980mpa grade cold-rolled alloyed galvanized quenched partition steel and preparation method thereof

A quenching and partitioning, 980mpa technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve problems such as uneven bainite phase structure, increased alloy cost, unfavorable uniform strain distribution in the hole expansion stage, etc. , to achieve the effect of high uniformity of structure, low production cost and high yield force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

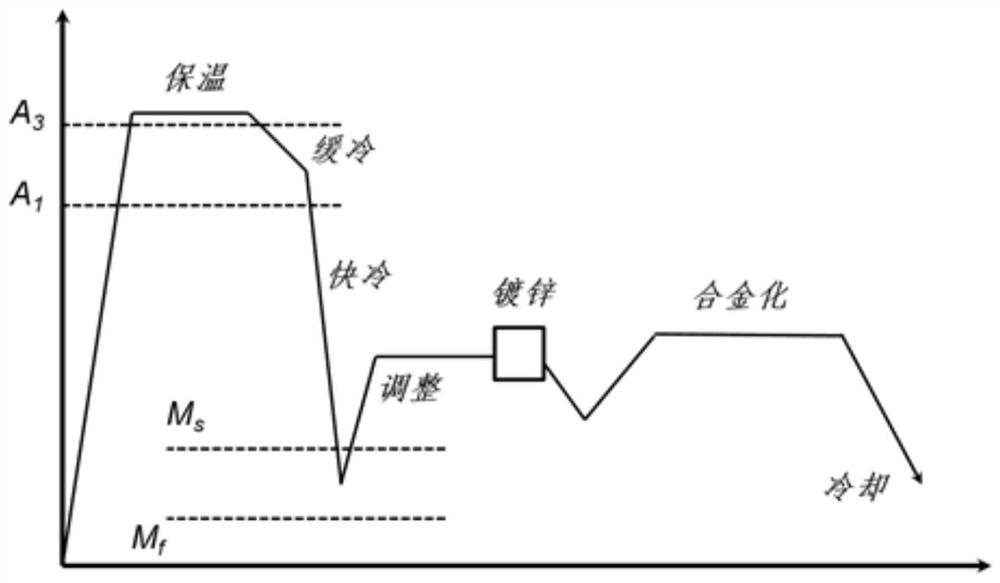

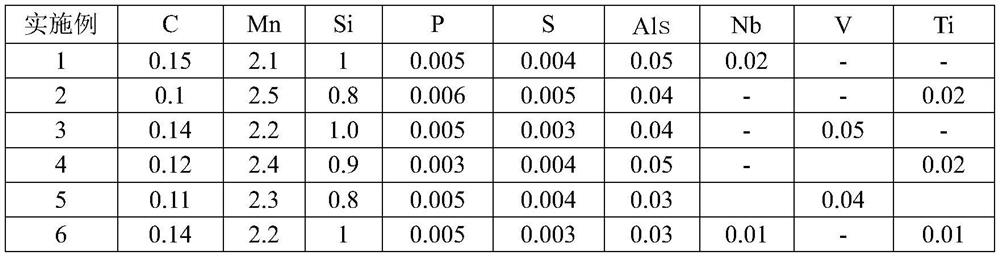

[0033] A method for preparing 980MPa grade cold-rolled, alloyed, galvanized, quenched and distributed steel, wherein the production process of the steel comprises: smelting, hot continuous rolling, pickling cold-rolling, and alloyed galvanizing; wherein:

[0034] 1) Smelting:

[0035] Converter smelting to obtain molten steel that meets the requirements of chemical composition; the molten steel temperature is 1550-1650 °C;

[0036] 2) Hot continuous rolling:

[0037] The heating temperature is 1250~1300℃; two-stage controlled rolling is adopted, that is, rolling in the recrystallization zone + rolling in the non-recrystallization zone, the recrystallization rolling temperature is above 1050℃, and the cumulative deformation is above 50%; no recrystallization The rolling temperature in the zone is above 900°C, and the cumulative deformation is above 70%; after rolling, the temperature is 600-650°C for coiling;

[0038] 3) Pickling and cold rolling:

[0039] Before cold rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com