A robot tcp calibration system based on vertical reflection

A calibration system and vertical reflection technology, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inefficiency and collision, and achieve the effect of low cost, high safety factor, and meeting the needs of calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

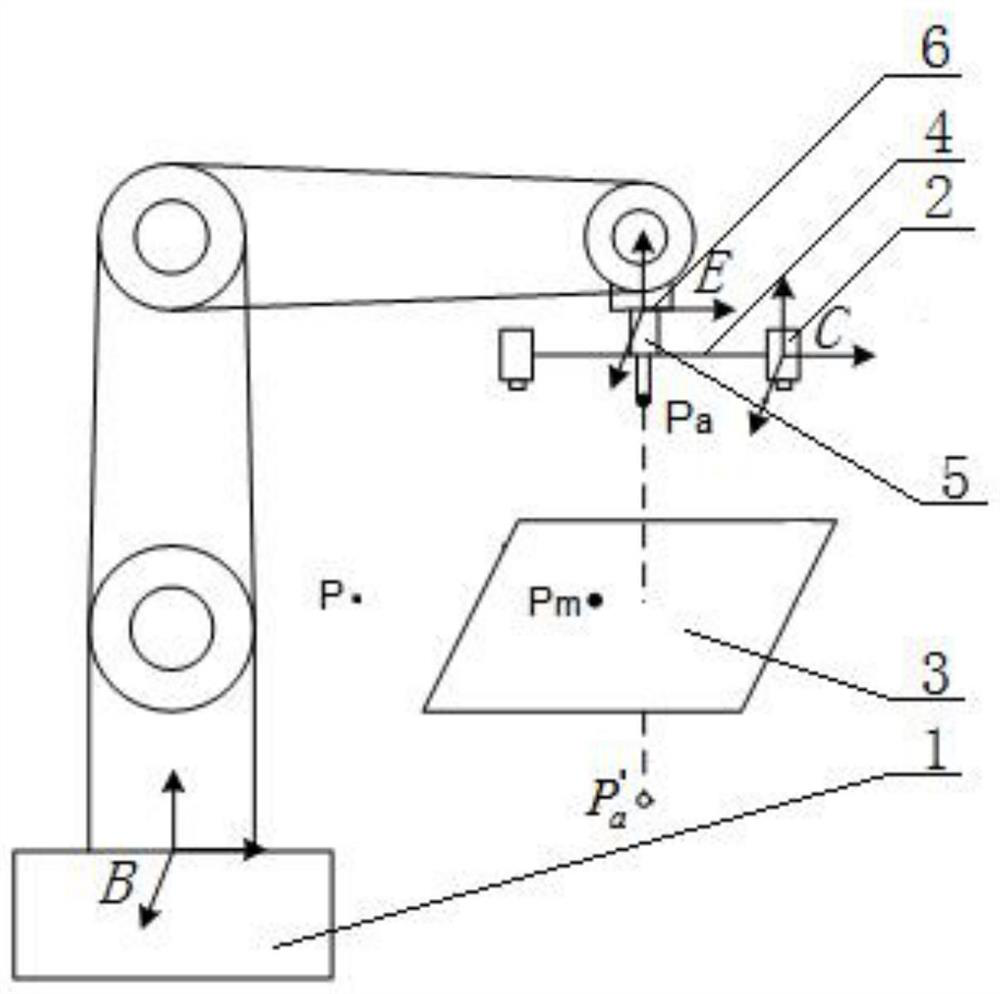

[0055] Such as figure 1 As shown, the embodiment of the present invention discloses a robot TCP calibration method based on vertical reflection, comprising the following steps:

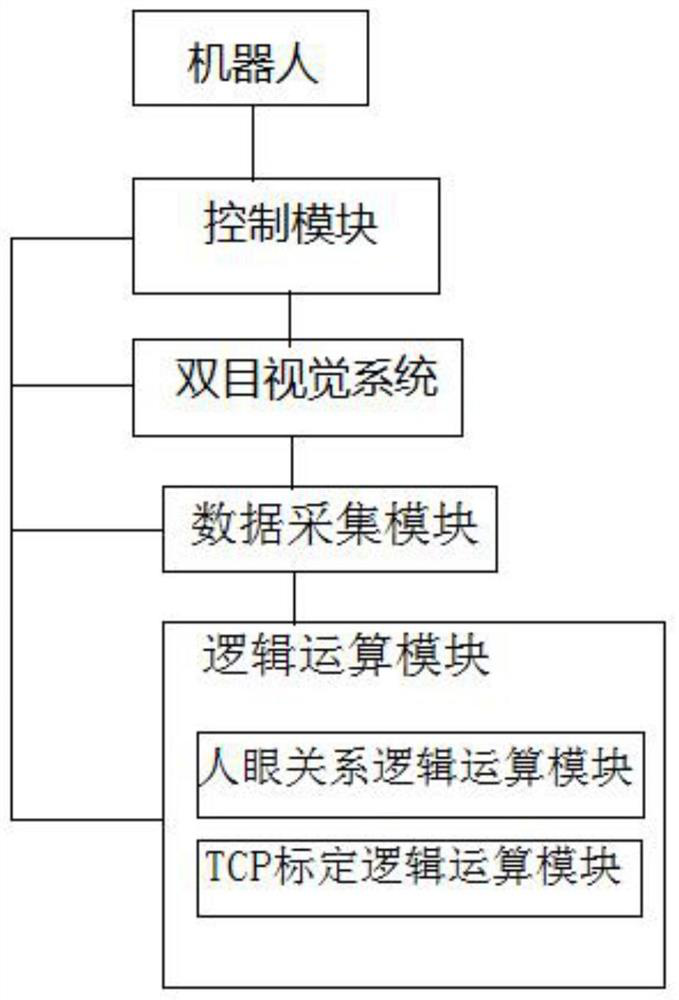

[0056] (S1) Establish the binocular vision system coordinate system {C} on the binocular vision system; establish the robot end coordinate system {E} at the robot end 6, and determine the binocular vision system coordinate system {C} relative to the robot end coordinate system { The transformation matrix of E} For robot hand-eye relationship.

[0057] In this embodiment, in step (S1), the specific steps are:

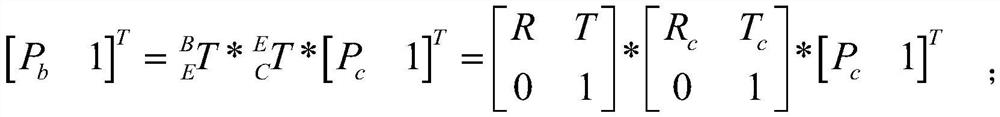

[0058] (S101) establish the robot hand-eye relationship as Among them, R C It is the rotation matrix converted from the end coordinate system {E} of the robot and the coordinate system {C} of the binocular vision system and is a fixed value; T C is the translation vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com