Comprehensive evaluation method for corrosion resistance of paint film based on environmental factors

A technology for comprehensive evaluation and corrosion resistance, which is applied in the field of comprehensive evaluation of paint film corrosion resistance based on environmental factors, which can solve the problem of inability to effectively guide the selection of coatings, the inability of coatings to meet the needs of corrosive use environments, and the inability to quantitatively evaluate the corrosion resistance of paint films. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

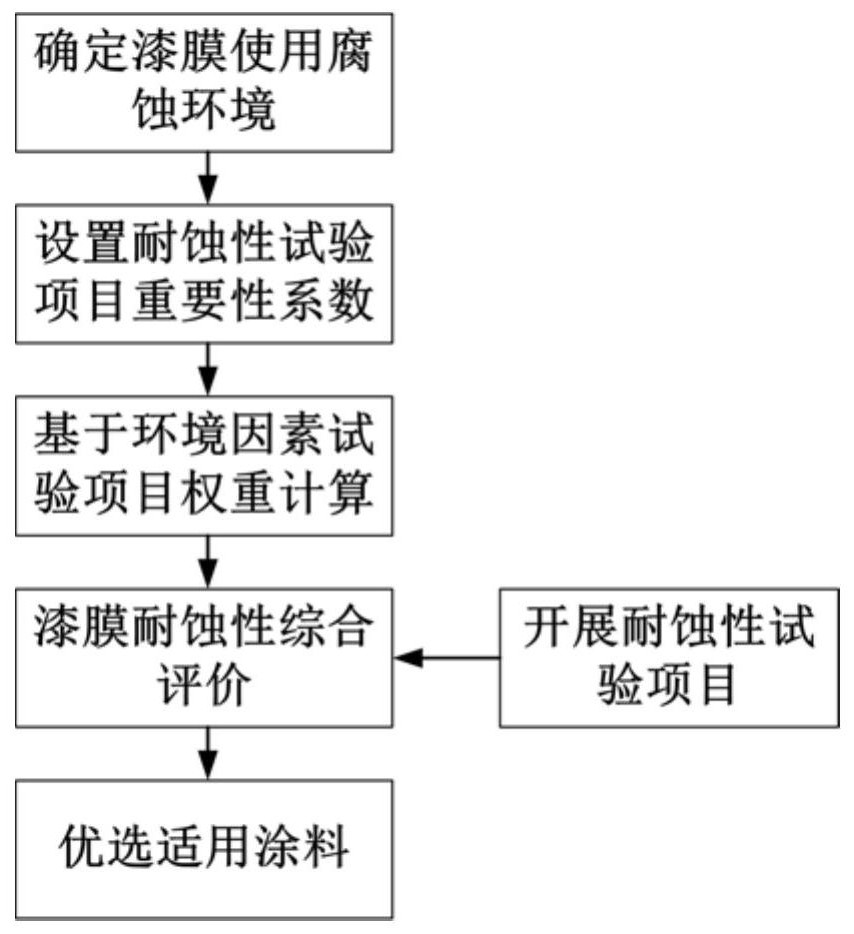

[0030] Taking the use of paint film in construction machinery industry as an example, the evaluation of paint film corrosion resistance mainly includes neutral salt spray test, heat and humidity resistance test, temperature change resistance test, heat resistance test, acid resistance test, alkali resistance test, Salt water resistance test, oil resistance test. The process of comprehensively evaluating the performance of the paint film based on the above tests is as follows: figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com