Head-up display glass and head-up display system

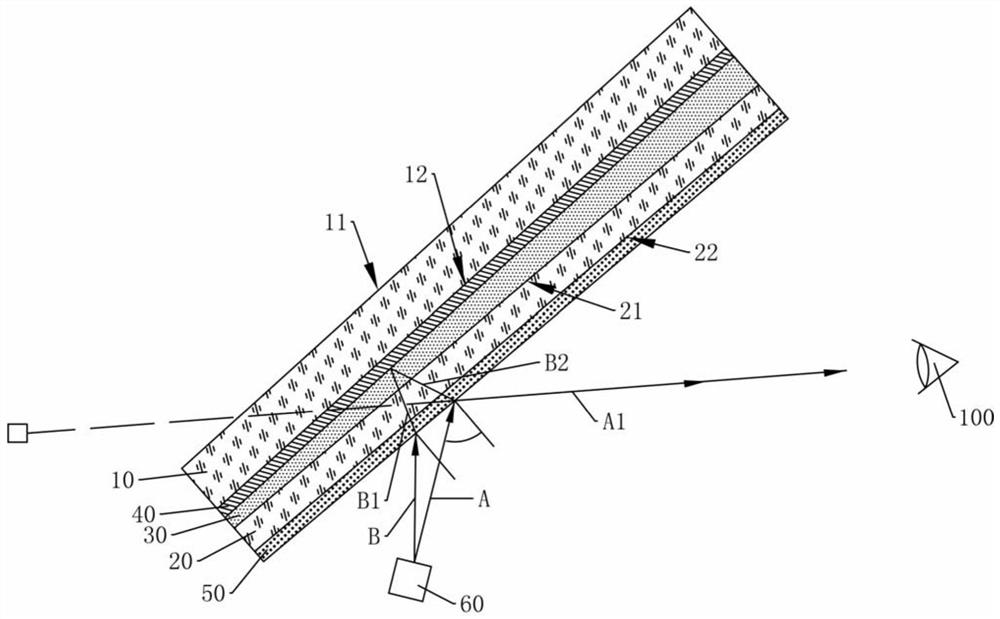

A head-up display system and head-up display technology, applied in the field of head-up display, can solve problems such as limited reflectivity, blurring, and poor display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

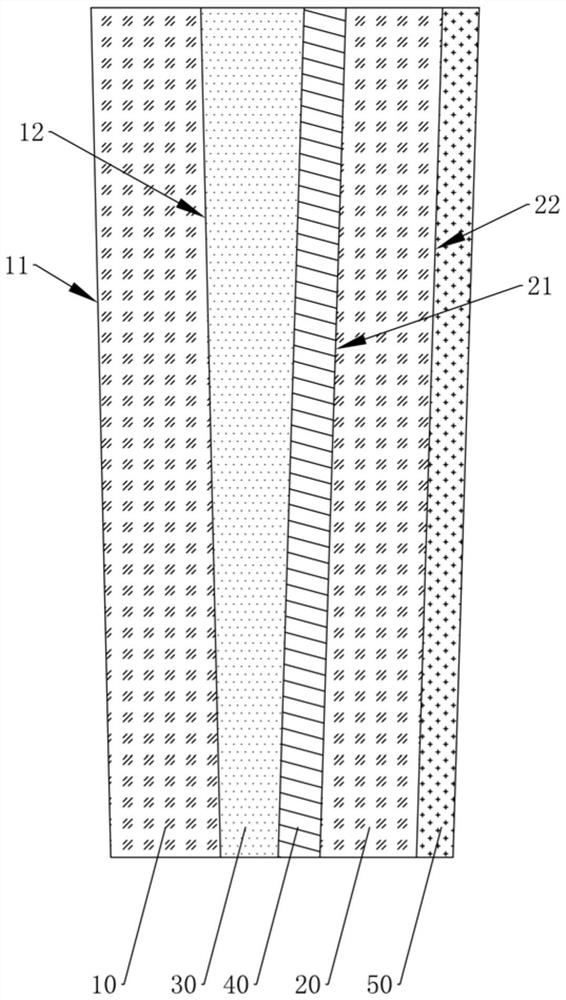

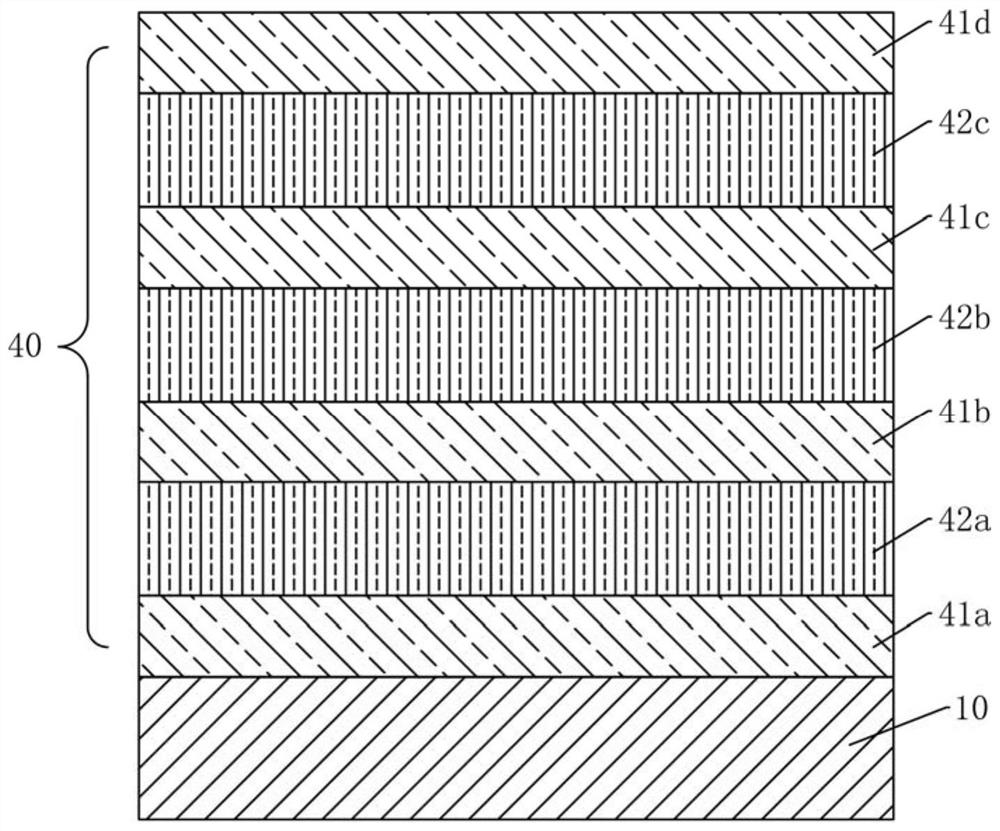

[0083] Head-up display glass: outer glass plate (2.1mm transparent glass) / transparent conductive film / 0.76mm wedge-shaped PVB / inner glass plate (2.1mm transparent glass) / increased reflection film

[0084] Transparent conductive film: 2.1mm transparent glass / ZnSnOx: Mg(15nm) / ZnO: Al(11nm) / Ag(12nm) / ZnO: Al(23nm) / TiOx(2nm) / ZnSnOx: Mg(26nm) / ZnO: Al (26nm) / Ag(13nm) / ZnO:Al(23nm) / TiOx(3nm) / ZnSnOx:Mg(24nm) / ZnO:Al(25nm) / Ag(11nm) / ZnO:Al(9nm) / TiOx(2nm ) / ZnSnOx:Mg(18nm) / SiN(13nm)

[0085] Wedge PVB: wedge angle = 0.29mard

[0086] Enhanced reflection coating: 2.1mm transparent glass / ZnSnOx: Mg(38nm) / TiOx(58nm) / SiO2(96nm)

Embodiment 2

[0088] Head-up display glass: outer glass plate (2.1mm transparent glass) / transparent conductive film / 0.76mm wedge-shaped PVB / inner glass plate (1.1mm transparent glass) / increased reflection film

[0089] Transparent conductive film: consistent with embodiment 1

[0090] Wedge PVB: wedge angle = 0.18mard

[0091] Enhanced reflection coating: 1.1mm transparent glass / ZnSnOx: Mg(38nm) / TiOx(58nm) / SiO2(96nm)

Embodiment 3

[0093] Head-up display glass: outer glass plate (2.1mm transparent glass) / transparent conductive film / 0.76mm equal thickness PVB / inner glass plate (0.7mm transparent glass) / increased reflection film

[0094] Transparent conductive film: 2.1mm transparent glass / ZnSnOx: Mg(16nm) / ZnO: Al(11nm) / Ag(9nm) / ZnO: Al(22nm) / TiOx(2nm) / ZnSnOx: Mg(26nm) / ZnO: Al (27nm) / Ag(12nm) / ZnO:Al(24nm) / TiOx(3nm) / ZnSnOx:Mg(24nm) / ZnO:Al(23nm) / Ag(12nm) / ZnO:Al(10nm) / TiOx(2nm ) / ZnSnOx:Mg(14nm) / ZnO:Al(10nm) / Ag(10nm) / ZnO:Al(20nm) / TiOx(2nm) / ZnSnOx:Mg(20nm) / SiN(15nm)

[0095] Equal thickness PVB: wedge angle = 0

[0096] Enhanced reflection coating: 0.7mm transparent glass / ZnSnOx: Mg(38nm) / TiOx(58nm) / SiO2(96nm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com