A cotton cleaning device

A technology of cleaning and guiding cotton, which is applied in the direction of fiber cleaning, fiber cleaning machines, textiles and papermaking, etc. It can solve the problems of low efficiency and manpower consumption, and achieve the effects of thorough removal of impurities, improvement of quality and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

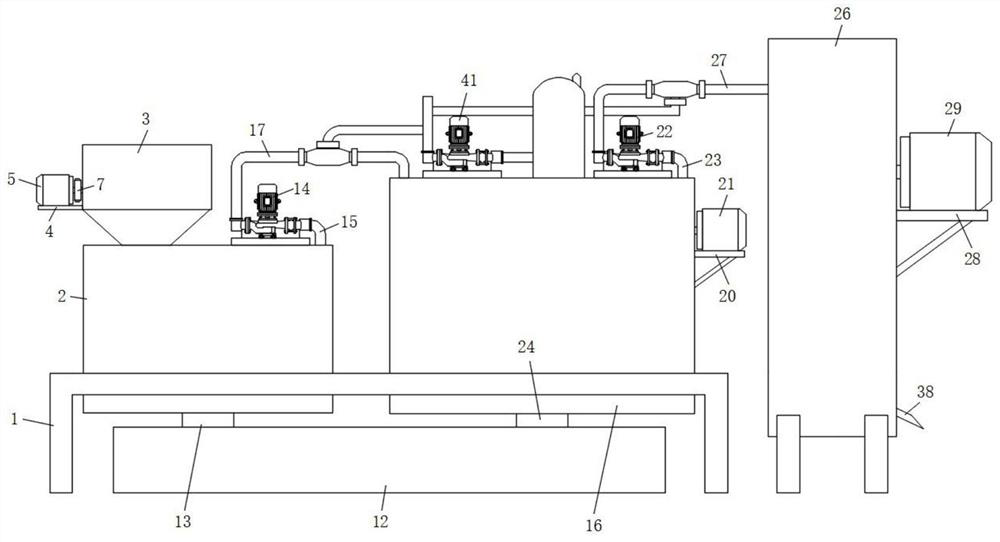

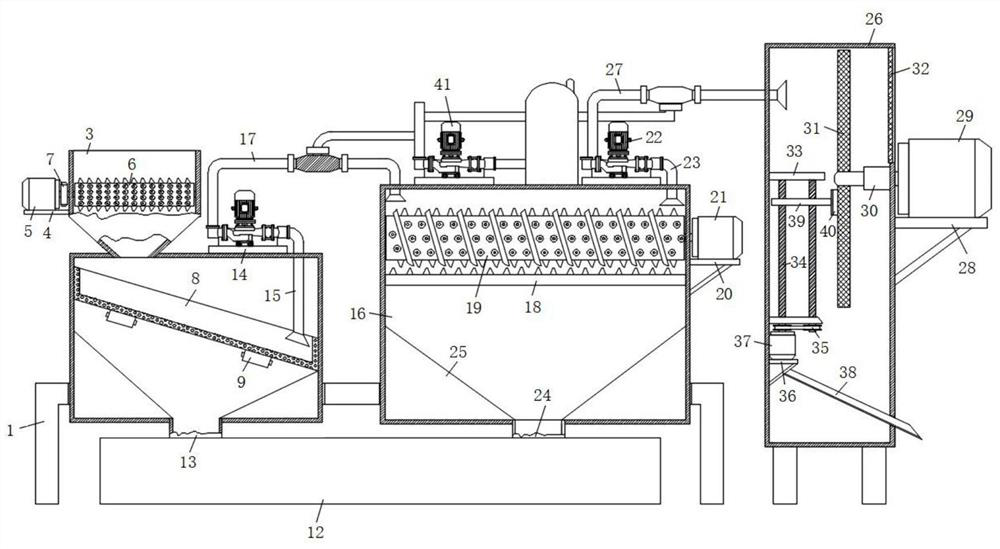

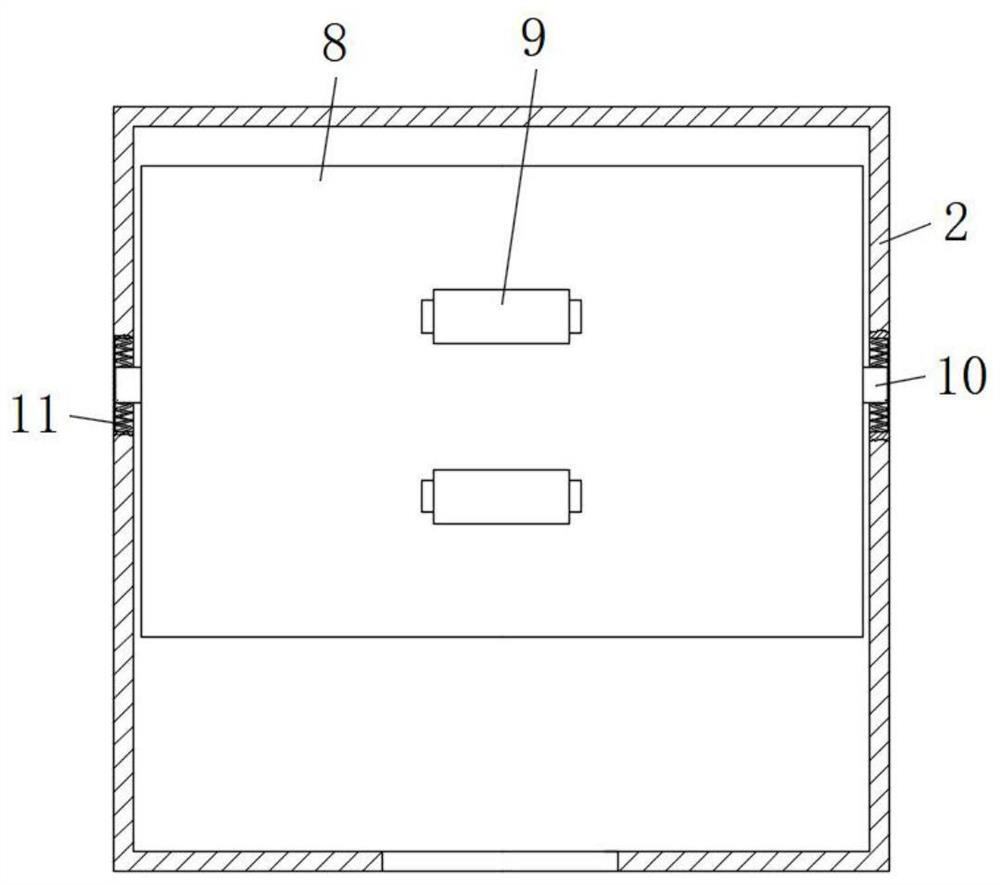

[0033] refer to Figure 1-6, a cotton cleaning device, comprising a work frame 1, a pretreatment box 2 is fixedly connected to one side of the top surface of the work frame 1, a tearing and crushing dish 3 is connected through the top side of the pretreatment box 2, and the middle part of the tearing and crushing dish 3 One side is welded with a horizontal plate 4, the top surface of the horizontal plate 4 is fixed with a servo motor 5 through screws, and the inner walls of the two sides of the tearing and crushing vessel 3 are also rotatably connected with crushing and tearing rollers 6, and one end of the two crushing and tearing rollers 6 passes through the tearing machine. The crushing dish 3 is rotatably connected through the gear set 7, and the output end of the servo motor 1 is fixedly connected with one of the crushing and tearing rollers 6. The upper inner wall of the pretreatment box 2 is also slidably connected with a screening disc 8, and the bottom surface of the s...

Embodiment 2

[0036] Such as figure 1 , 2 As shown in and 6, this embodiment is basically the same as Embodiment 1. Preferably, the anti-blocking mechanism 41 includes a booster pump 411 and an air storage tank 412, and the input end of the booster pump 411 is connected through the output end of the air storage tank 412. There is an air duct one 413, and the output end of the booster pump 411 is also fixed with an air distribution pipe 414, and both sides of the upper end of the air distribution pipe 414 are connected with an air guide pipe two 415, and one end of the air guide pipe two 415 is fixedly connected with an anti-blocking pipe 416, and Two anti-blocking pipes 416 are respectively socketed in the middle of the first cotton guide tube 17 and the third cotton guide tube 27, and the second control valve 417 is installed on the second air guide tube 415, and the second control valve 418 is installed on both sides of the anti-blocking tube 416 .

[0037] The booster pump 411 and the ...

Embodiment 3

[0040] Such as figure 2 and 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two crushing and tearing rollers 6 are provided and symmetrically distributed on the front and rear sides of the upper end of the tearing and crushing dish 3, and two limiting blocks 10 are provided and are distributed in the screening area. The positions on both sides of the front and rear ends of the disk 8.

[0041] In this embodiment, there are two crushing and tearing rollers 6, which are symmetrically distributed on the front and rear sides of the upper end of the tearing and crushing dish 3, so that the crushing effect of the sand cotton raw material is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com