Controllable plate type pulsating heat pipe heat transfer system with external oscillating source

A pulsating heat pipe and heat transfer system technology, applied in the field of controllable plate pulsating heat pipe heat transfer system, can solve the problems of unbalanced pressure pulsating flow and phase change heat transfer, uncontrollable internal working fluid pulsation frequency, unstable operation, etc. Achieve the effect of simple use, convenient production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

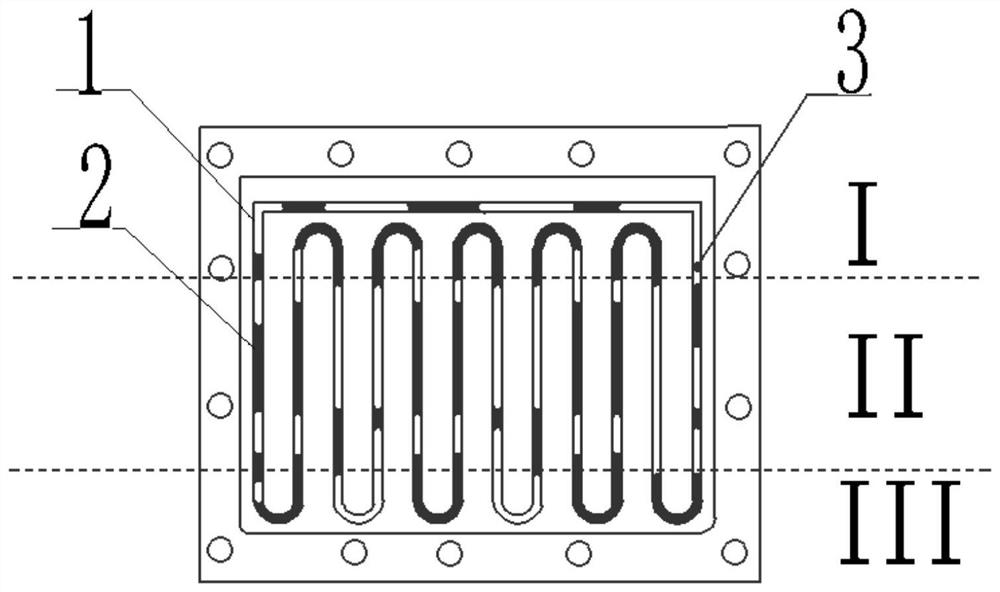

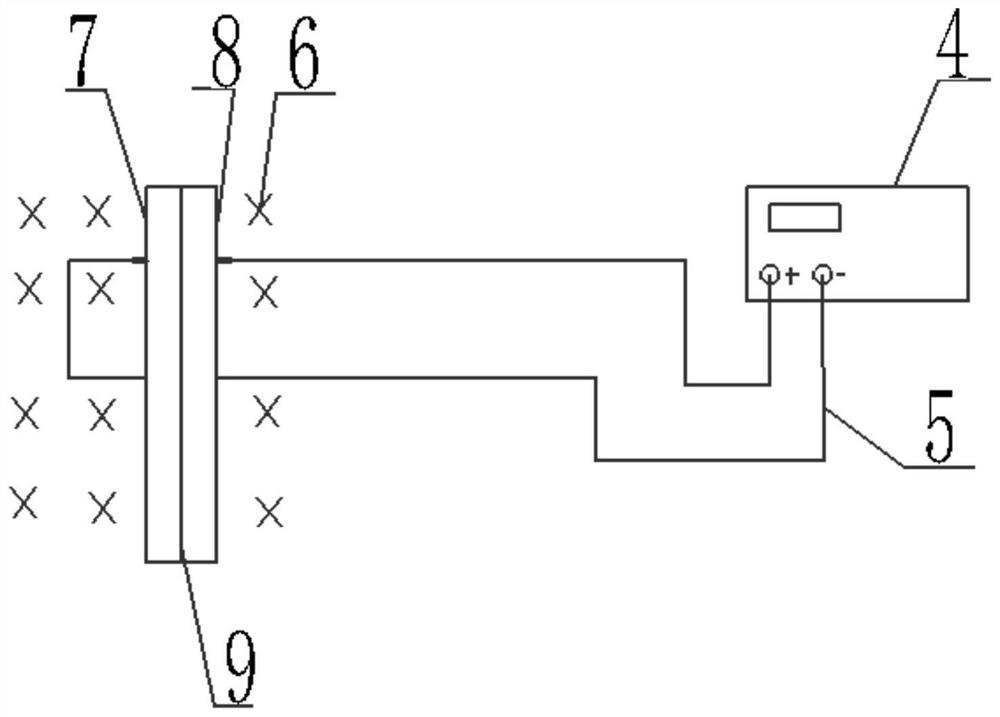

[0023] Such as figure 1 with figure 2 Shown is a controllable plate type pulsating heat pipe heat transfer system with an external oscillation source disclosed in the present invention, including a first cover plate 7 and a second cover plate 8, and the first cover plate 7 and the second cover plate 8 are arranged opposite to each other And between the first cover plate 7 and the second cover plate 8, a working medium channel 1 is processed, and the working medium channel 1 is provided with working medium 2 alternately distributed in the state of vapor plug and liquid plug to form condensation zone I, adiabatic zone II and evaporative zone III, also comprising,

[0024] An insulating sheet 9 disposed between the first cover plate 7 and the second cover plate 8 for electrically insulating the first cover plate 7 and the second cover plate 8;

[0025] A power supply 4 connected to the first cover plate 7 and the second cover plate 8 for generating a pulsed electric field betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com