Fully prefabricated concrete plate cap component and construction method thereof

A technology of prefabricated concrete slabs and construction methods, which is applied in the direction of building components, floor slabs, structural elements, etc., can solve the problems of limited application of prefabricated beam components, single type of prefabricated components, and inability to prefabricate beams and slabs and construct them at the same time, so as to save The effect of disassembly and assembly time, improvement of production efficiency, and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

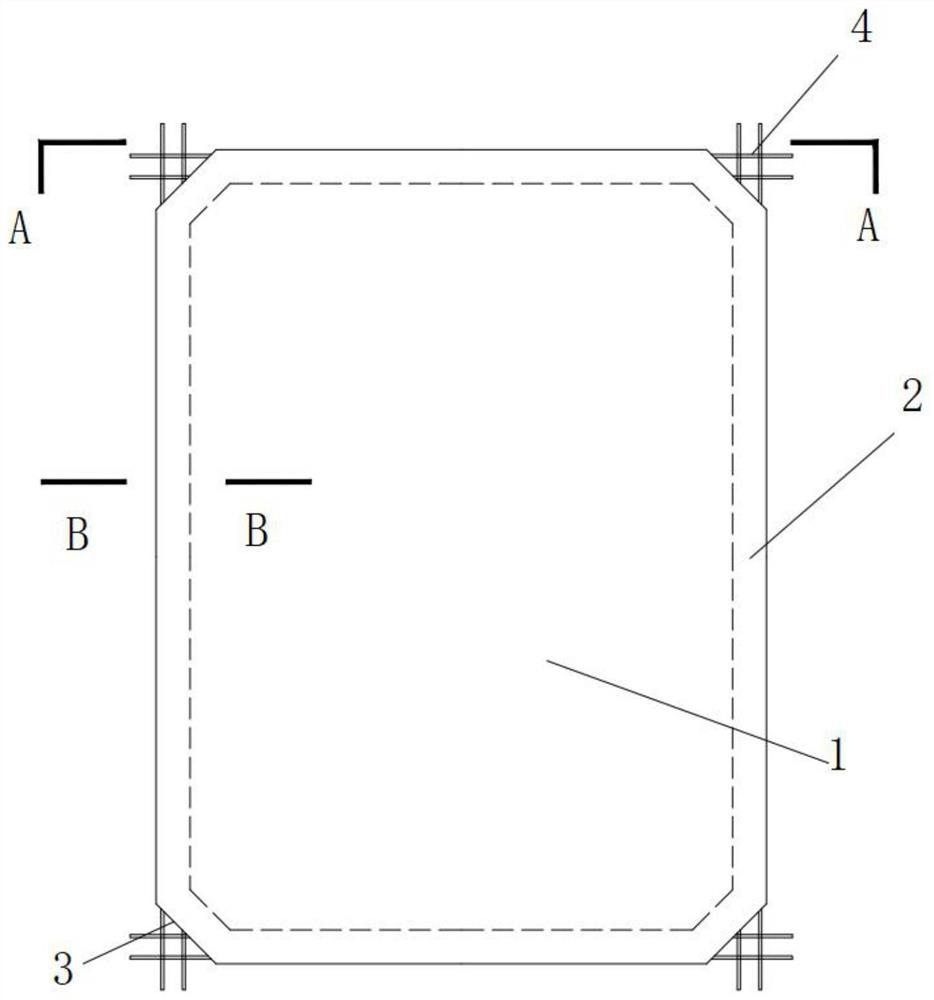

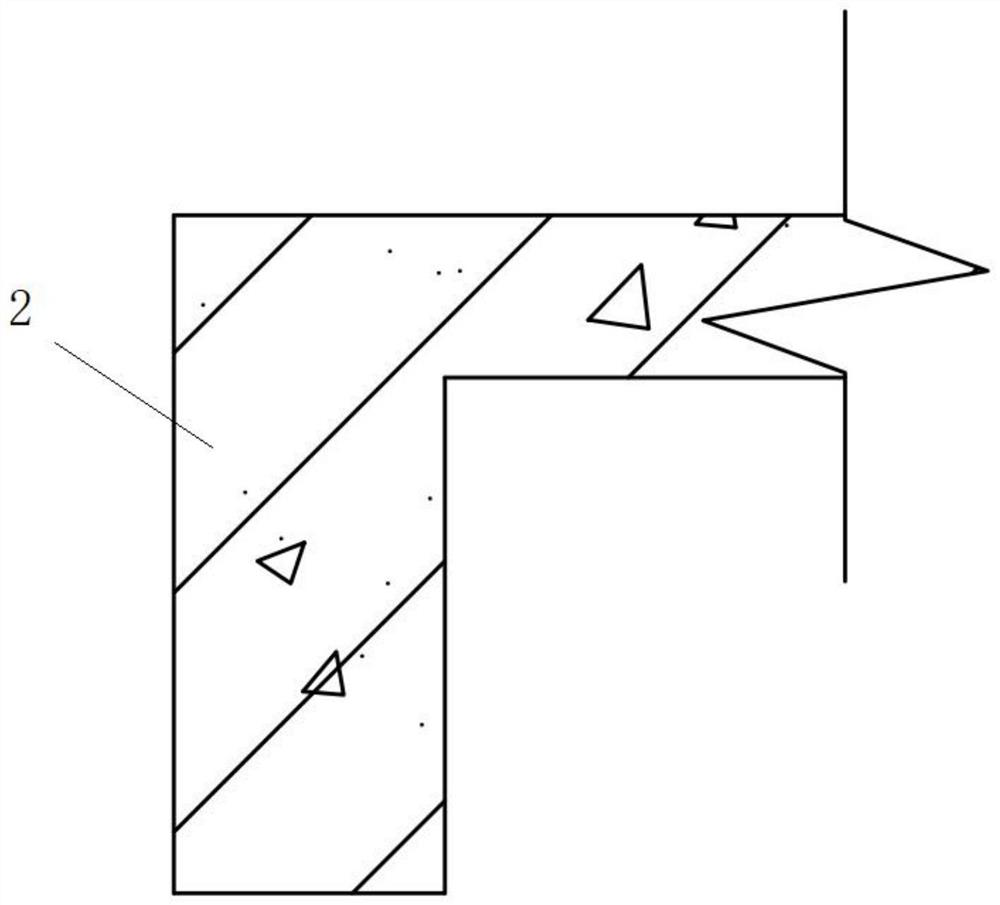

[0033] Such as figure 1 , figure 2 with Figure 5 , a fully prefabricated concrete slab cap member, including a prefabricated slab 1, the four sides of the prefabricated slab 1 are bent downwards to form a folded plate 2, and the four folded plates 2 surround to form a rectangular ring structure, with the rectangular ring shape The prefabricated slab 1 of the structure constitutes a beam structure, and the four corners of the prefabricated slab 1 are respectively provided with chamfered corner structures 3, and the folded slab 2 is provided with steel bars 4, and the two steel bars 4 in the folded slab 2 Both ends protrude outside the beam structure.

[0034] The construction method of the full prefabricated concrete slab cap member may include the following steps:

[0035] Before the prefabrication of the floor slab, the four sides of the prefabricated slab 1 are bent downward to form a folded plate 2, and the four folded plates 2 are surrounded to form a rectangular ring...

Embodiment 2

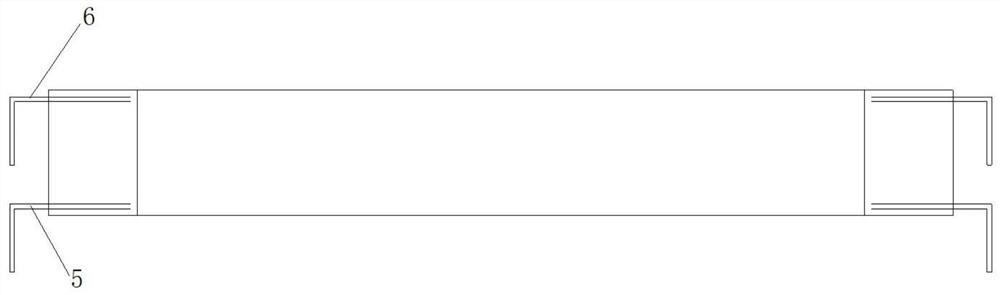

[0040] Such as image 3 As shown, a fully prefabricated concrete slab cap member is similar to Embodiment 1, the difference is that the steel bars 4 in the folded plate 2 include bottom stress bars 5 and top negative moment bars 6 .

[0041] Such as Figure 4 As shown, it is also possible to further configure stirrups 7 inside the folded plate 2 .

[0042] The construction method of the above-mentioned fully prefabricated concrete slab cap member can be more specifically, the steel bars 4 in the folded plate 2 include the bottom stress bars 5 and the top negative moment bars 6, and the stirrups 7 are arranged in the folded plate 2.

[0043] Such as Figure 4 As shown, it can be further provided that supports 8 are provided at the four corners of the full prefabricated concrete slab cap member.

[0044] Such as Image 6 As shown, it is also possible to further set a corbel piece 9 at the top position of the side of the support 8 .

[0045] The construction method of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com