Vulcanized part feeding device of multi-station press fitting equipment

A multi-station, vulcanized part technology, applied in conveyor objects, transportation and packaging, etc., can solve the problems of smashing, finger crushing, high rejection rate, and achieve the effect of improving production efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0026] Specific embodiments of the invention will be described in detail below.

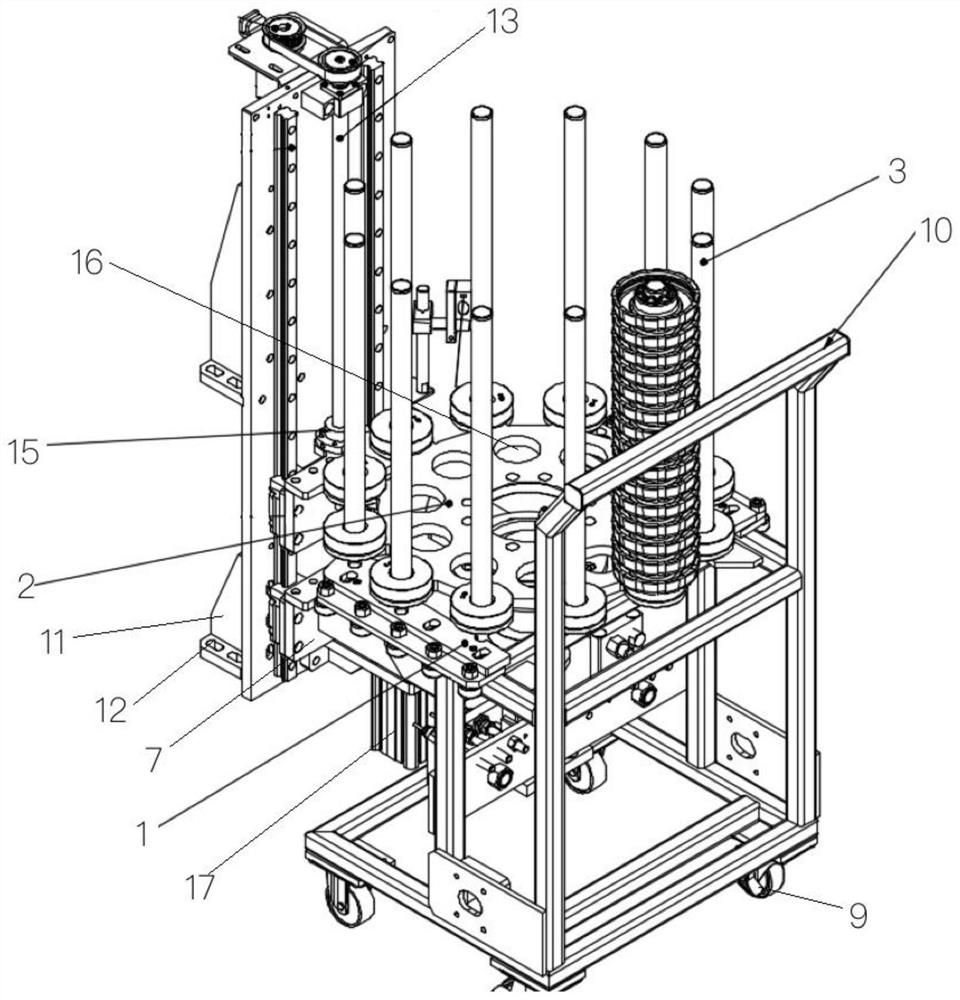

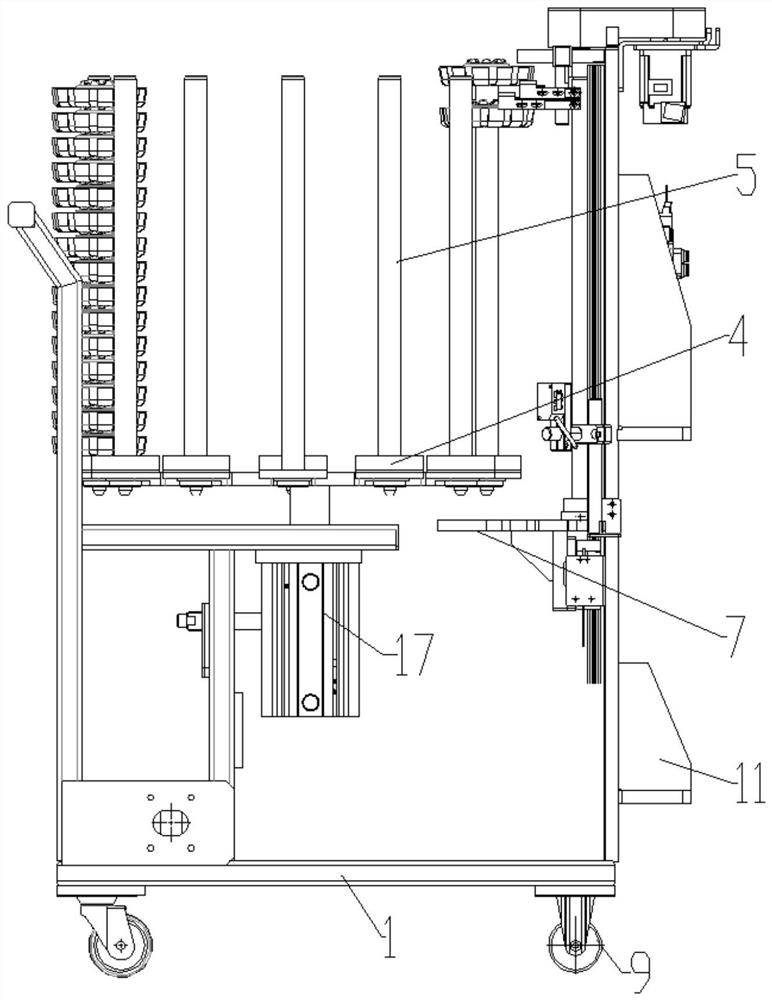

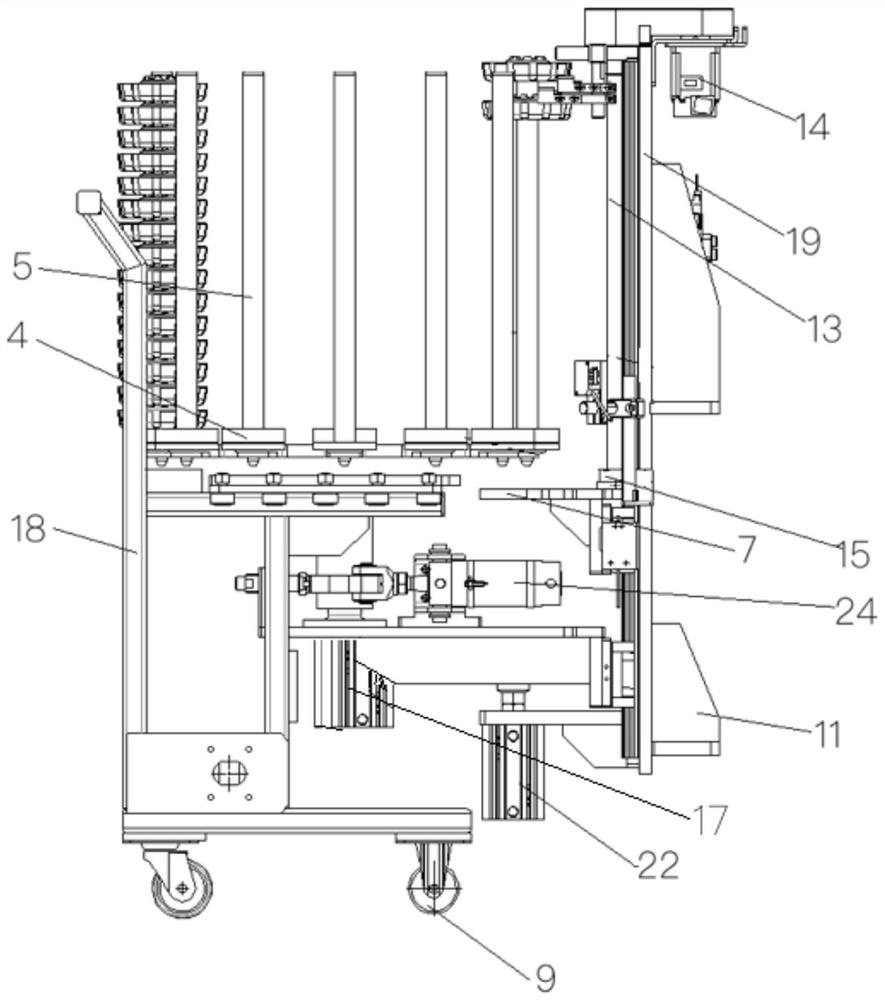

[0027] A vulcanized part feeding device for multi-station press-fitting equipment, such as Figures 1 to 6 As shown, it includes a frame 1 and a chassis 2 installed on the frame; a number of material rod assemblies 3 are fixed on the chassis, and the frame is provided with a lifting adjustment assembly for lifting the material rod assembly, and drives the chassis to rotate so that Align the required material rod assembly with the chassis rotation drive assembly of the lifting mechanism; when the workpiece is clamped on the material rod assembly of the aligning grab manipulator (that is, after the vulcanized parts on the rod body of the material rod assembly are used up), it can be passed The chassis rotates the drive assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com