A controllable tube-type pulsating heat pipe heat transfer system with an external oscillating source

A technology of pulsating heat pipe and heat transfer system, which is applied in the field of controllable tube pulsating heat pipe heat transfer system, can solve problems such as unstable operation and difficult startup, and achieve the effects of convenient manufacture, enhanced heat transfer performance, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

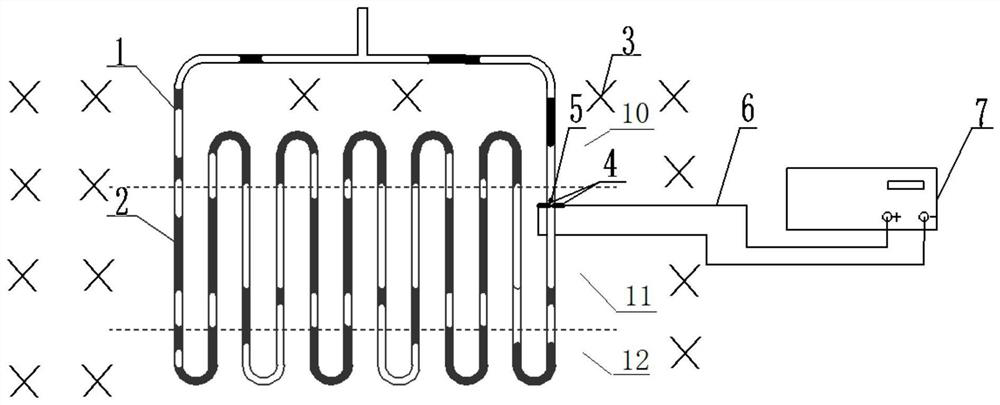

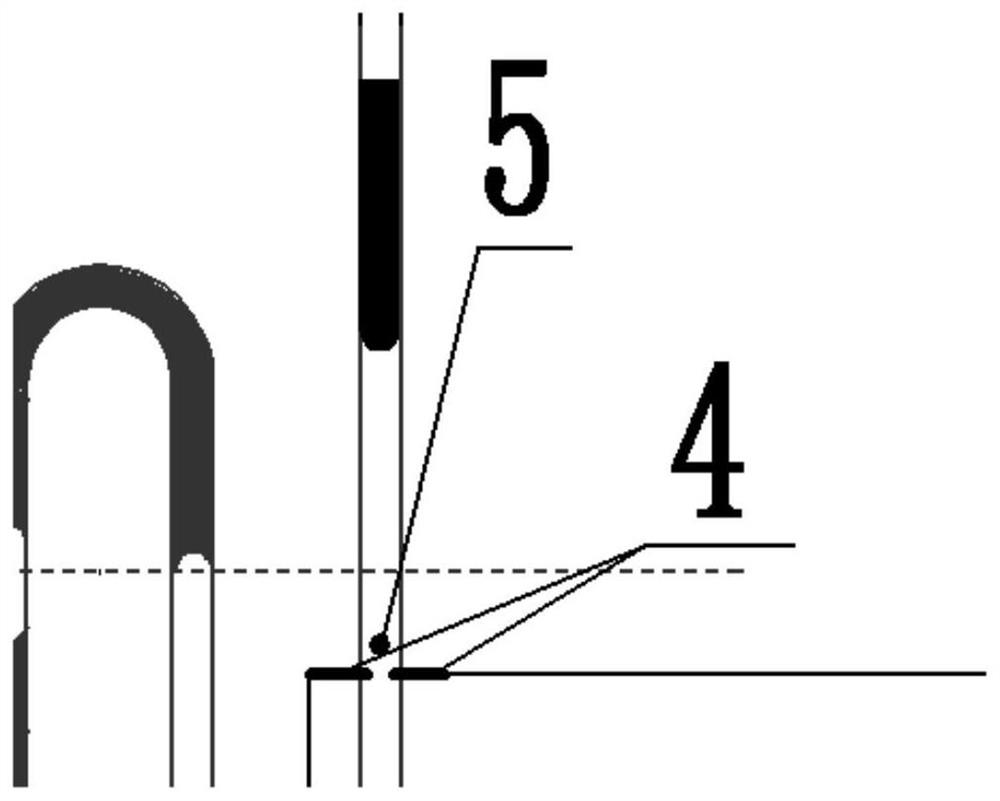

[0027] Such as figure 1 and figure 2 Shown is a controllable tubular pulsating heat pipe heat transfer system with an external oscillation source disclosed in the present invention, which includes a tubular pulsating heat pipe 1 filled with working fluid. The tubular pulsating heat pipe 1 includes a condensation zone I10 and an adiabatic zone II11 And the evaporation zone III12 also includes an external oscillating source for adjusting the pulsation frequency and amplitude of the working fluid inside the tubular pulsating heat pipe.

[0028] Specifically, the tubular pulsating heat pipe 1 is manufactured by bending a capillary tube into a serpentine shape and filling it with a working medium 2 after vacuuming. The working medium in the manufactured pulsating heat pipe is in a state of alternate distribution of vapor plugs and liquid plugs. The pulsating heat pipe is sequentially divided into condensation zone I, adiabatic zone II, and evaporation zone III from top to bottom ...

Embodiment 2

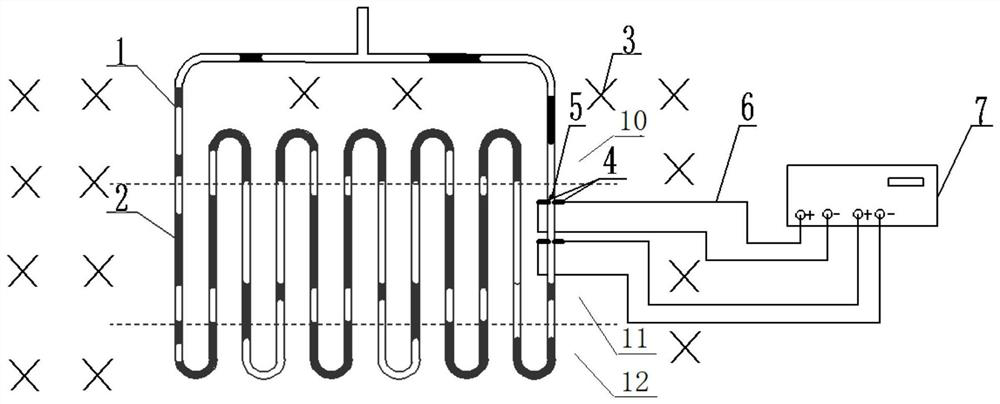

[0038] Such as image 3 and Figure 4Shown is the second embodiment of a controllable tube-type pulsating heat pipe heat transfer system with an external oscillation source disclosed in the present invention. The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the electric field The generating device has multiple groups, and the electrode pairs of the multiple groups of electric field generating devices are arranged at intervals in the tube-type pulsating heat pipe. Similarly, even if there is an electric field arrangement in the entire tube-type pulsating heat pipe, this can make the liquid metal circulate in the tube-type pulsating heat pipe, thereby changing the pulsation frequency and amplitude of the working medium of the pulsating heat pipe.

[0039] In this example, if image 3 and Figure 4 As shown, the electric field generating device has two groups, and the electrode pairs 4 of the two groups of electric field generating devices are a...

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 1 is that, in embodiment 1, the electric field generating device has multiple groups, and the electrode pairs of the electric field generating device in multiple groups are arranged at a certain distance in sequence in the tubular pulsating heat pipe, The polarities of the electric fields generated by multiple sets of electric field generators in the tube-type pulsation heat pipe are the same, that is, the entire tube-type pulsation heat pipe has an electric field arrangement, which can make the liquid metal circulate in the tube-type pulsation heat pipe, and then Change the pulsation frequency and amplitude of the working medium of the pulsating heat pipe.

[0042] In this embodiment, the electric field generating device has one set, and there are multiple sets of electrode pairs in the electric field generating device, and the multiple sets of electrode pairs are arranged at a certain distance in sequence in the tubula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com