Full-automatic pipe cutting machine

A pipe cutting machine, fully automatic technology, applied in the direction of pipe shearing device, shearing device, shearing machine accessories, etc., can solve the problems of slippage of feeding material, poor feeding accuracy, etc., and achieve reliable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

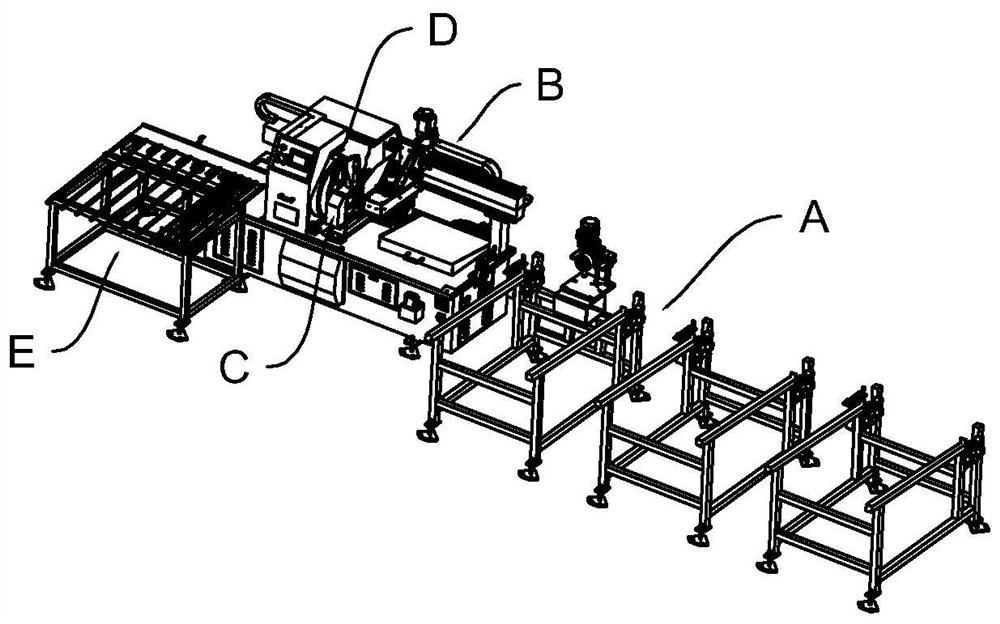

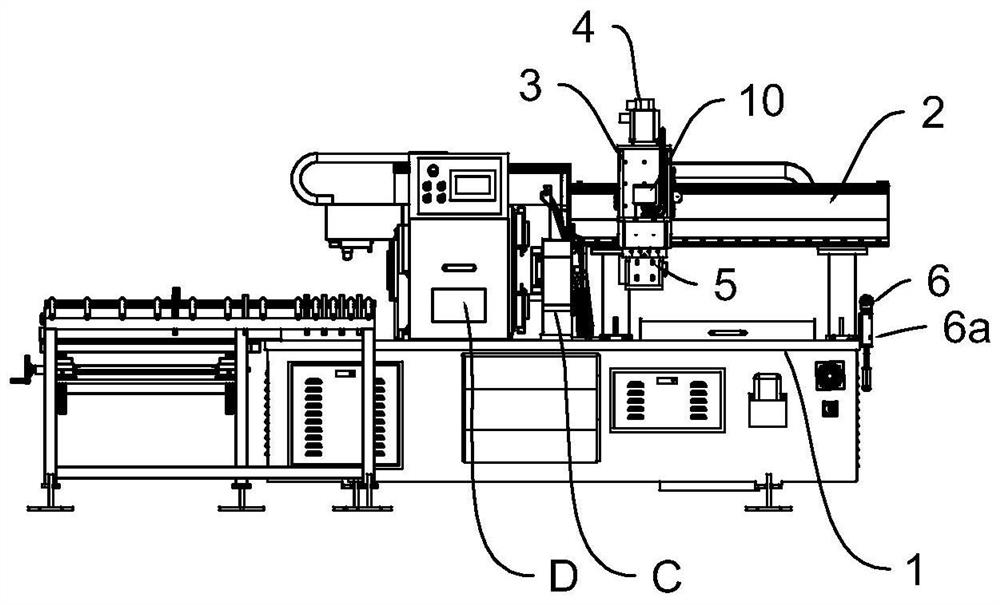

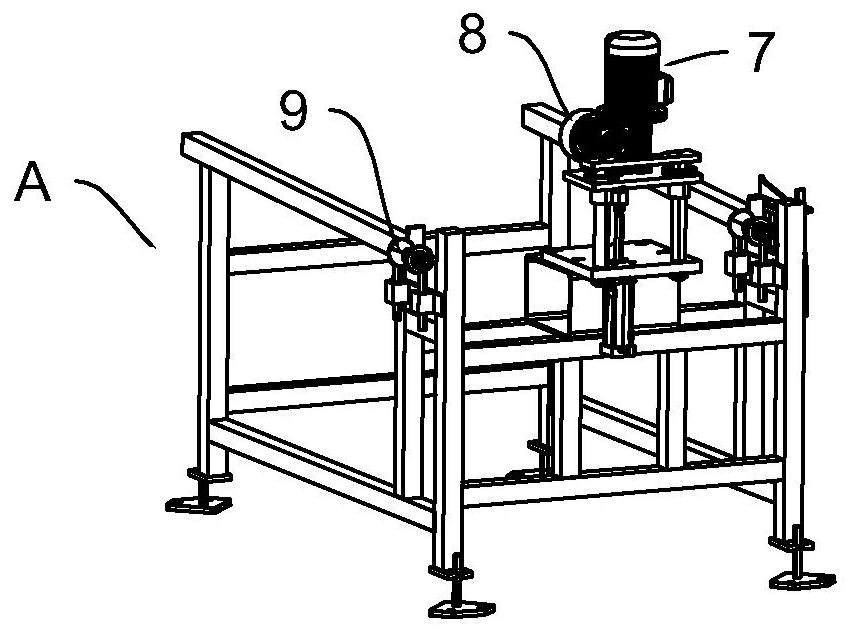

[0022] A fully automatic pipe cutting machine, combined with figure 1 , figure 2 and Figure 9 , including a cutting knife seat D for cutting pipes, the cutting knife seat D is installed on the workbench 1, one end of which is a material inlet 13, and the other end is a material outlet. The mechanism internal structure principle of the cutter seat D is the same as that of the prior documents CN111975091A and CN106077793B. Wherein, the discharge port end is correspondingly provided with a blanking rack E, and the 13 ends of the feed port are provided with a clamping mechanism C, a hanging clamp mechanism B and a loading rack A in sequence. Wherein, both the clamping mechanism C and the hanging clamp mechanism B are installed on the workbench 1 . The clamping mechanism C is provided with a hole-shaped clamping port 12...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap