Operation method of detachable mold trolley device for autoclaved aerated concrete block side plates

A concrete block and autoclaved aerated technology, which is applied in the direction of mold fixtures, molds, mold auxiliary parts, etc., can solve the problem that the autoclaved aerated concrete block is not easy to take out, which is unfavorable for the production and transportation of autoclaved aerated concrete blocks Difficult cutting lines and other problems, to achieve the effect of easy cutting operation, novel structure, and easy splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

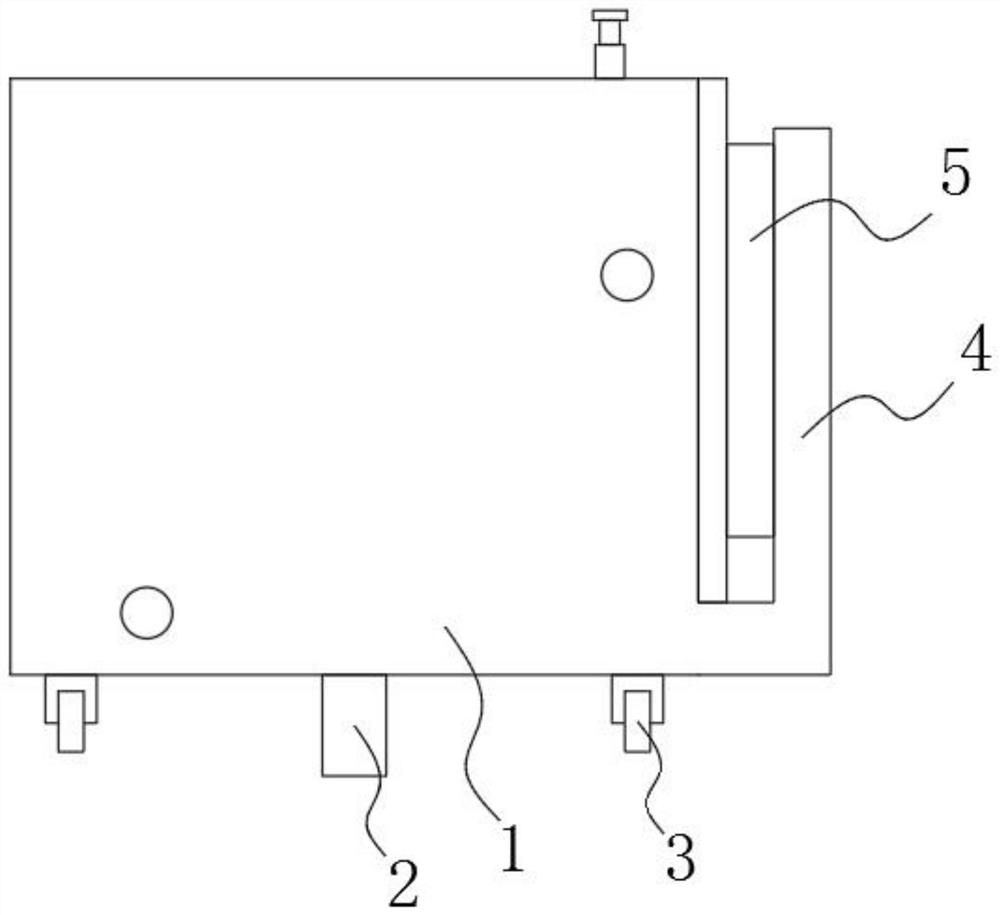

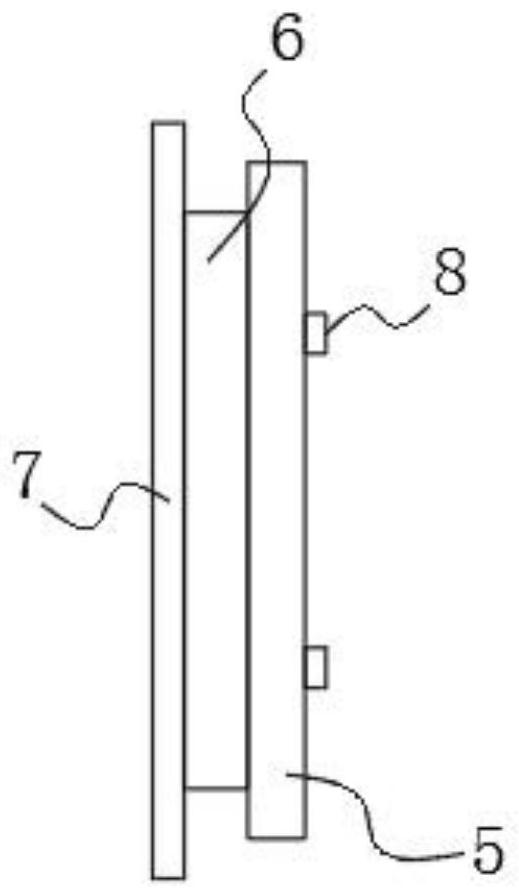

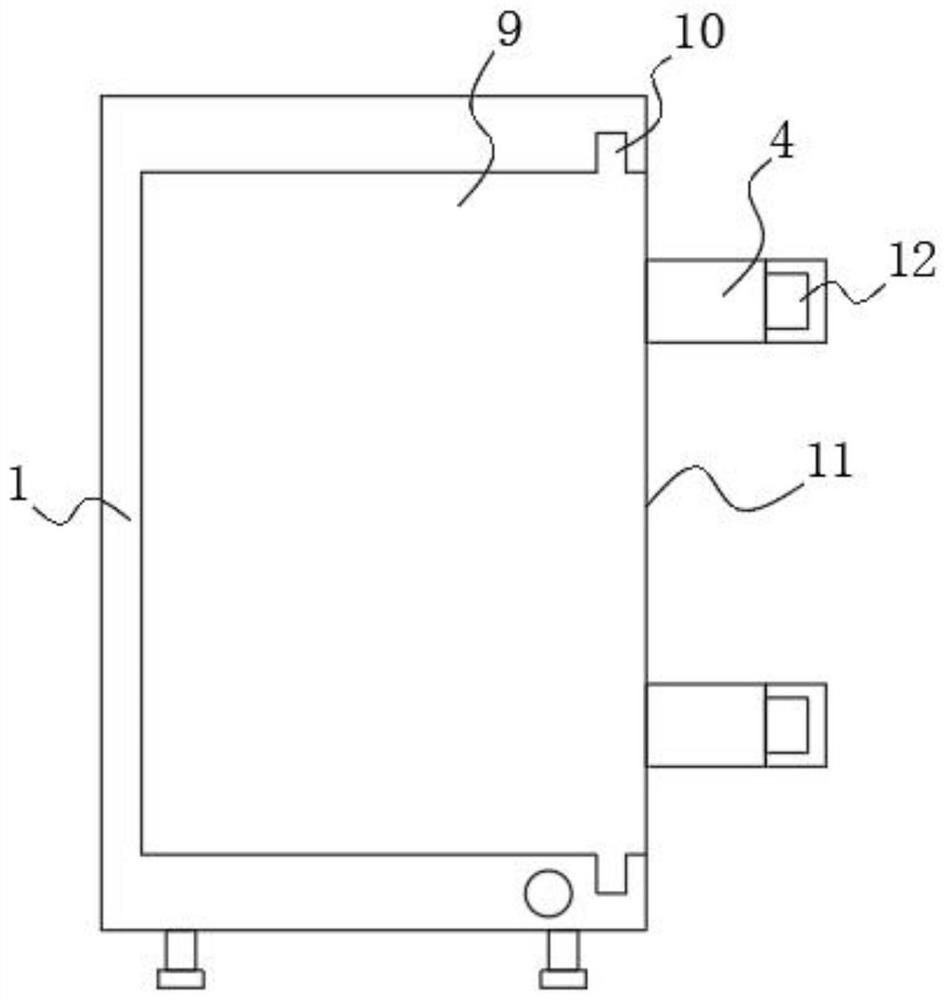

[0018] Attached below Figure 1-3 The specific implementation manner of the present invention will be described in further detail.

[0019] Example, by Figure 1-3 Given, the present invention provides a method for operating a detachable mold vehicle device for the side plate of an autoclaved aerated concrete block, including a bottom vehicle 1, a lower running line 2, a roller 3, a side guard frame 4, a side bottom vehicle 5, a transition Block 6, side baffle plate 7, limit block 8, inner cavity 9, card slot 10, side opening 11, limit groove 12, side running line 13 and connecting block 14, the middle part of the bottom end of the bottom car 1 is provided with a down running line 2. Several rollers 3 are installed at the bottom of the bottom car 1 close to both ends. Two side guards 4 are symmetrically welded on the bottom of one side of the bottom car 1. The inner side of the side guard 4 is provided with a side bottom car 5, and the side bottom One side of the car 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com