Stainless steel wet film humidifier capable of automatically moving.

An automatic moving, humidifier technology, applied in air humidification systems, heating methods, lighting and heating equipment, etc., can solve problems such as inability to charge by itself, inconvenient installation and handling, and inability to remote control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

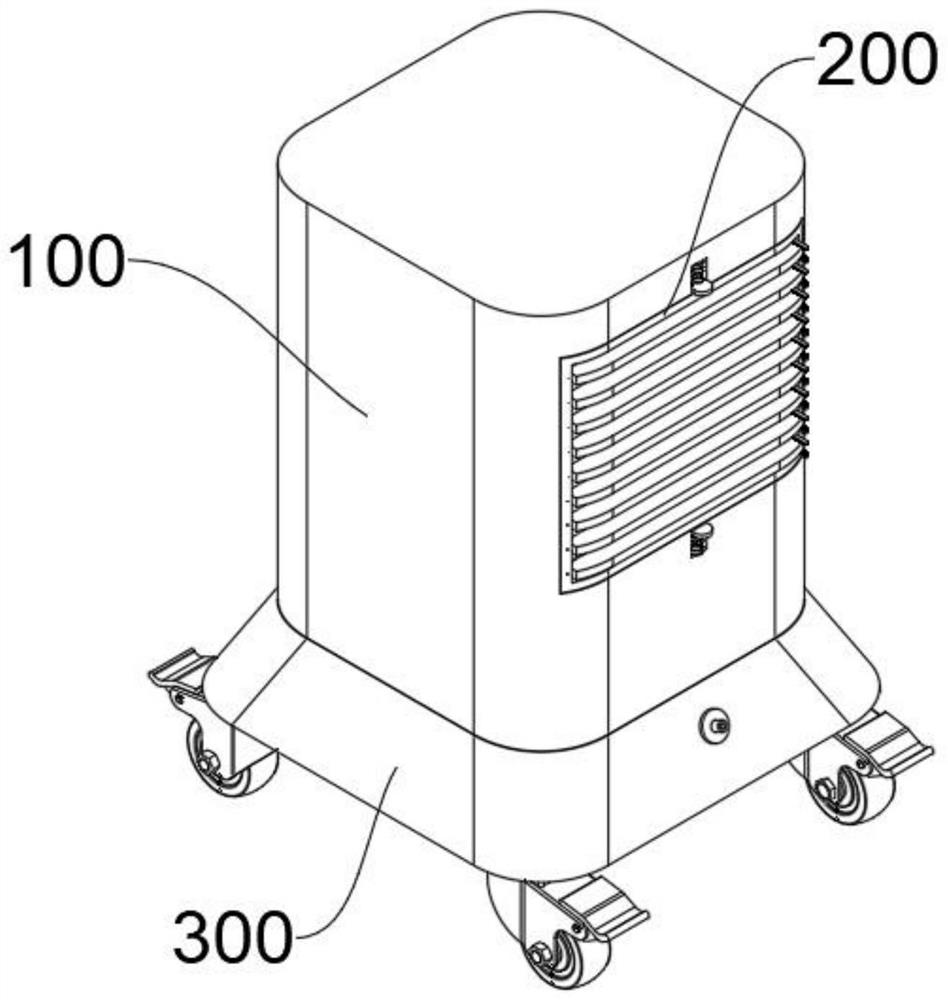

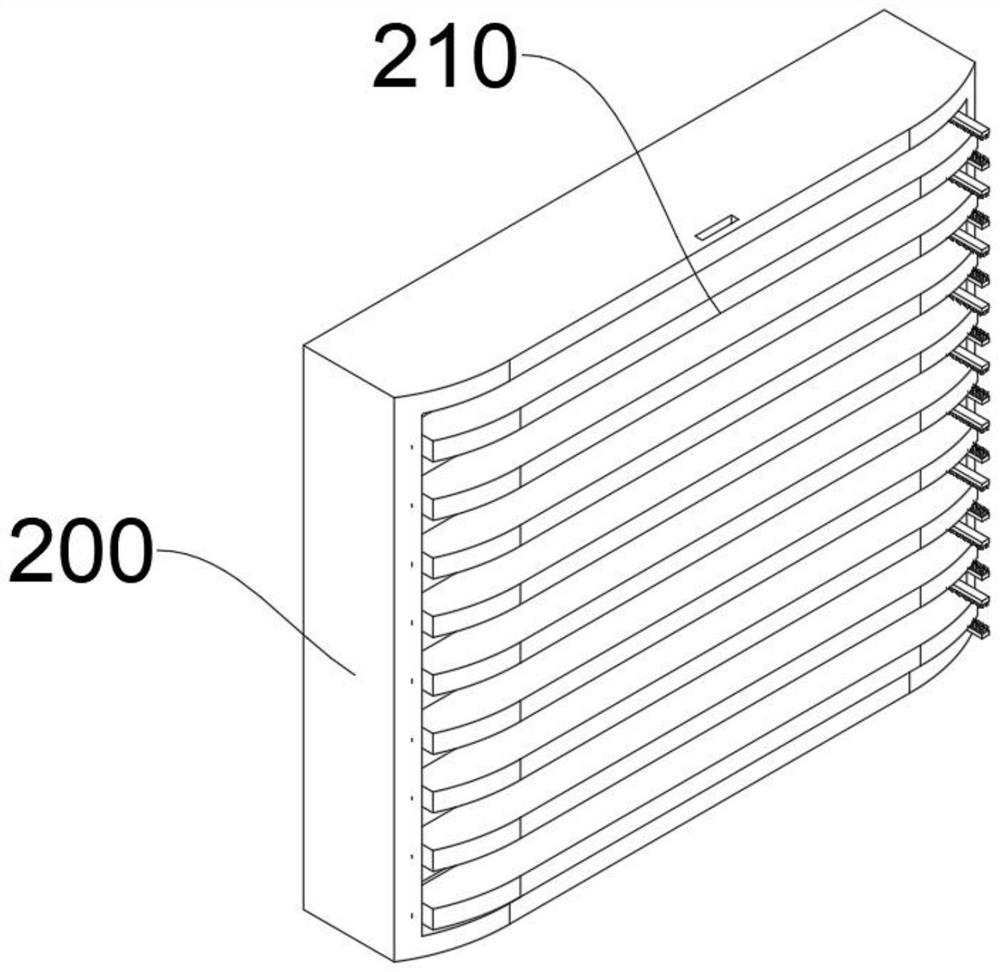

[0041] see Figure 1-Figure 11 As shown, this embodiment provides an automatic mobile stainless steel wet film humidifier, including at least:

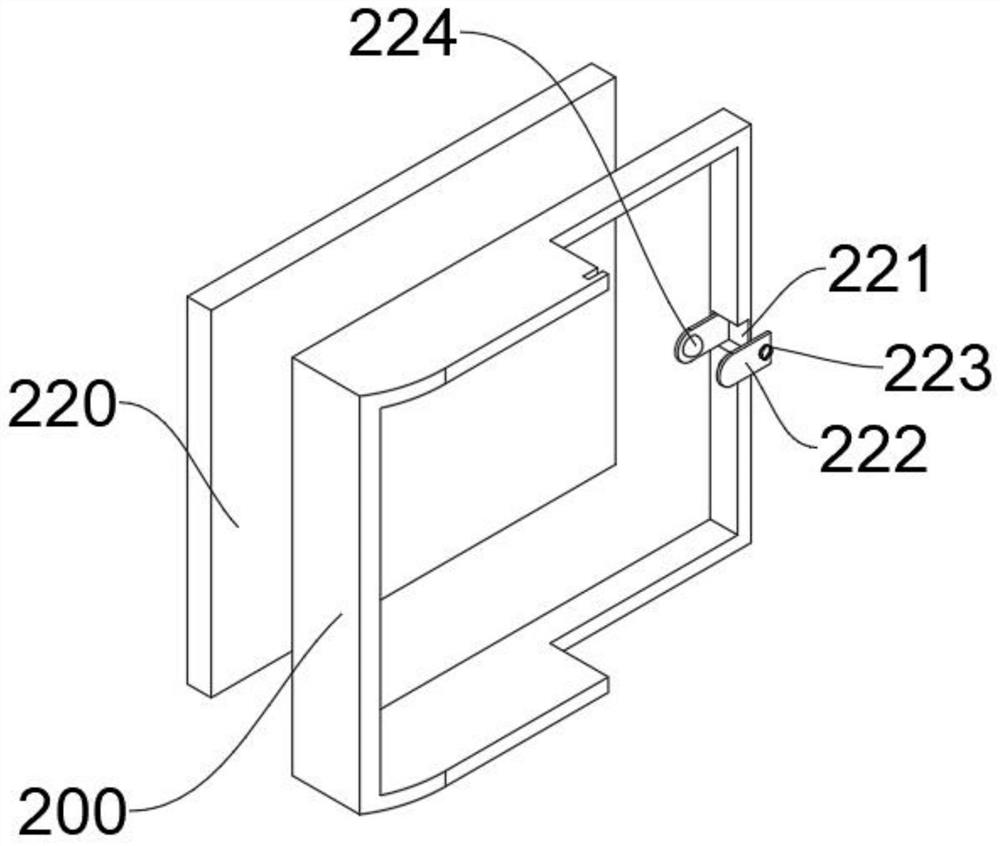

[0042]The humidifier body 100 has two symmetrical limiting grooves 110 on the edge of the humidifier body 100 near the air outlet. The limiting grooves 110 are connected to the humidifier body 100 inside. The end of the clamping plate 111 extends into the air outlet of the humidifier body 100, and the clamping plate 111 can be pushed up and down to slide inside the limit groove 110, so that the end of the clamping plate 111 moves up and down inside the air outlet of the humidifier body 100, and the top of the clamping plate 111 An adjustment plate 112 is provided, and the end of the adjustment plate 112 protrudes from the inside of the limit groove 110, so that it is convenient to hold the end of the adjustment plate 112 to drive the clamp plate 111 to move up and down, and the limit spring 113 is fixedly connected between the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com