Novel translation type hydraulic vulcanizing machine

A translational vulcanizing machine technology, applied to tires, other household appliances, household appliances, etc., can solve problems such as unfavorable use, danger of vulcanizing machine, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

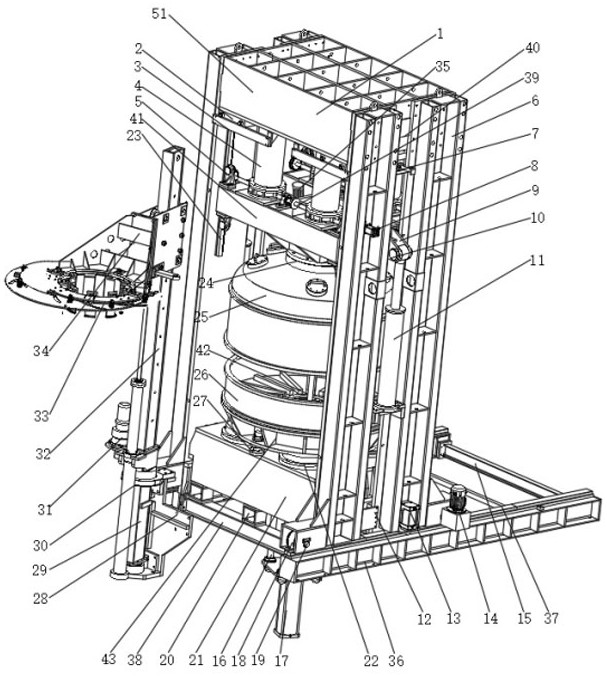

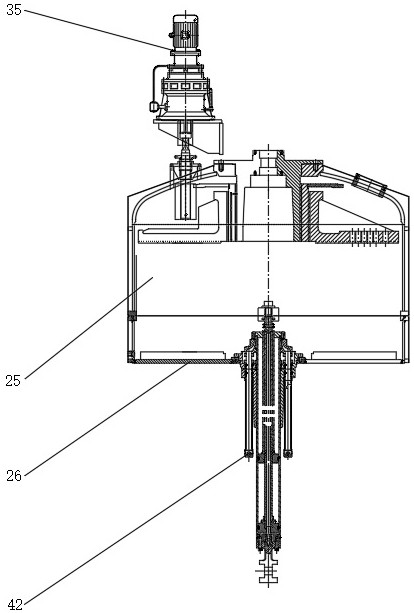

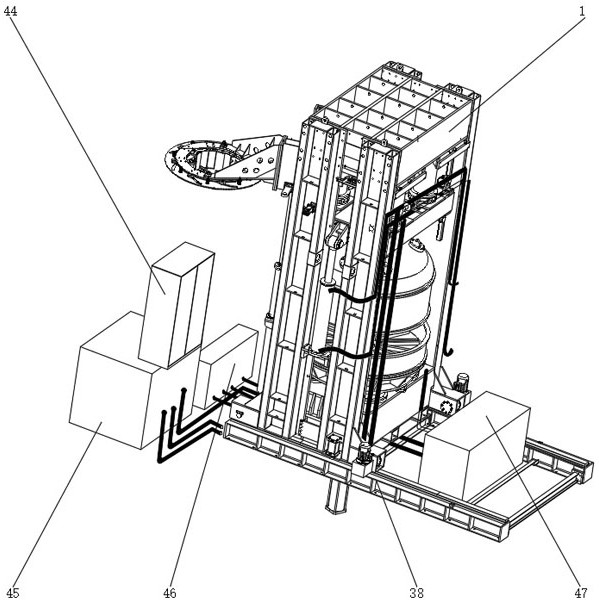

[0020] Such as Figure 1-4 As shown, a new translational hydraulic vulcanizing machine includes a frame body 51, the frame body 51 includes an upper beam 1 and a lower beam 21, and the inside of the upper beam 1 is provided with a cushion 24, an upper steamer 25, and a central mechanism 42 , the lower steamer 26, the lower platform guide 27, the lower platform 43, the oil cylinder 22, the upper side of the upper beam 1 is provided with a synchronous rack 23, an upper platform 41, an upper platform guide 5, a column 4, a roof guide rail 3, and an upper roof 2 , Die-adjusting motor 35, upper beam guard plate 40, synchronous shaft device 39, side plate 6, roof cylinder 7, safety cylinder 8, upper platform support 9, lifting cylinder pin 10, lifting cylinder 11.

[0021] Further, the lower end of the upper beam 1 is provided with a bottom beam connection 38, a pillar 20, a lower beam 21, a support rod 16, a roller 18, a roller shaft 19, a lower ring cylinder 17, a rail beam 36, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com