The construction method of quickly dredging and plugging mines

A construction method and mine technology, applied in drilling equipment and methods, mining equipment, earthwork drilling and mining, etc., can solve problems such as wellbore blockage, and achieve the effect of easy mastery and low technical difficulty requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

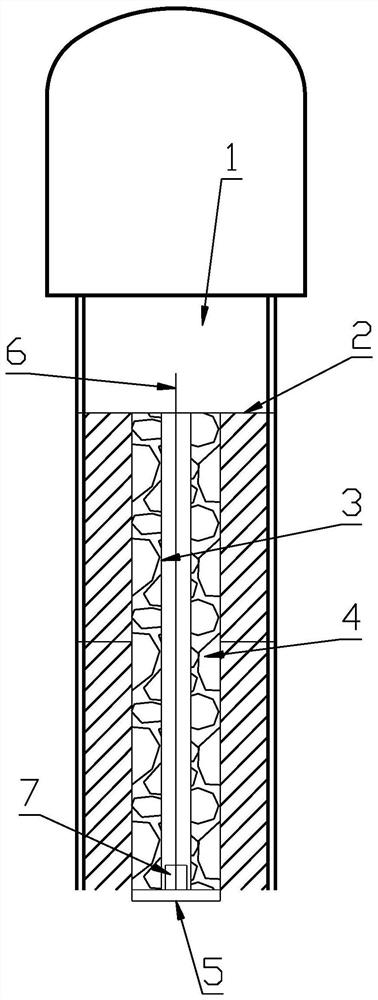

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] The construction method for quickly dredging a blocked mine includes the following steps:

[0021] Step 1: Set up a drilling rig operating platform 2 at the well blockage of mine 1. Before erecting, clean up the loose ballast within the erection range, and use concrete to level the uneven places within the erecting range; And can withstand the vibration and impact load during the drilling process to meet the requirements of safe operation;

[0022] Step 2: After the drilling rig operation platform 2 is erected, the drilling rig is hoisted to the drilling rig operation platform 2 and installed in place; the drilling rig can be of various types, preferably a geological core drilling rig; the drilling rig can usually be installed on the construction site. More than 3T hoist for hoisting;

[0023] Step 3: Install the drilling tool on the installed drilling rig; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com