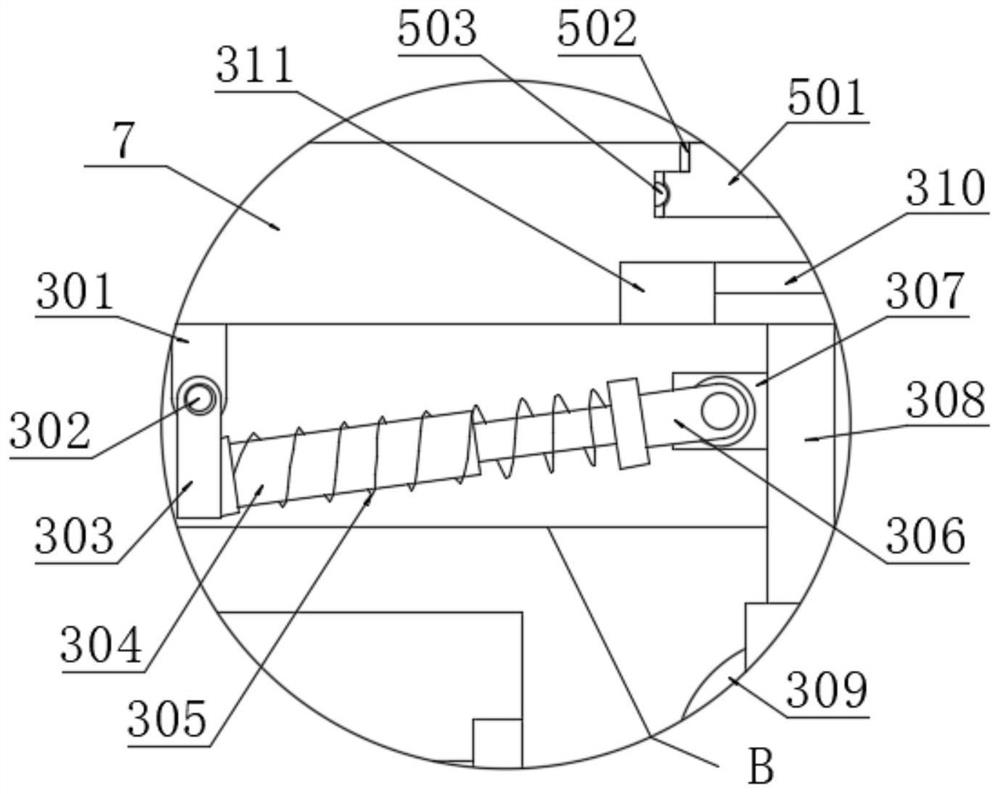

[0044] The implementation method is as follows: the insertion rod is pre-assembled into one side of the bridge deck through the anchor rod 602 on one side and bonded, at this time, the second sliding rod 603 is slid into the second sliding sleeve on the side of the elastic body 1 Close the limit, and screw the threaded column 206 connected to one side of the insert 601 into the threaded cylinder 207. At this time, the threaded cylinder 207 is driven to rotate by turning the handle, and the threaded cylinder 207 rotates to drive the threaded column 206 of the threaded connection to move inwardly The movement of the threaded post 206 can drive one side of the limit block 204 to snap into the limit seat 205. At this time, the second slide bar 603 at the bottom can be pulled upward to reset and snap into the limit block 204, and then the threaded post 206 and the insert The insert 601 is movable and clamped, and then the elastic body 1 and the bridge deck are clamped and limited. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com