A system calibration method for a three-dimensional line-of-sight tracking system

A technology of eye tracking and system calibration, applied in the field of computer vision, can solve the problem that the light source and the screen are not within the field of view of the system camera, and achieve the effect of good calibration requirements, convenient operation and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to make the objects, technical solutions, and advantages of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

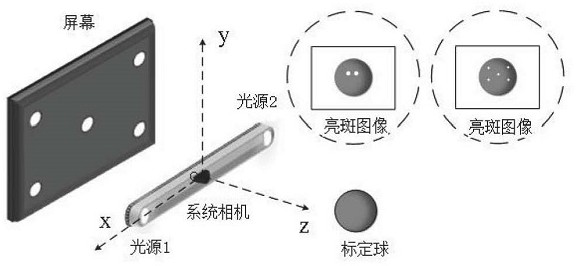

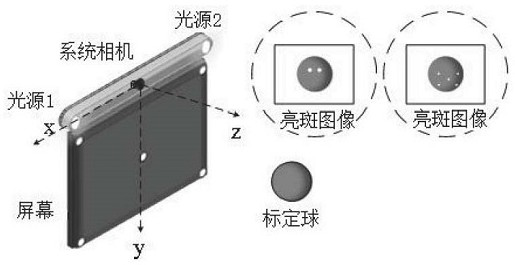

[0082] Embodiments of the present invention provide a system calibration method for a three-dimensional view line tracking system, such as figure 1 As shown, the method includes the following steps:

[0083] Calibrate the system camera to obtain internal parameters of the system camera, including focal length, like the main point, like the original size, distortion parameters, etc.

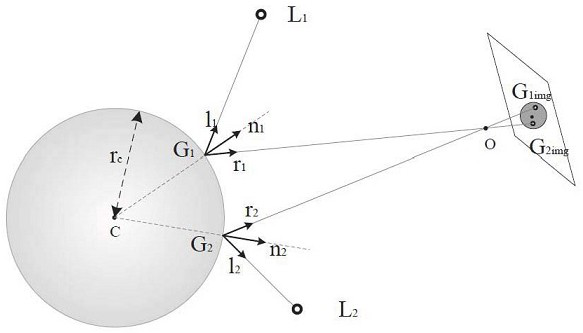

[0084] Place the calibration ball in the field of view of the system camera, shoot the shot image formed on the reflection on the ball and calibration ball;

[0085] Change the position of the laminated ball, shoot the calibration ball and shot image of multiple groups;

[0086] According to the spherical heart and shot coordinates of different positions, construct a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com