A Classification Method of Nut Surface Defects Based on EfficientNet

A defect classification and nut technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as low accuracy, poor generalization ability, and low efficiency, and achieve the effect of avoiding time-consuming, enhancing adaptability, and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

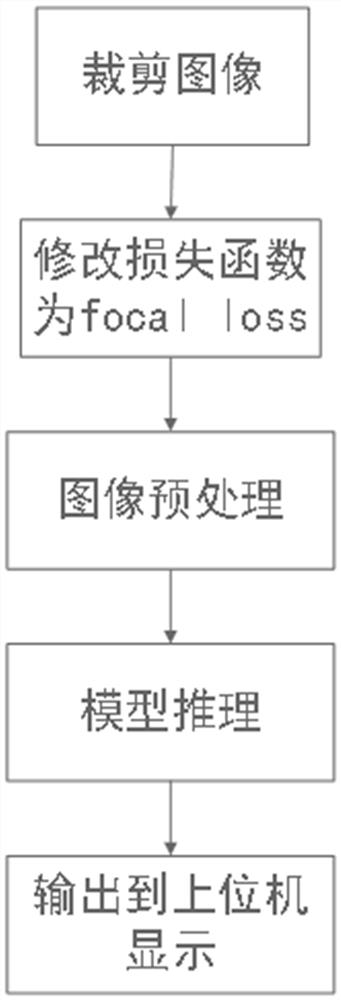

[0033] Classification based on a defect in the nut EfficientNet surface, comprising the steps of:

[0034] Step a: collecting training samples, production data collection; EfficientNet model training, training the model converge, and then classified by a nut face data set;

[0035] Step two: collecting target image, cropping the image of the target;

[0036] Step three: Modify loss function focal loss, adjusting the positive and negative sample weights to enhance the accuracy of the model;

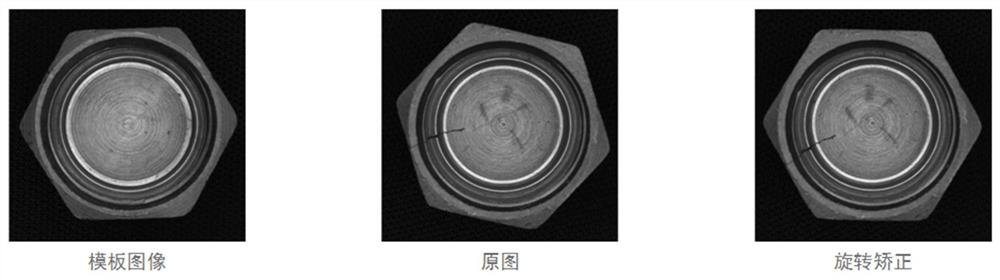

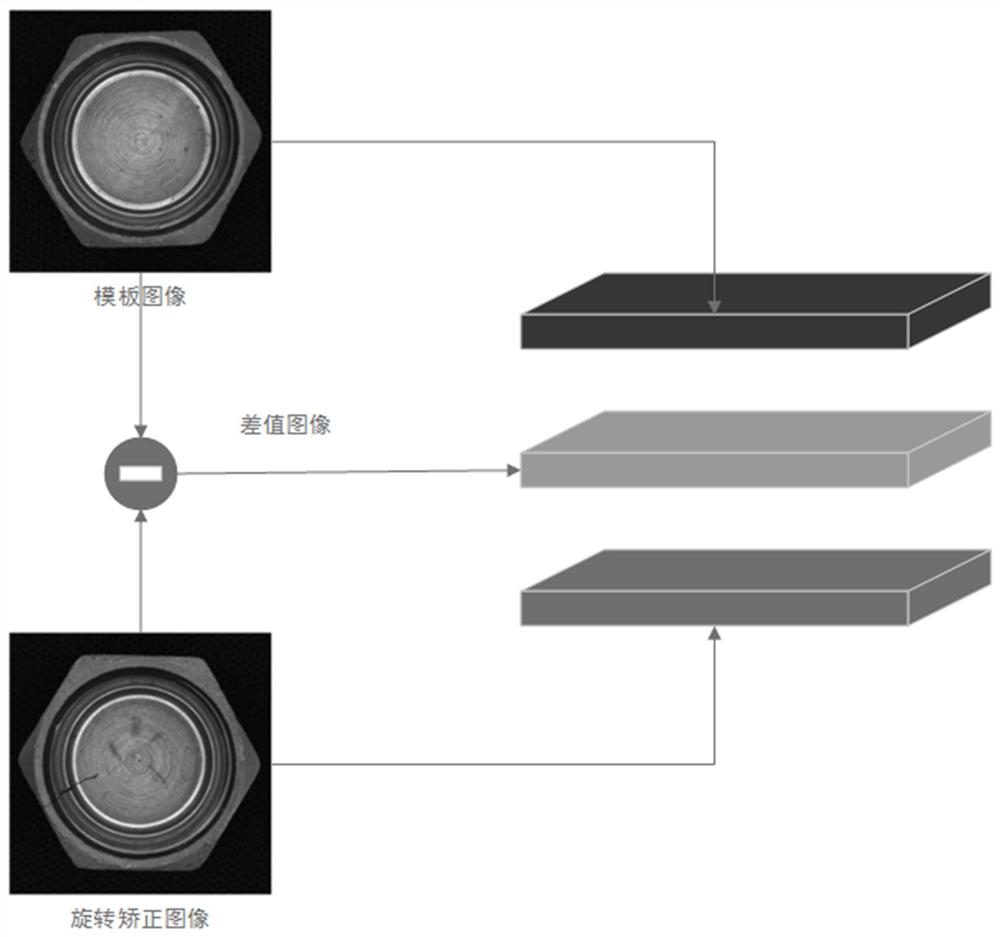

[0037] Step Four: preprocessing the image to prepare a template image rotation correction on the input image, and calculating the difference obtained difference image, as the three three-channel image fusion model as an input image;

[0038] Step Five: model reasoning using reasoning model EfficientNet input image;

[0039] Step Six: inference step 5 outputs the image to the host computer display.

[0040] Specifically, in a step, collecting training samples, production data collection, produc...

Embodiment 2

[0043] Classification based on a defect in the nut EfficientNet surface, comprising the steps of:

[0044] Step a: collecting training samples, production data collection; EfficientNet model training, training the model converge, and then classified by a nut face data set;

[0045] Step two: collecting target image, cropping the image of the target;

[0046] Step three: Modify loss function focal loss, adjusting the positive and negative sample weights to enhance the accuracy of the model;

[0047] Step Four: preprocessing the image to prepare a template image rotation correction on the input image, and calculating the difference obtained difference image, as the three three-channel image fusion model as an input image;

[0048] Step Five: model reasoning using reasoning model EfficientNet input image;

[0049] Step Six: inference step 5 outputs the image to the host computer display.

[0050] Specifically, in step II and then input to resize the image by a method using the crop m...

Embodiment 3

[0052] Classification based on a defect in the nut EfficientNet surface, comprising the steps of:

[0053] Step a: collecting training samples, production data collection; EfficientNet model training, training the model converge, and then classified by a nut face data set;

[0054]Step 2: Collect the target image, crop the target image;

[0055] Step 3: Modify the loss function is Focal LOSS, adjust the positive and negative sample weight, improve the accuracy of model;

[0056] Step 4: The image preoperation is made, and the template image rotates the input image, and the difference is obtained, and the three is fused into a three-channel image as a model input image;

[0057] Step 5: Model reasoning, use the EfficientNet model to reason to introduce the input image;

[0058] Step Six: Output the image output to the host computer display in step five.

[0059] Specifically, in industrial production, the probability of defective products is small, and the normal samples typically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com