A laser docking monitoring device for auxiliary platform docking system

An auxiliary platform and monitoring device technology, applied in transportation and packaging, special-purpose vessels, underwater operation equipment, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

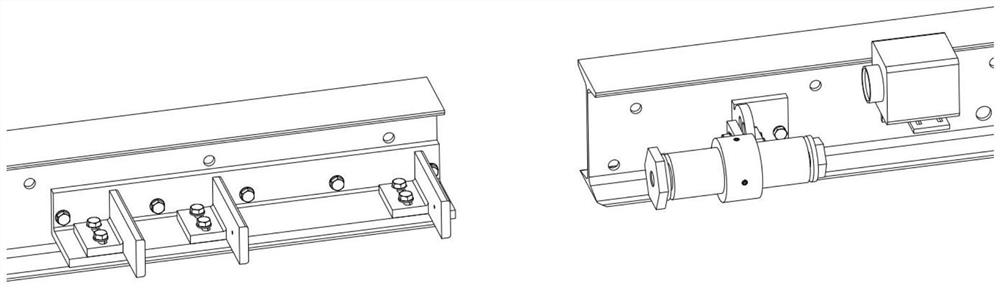

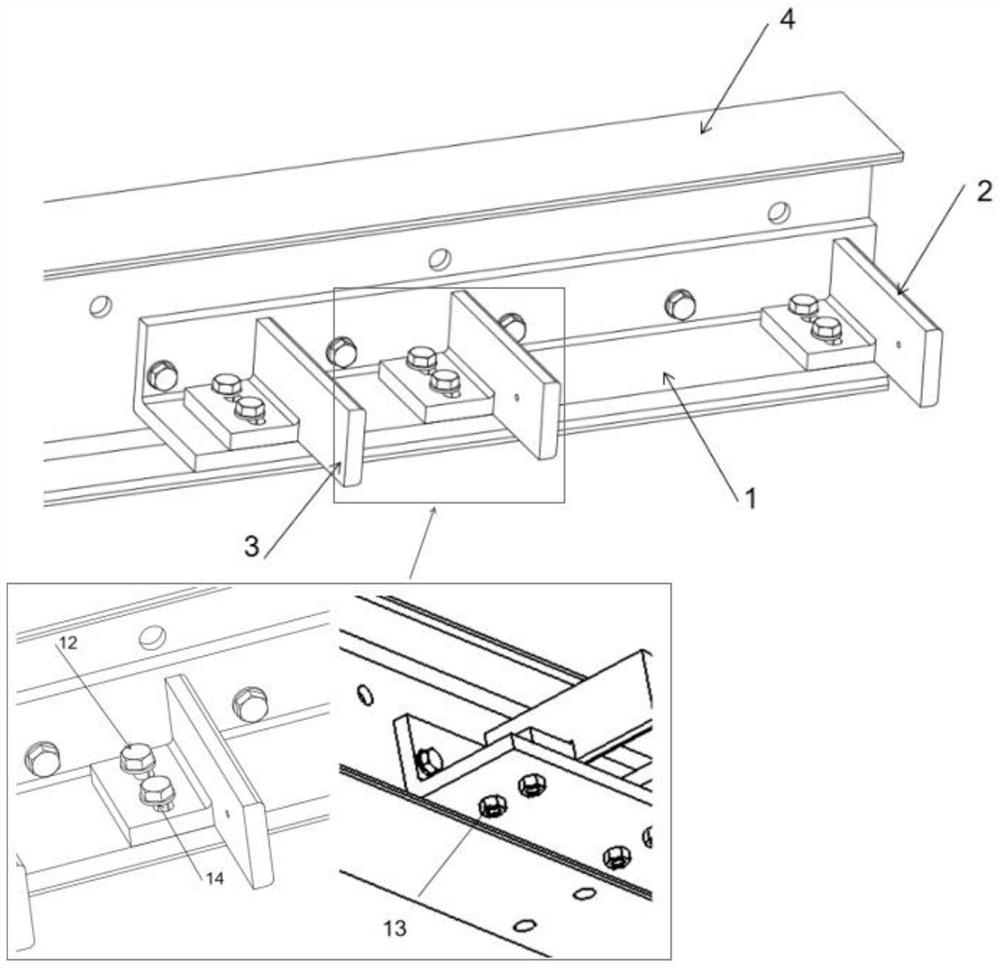

[0032] Specific implementation mode one: see Figure 1-7 This embodiment will be described. The laser docking monitoring device of the auxiliary platform docking system described in this embodiment includes the positioning hole plate assembly of the test platform part, the laser assembly and the camera assembly of the transfer platform.

[0033] The positioning orifice assembly of the test platform part includes a monitoring plate support 1, two monitor positioning orifice plates 2, a monitor reflector 3 and a test platform support 4, and the monitoring plate support 1 is vertically installed on the test platform support 4, two monitor positioning orifice plates 2 and a monitor reflection plate 3 are installed on the monitoring board support 1, and two monitor positioning orifice plates 2 are installed on one side of the monitor reflection plate 3, each Positioning holes are all designed on the positioning orifice plate 2 of each monitor.

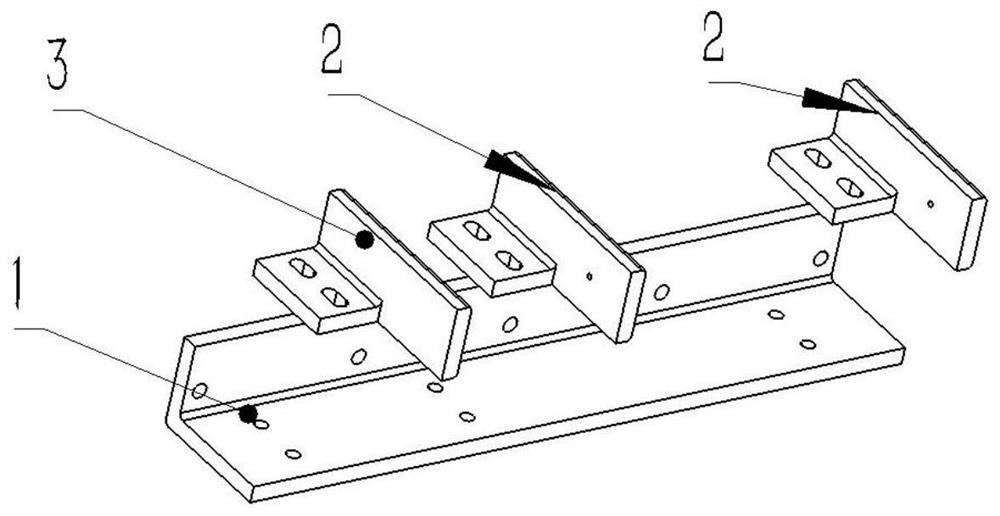

[0034] The laser assembly and came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com