Method for testing vertical permeability characteristic of sand gravel damming material of earth-rock dam

A technology of permeability characteristics and test methods, which is applied in the field of geotechnical tests of water conservancy and hydropower projects, can solve the problems of lack of test methods and equipment, and the inability to measure the permeability characteristics of filling materials, etc., and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0063] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0064] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

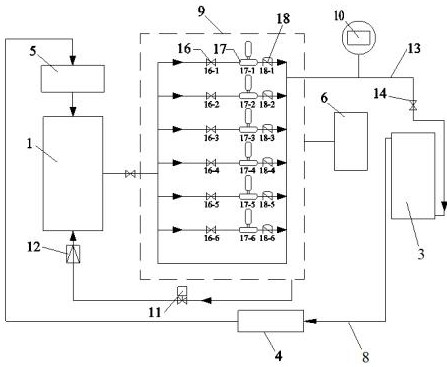

[0066] Such as figure 1 As shown, the invention discloses a method for testing the vertical permeability characteristics of sand and gravel dam materials for earth-rock dams, comprising the following steps:

[0067] Step 1: Determine the size of the permeameter 3, the loading of the permeameter 3, and the maximum head pressure of the water head water supply pressurizing device 2 according to the test requirements;

[0068] Step 2: Perform side wall flow treatment on the inner wall of the permeameter 3;

[0069] Step 3: Prepare samples for the filling material according to the requirements of the penetration test, and pre-embed the pressure measurement extension pipe 29 in the pressure measurement hole 28 of the permeameter 3 during sample preparation;

[0070] Step 4: After sample preparation is completed, install the upstream permeable plate 24 of the permeameter 3, lay buffer material on the upstream permeable plate 24, and then install the hydraulic jack 26 to fasten the p...

Embodiment 2

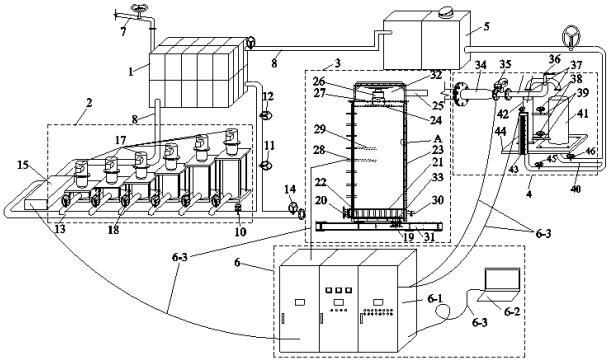

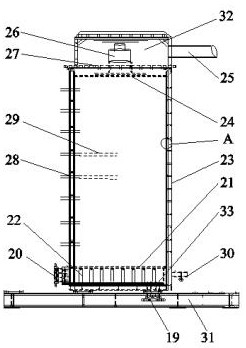

[0075] preferred, such as figure 2 , 3 As shown, in the step 1, the permeameter 3 includes a sand discharge hole 19, a water inlet 20, a downstream permeable plate 21, a support column 22, a sample container 23, an upstream permeable plate 24, an upper cover water outlet 25, a hydraulic jack 26, Force transmission column with holes 27, pressure measuring hole 28, pressure measuring extension tube 29, saturation hole 30, support base 31, sample container upper cover 32 and sample container lower cover 33, the sample container lower cover 33 is installed on the support base 31 upper end surface, wherein the lower end surface of the sample container lower cover 33 is provided with a sand discharge hole 19, the left and right end surfaces of the sample container lower cover 33 are respectively provided with a water inlet 20 and a saturation hole 30, and the inside of the sample container lower cover 33 is vertically provided with The support column 22, the lower end of the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com