Mechanical system and measuring method for measuring sizes of tunnel segment and segment mold

A tunnel segment and mold size technology, which is applied to tunnels, tunnel linings, and measuring devices, can solve the problems of low detection accuracy, difficulty in ensuring detection quality, and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

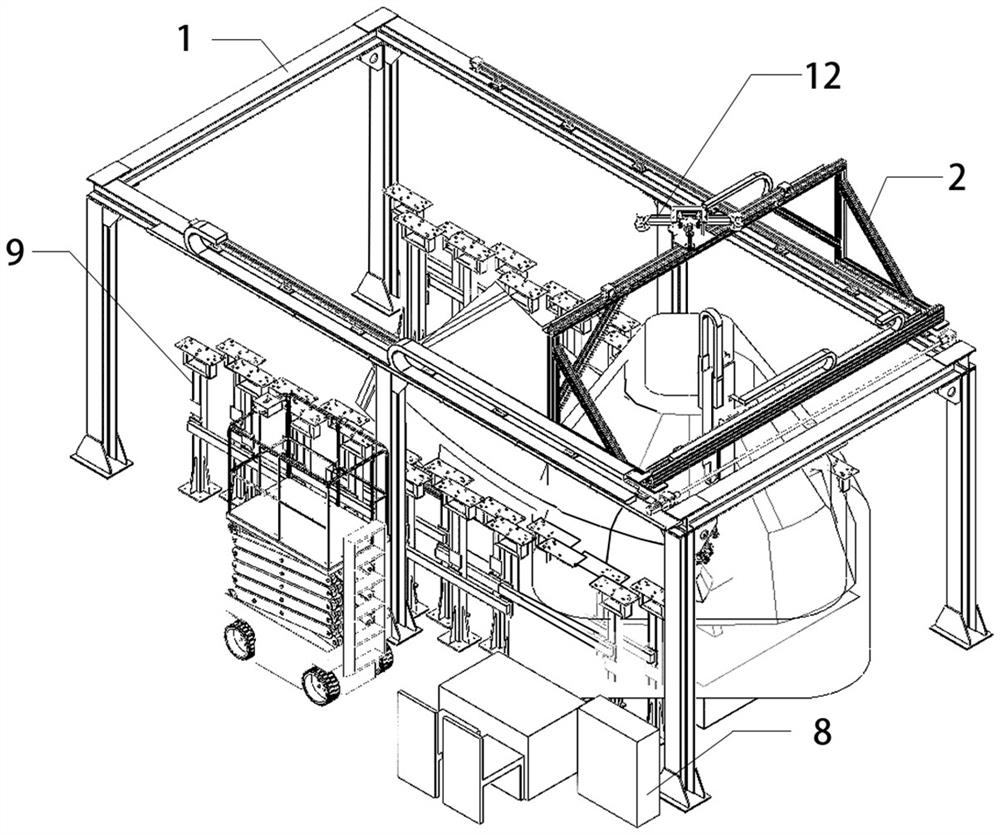

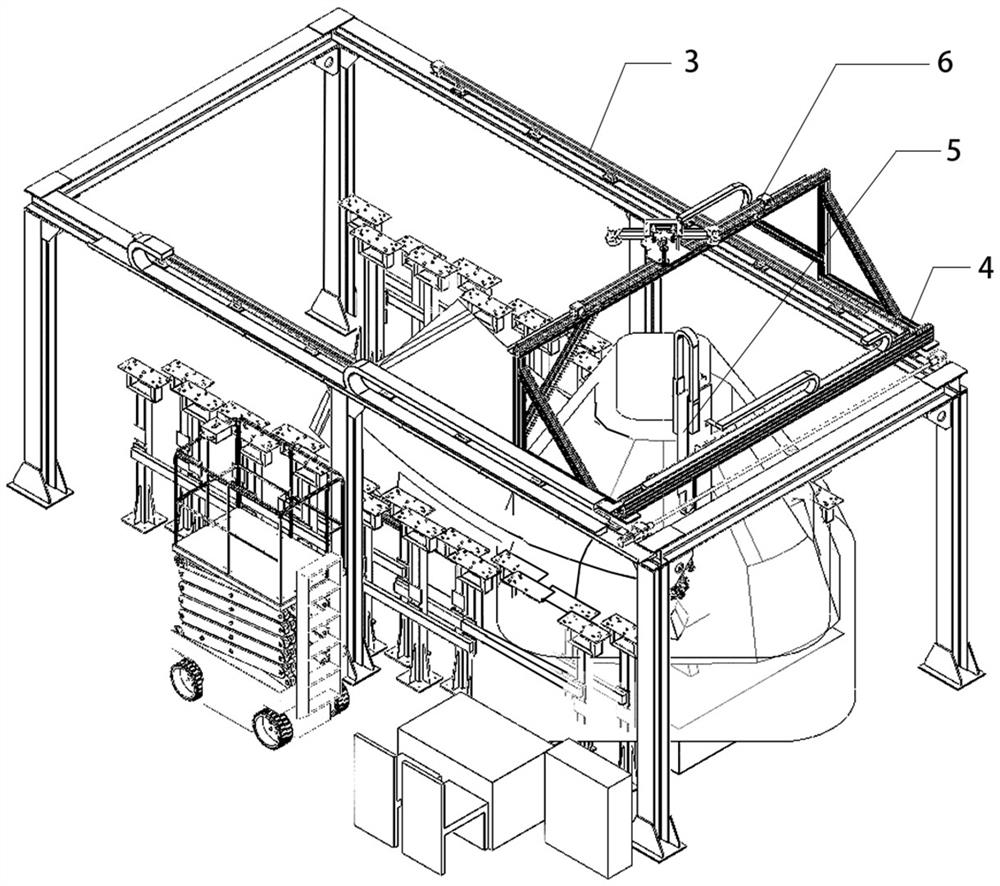

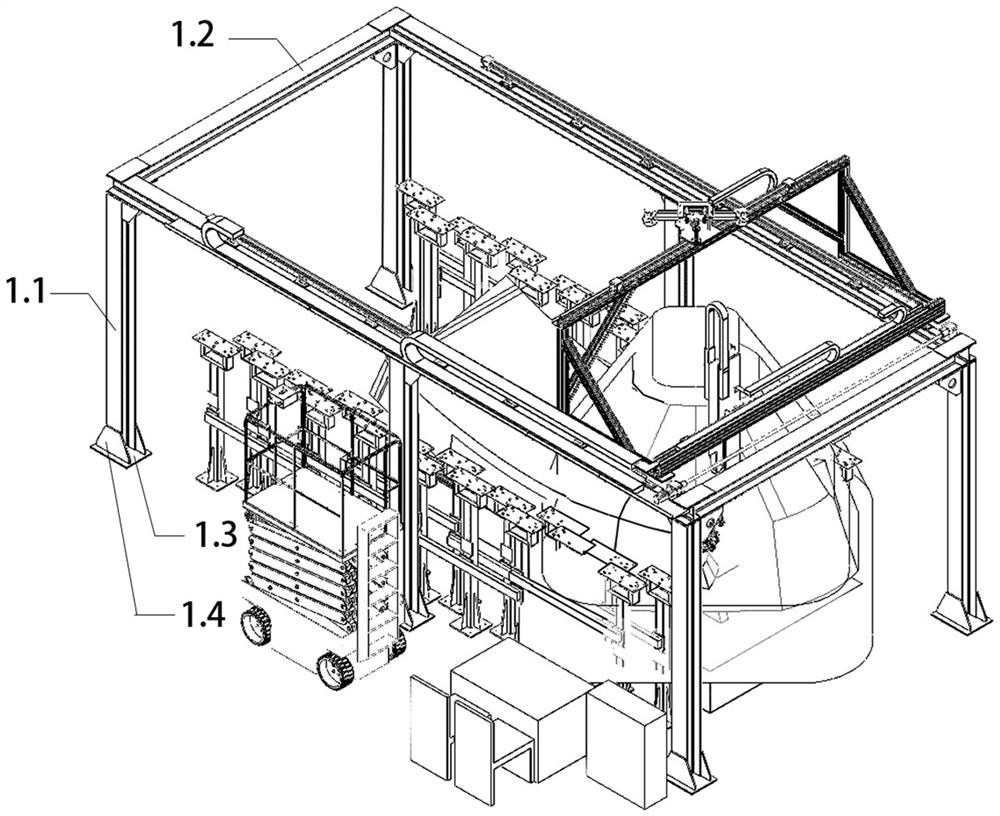

[0048] Examples see Figures 1 to 6 As shown, the mechanical system and measurement method for dimension measurement of tunnel segments and segment molds.

[0049] A mechanical system for dimension measurement of tunnel segments and segment molds, including hardware and software;

[0050]The hardware part includes the truss main body 1, the moving frame main body 2 arranged on the top surface of the truss main body 1, the target 9 arranged on a pair of sides inside the truss main body 1 along the lengthwise direction, and the electrical control cabinet 8 arranged at a corner outside the truss main body 1 And the segment trolley 10 arranged in the truss main body 1; also includes a mechanical coordinate system, the mechanical coordinate system includes the X axis of the system, the Y axis of the system, the Z axis of the system and the X1 axis of the system.

[0051] The main body of the truss 1 includes two sets of pillars 1.1 symmetrically arranged and a rectangular frame 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com